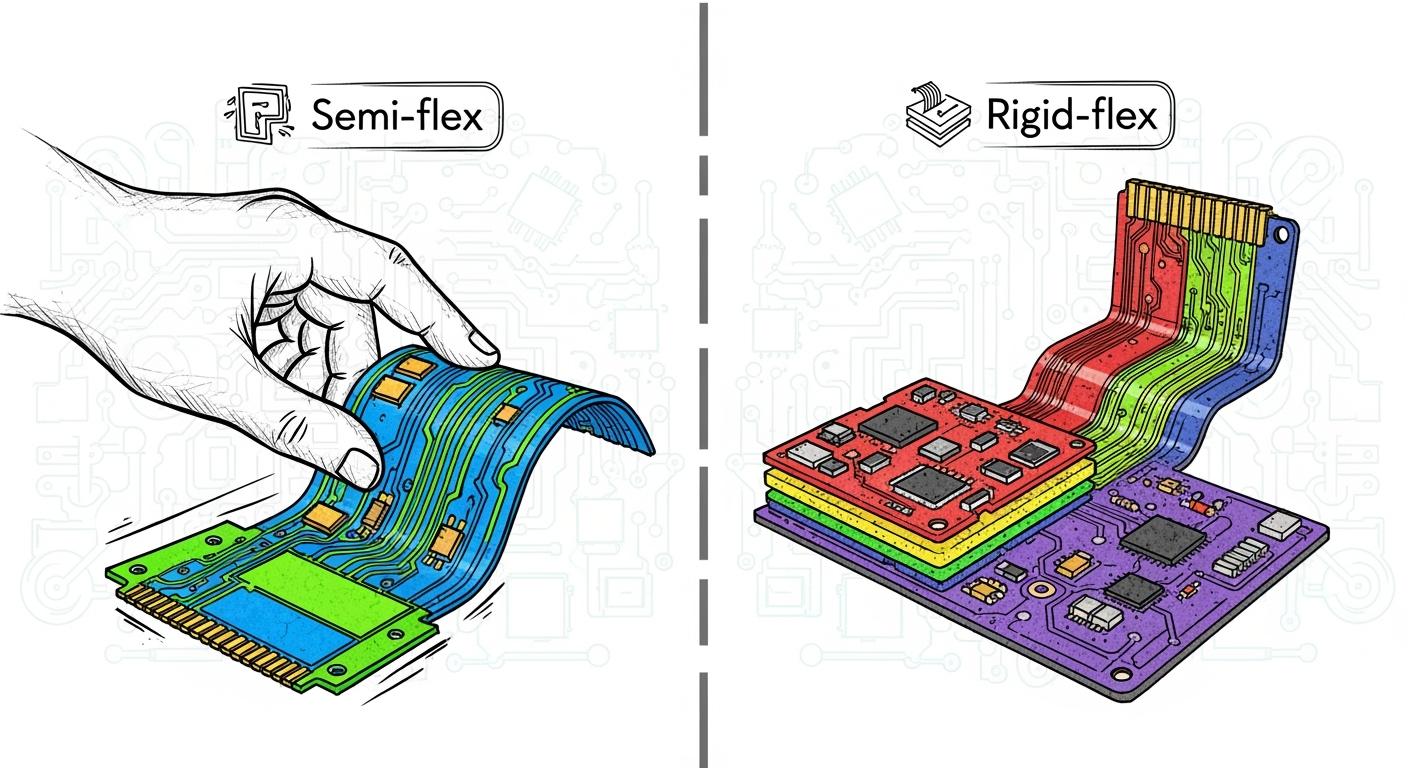

You should know the main differences between semi-flex and rigid-flex PCBs to make good design choices. Semi-flex PCBs can bend, but only in certain spots. Rigid-flex PCBs have hard parts and flexible layers, so they can move more. If you use flex and rigid-flex PCBs, you may have problems like trace thickness, bending radius, and how strong the board is when bent. Look at the table below to see common problems people face:

| Challenge | Description |

|---|---|

| Trace Thickness | Thicker traces make the board less flexible and add stress when you bend it. |

| Bending Radius | The middle line moves, which changes how many copper layers you need. |

| Durability Under Stress | Bending the board many times can make the copper hard and cause the trace to break. |

| Margin of Safety | You need to follow the smallest bend radius to keep the board working for a long time. |

Knowing these things helps you pick the best Multi-layer Flex Rigid PCB for your project.

Key Takeaways

- Semi-flex PCBs can bend only in certain spots. This makes them good for small spaces. But they are not good if you need to bend them many times.

- Rigid-flex PCBs have both hard and bendable layers. They can bend often. This makes them great for things that move a lot.

- You should pick the right PCB type for your project. Think about how much you need it to bend, your budget, and how much space you have.

- Think about how long the PCB will last. Rigid-flex PCBs might cost more at first. But they last longer and work better over time.

- Always talk to a PCB supplier before you choose. This helps you get the best PCB for your project.

Overview of Semi-flex and Rigid-flex PCBs

What is a Semi-flex PCB

Sometimes, you need a circuit board that bends a little. Semi-flex PCBs are good for this. Makers thin out parts of a rigid board. This makes the board bend in certain spots. The board will not break when you bend it there. You use semi-flex PCBs in devices with tight spaces. You only bend them when you put them in or fix them. These boards do not like being bent over and over. But they give your design some flexibility in an easy way.

Tip: Semi-flex PCBs let you save space and use fewer connectors in your device.

Here is a simple table showing how semi-flex and rigid-flex PCBs are built:

| PCB Type | Structural Characteristics |

|---|---|

| Rigid-Flex | Has hard parts for mounting and flexible parts to connect areas. |

| Semi-Flex | Made by thinning hard boards so they can bend a little. |

What is a Rigid-flex PCB

Sometimes, you need more bending in your design. Rigid-flex PCBs have both hard and bendy parts. These boards use layers of hard and flexible stuff. You can put parts on the hard areas. The bendy parts connect different sections. You can fold or twist these boards many times. They do not break easily. Rigid-flex PCBs are used in things that move or change shape. Some examples are cameras, medical tools, or wearable tech.

Rigid-flex PCBs are very reliable and can fit tricky shapes, so they are great for advanced electronics.

Structure and Materials

Layer Composition

It is important to know how layers are stacked in both semi-flex and rigid-flex PCBs. Semi-flex PCBs have one hard base. The maker makes some spots thinner. These thin spots can bend, but the rest stays stiff. Most semi-flex PCBs have only one or two layers. They are good for simple circuits that need a little bend when you put them in.

Rigid-flex PCBs are built in a more complicated way. They have layers that are hard and layers that are flexible. The flexible layers go through the whole board. These layers connect the hard parts together. You can fold or twist these boards in many ways. You can add more layers to make a multi-layer flex rigid pcb. This helps with advanced circuits and lets you fit more connections. You get better signals and more ways to design with this kind of board.

Material Choices

You have to pick the right materials for your PCB. This choice changes how well your board bends and how long it lasts. Most semi-flex and rigid-flex PCBs use polyimide for the base. Polyimide bends easily and does not get damaged by heat. Some boards use polyethylene naphthalate (PEN) or aramid for special jobs. PEN bends a little, and aramid is very strong but costs more.

Here is a table that shows what different materials do:

| Material Type | Flexibility Impact | Reliability Impact |

|---|---|---|

| Polyimide | High adaptability and flexibility | Good durability under bending conditions |

| Polyethylene Naphthalate (PEN) | Moderate flexibility | Moderate reliability |

| Polytetrafluoroethylene (PTFE) | Low flexibility | High chemical resistance, moderate reliability |

| Aramid | High flexibility | Good durability but can be expensive |

You also need to think about copper thickness and surface finishes. Thin copper bends more easily. Most boards use 17μm or 35μm copper. For the finish, you often see chemical silver or ENIG. These finishes keep the copper safe and help with soldering. Soldermask or coverlay gives extra protection, especially in a multi-layer flex rigid pcb.

Tip: Pick your material based on what you need. If you bend the board a lot, use polyimide and a multi-layer flex rigid pcb for the best results.

Multi-layer Flex Rigid PCB Variants

There are many choices for multi-layer flex rigid pcb designs. These boards mix several hard and flexible layers together. You can send signals across different layers and use fewer connectors. This saves space and makes your device lighter.

A normal multi-layer flex rigid pcb uses Kapton for the base. The base can be 25 to 300 micrometers thick. Copper layers are usually 17μm or 35μm. For the finish, you can pick chemical silver or ENIG. Coverlay works as the soldermask and protects the bendy parts.

Here is a quick table of the main materials:

| Material Type | Characteristics |

|---|---|

| Base Material | Kapton |

| Thickness of Base Material | 25, 50, 125, 300 μm |

| Base Copper (Outer Layer) | 17μm / ½ oz - 35 μm / 1 oz |

| Base Copper (Inner Layer) | 17μm / ½ oz - 35 μm / 1 oz |

| Surface Finish | Chemical silver (AG); selective Ni/Au (ENIG) |

| Soldermask | Specific coverlay |

Multi-layer flex rigid pcb boards give you more ways to design and make your device strong. You can fit them into small spaces and connect lots of circuits without extra wires. This makes them great for advanced electronics, medical tools, and aerospace systems.

Flexibility and Durability

Flexing Capabilities

You want your circuit board to bend without breaking. Semi-flex PCBs let you bend them only during installation or repair. You should not flex them often. These boards work best in tight spaces where you need a little movement. Rigid-flex PCBs give you more freedom. You can fold or twist them many times. They handle dynamic movement better than semi-flex PCBs.

When you use rigid-flex PCBs in devices that move a lot, you need to think about how much they can bend. Here are some important points:

- Repeated bending can make the copper brittle and cause cracks.

- You should keep the bend angle under 90° to help the board last longer.

- The inside of the bend becomes the neutral axis, so most designs use only one copper layer in the flexible part.

Note: If you need a board that bends often, pick rigid-flex PCBs. They are built for dynamic use and last longer under stress.

Durability and Reliability

You want your electronics to work for a long time. Semi-flex PCBs are strong if you only bend them once or twice. They do not handle repeated movement well. If you bend them too much, the thin parts can crack or break. Rigid-flex PCBs are more reliable for devices that move or change shape. They use tough materials like polyimide, which resists heat and stress.

Here is a quick table to show how each type stands up to wear and tear:

| PCB Type | Best Use Case | Durability Under Stress | Reliability Over Time |

|---|---|---|---|

| Semi-flex | Occasional bending | Low | Moderate |

| Rigid-flex | Frequent movement | High | High |

If you need a board for a wearable device or medical tool, rigid-flex PCBs give you better durability and reliability.

Manufacturing Process Comparison

Semi-flex PCB Manufacturing

Making semi-flex PCBs is not hard. Makers start with a normal rigid board. They make some spots thinner so they can bend. You do not need special materials or fancy steps. Most boards use regular FR-4 material. Makers use milling or lasers to thin the bending areas. Then, they add copper lines and a cover to protect them.

Semi-flex PCBs are made faster than other types. They cost less because there are fewer steps. You use simple materials. There are not many problems with quality. But you still need to check the thin spots. These checks help find cracks or weak places before using the board.

Tip: Always ask for extra checks in the bendy spots. This helps you avoid problems later.

Rigid-flex PCB Manufacturing

Making rigid-flex PCBs is more difficult. Makers put hard and bendy layers together in one board. They use polyimide for the bendy parts and FR-4 for the hard parts. The process has steps like lamination, drilling, and plating. Each layer must line up just right. Makers add coverlay to keep the bendy parts safe.

This process takes more time and costs more money. You need special machines and skilled workers. Checks are very important at every step. You look for layer problems, copper cracks, and peeling. You also check solder spots and the finish. These boards need more checks because mistakes can cause big problems.

| PCB Type | Manufacturing Complexity | Typical Inspection Points | Cost Level |

|---|---|---|---|

| Semi-flex | Simple | Flex zones, copper traces | Low |

| Rigid-flex | Advanced | Layer alignment, coverlay, solder | High |

Note: Plan for extra checks and tests if you want strong rigid-flex PCBs.

Cost and Value

Production and Material Costs

You want to know how much these boards cost before you start your project. Semi-flex PCBs usually cost less. You use standard FR-4 material, and the process is simple. You thin out certain areas, so you do not need special machines or extra steps. This saves you money on both materials and labor.

Rigid-flex PCBs cost more. You need advanced materials like polyimide and extra layers. The manufacturing process takes longer and needs skilled workers. You pay for lamination, drilling, and careful inspections. These steps add to the price.

Here is a quick table to help you compare:

| PCB Type | Material Cost | Manufacturing Cost | Typical Total Cost |

|---|---|---|---|

| Semi-flex | Low | Low | Budget-friendly |

| Rigid-flex | High | High | Premium |

Tip: If your design needs only a little bending, you can save money with semi-flex PCBs.

Long-term Value

You should think about more than just the upfront cost. Rigid-flex PCBs give you better value over time. These boards last longer and handle more stress. You do not need to replace them often. You also save on connectors and cables because the board bends and connects different parts by itself.

Semi-flex PCBs work well for simple jobs. You use them in devices that do not move much. If you need to bend the board only once, you get good value for your money. If your device moves a lot, rigid-flex PCBs help you avoid repairs and downtime.

Consider these points when you choose:

- Rigid-flex PCBs reduce maintenance costs.

- You get more reliability in harsh environments.

- Semi-flex PCBs fit basic needs at a lower price.

When you plan your project, look at both the short-term and long-term costs. The right choice helps you save money and avoid problems later.

Application Scenarios

When to Use Semi-flex PCBs

Pick semi-flex PCBs if your device needs a little bend when you put it together. These boards fit best in small gadgets with not much space, like tiny wearables or airplane systems. You can bend them once or twice and they will not break. If your device does not move a lot, semi-flex PCBs save money and make building easier. You see these boards in small electronics and some space-saving airplane tools where you do not need much bending.

Tip: Semi-flex PCBs let you use fewer connectors and keep your device light.

When to Use Rigid-flex PCBs

Choose rigid-flex PCBs if your project needs both bending and strength. These boards can bend and twist many times, so they are good for medical tools, car dashboards, and airplane controls. You get hard spots for parts and bendy spots for links. Rigid-flex PCBs work well in places with shaking, heat, or little room. They help with cool features in smart wearables, small electronics, and important systems.

Here is a table that shows how rigid-flex PCBs work in wearable tech:

| PCB Type | Characteristics | Applications |

|---|---|---|

| Rigid-Flex | Has hard spots for parts and bendy links | Medical tools, small electronics |

| Semi-Flex | Bends a little by making hard boards thinner | Airplane systems, wearables, small gadgets |

Note: Rigid-flex PCBs give you more ways to design and make your device strong if it moves or changes shape.

Industry Examples

You find rigid-flex PCBs in lots of jobs. Medical tools use them in heart sensors, MRI machines, and medicine pumps. Car makers use these boards for connectors and screens that shake a lot. Airplane builders use rigid-flex PCBs for small, light parts in planes and rockets.

| Aspect | Automotive Applications | Aerospace Applications |

|---|---|---|

| Vibration Resistance | Handles lots of shaking from roads | Handles shaking during flights |

| Weight Considerations | Less weight helps cars | Very low weight is important for planes |

| Space Constraints | Fits in small dashboards and panels | Fits in tiny spaces inside planes |

| PCB Type | Rigid-flex and flexible PCBs for connectors | Rigid-flex and flexible PCBs for links |

You also see rigid-flex PCBs in cleaning machines and special circuits for MRI. If you want to use solar batteries, you can use these boards for longer life and better power. Many people trust the BESTFPC brand for good boards and help. You can check their website for more info and tips.

Pro tip: Rigid-flex PCBs help you make smarter, smaller, and tougher devices for any job.

Choosing the Right PCB Type

Decision Factors

You need to look at several things before you pick a PCB type. Start by checking how much your board needs to bend. If your design only bends once during installation, semi-flex PCBs work well. If your device moves a lot, rigid-flex PCBs give you better results. Think about your budget. Semi-flex PCBs cost less, but rigid-flex PCBs last longer. You should also look at the space inside your device. Rigid-flex PCBs fit into tight spots and odd shapes.

Here is a quick checklist to help you decide:

- How often does the board need to bend?

- What is your budget for materials and manufacturing?

- Does your device need to be lightweight or fit into a small space?

- Do you need high reliability for harsh environments?

Tip: Always talk to your PCB supplier about your needs. They can help you pick the best option.

Application Suitability

You want your PCB to match your project. Semi-flex PCBs work best in simple gadgets, like small wearables or basic airplane systems. These boards handle light bending and save money. Rigid-flex PCBs suit advanced electronics, medical tools, and car dashboards. You get strong boards that handle shaking, heat, and tight spaces.

| PCB Type | Best For | Not Ideal For |

|---|---|---|

| Semi-flex | Simple, static devices | Devices with frequent motion |

| Rigid-flex | Dynamic, complex electronics | Projects with low budgets |

Note: If your device faces lots of movement or stress, rigid-flex PCBs offer more safety and reliability.

Future Trends

You will see more devices using rigid-flex PCBs as technology grows. Wearable tech, medical sensors, and smart cars need boards that bend and last. Makers now use new materials and better designs to make PCBs stronger and lighter. You may find flexible circuits in foldable phones and tiny robots soon.

- Flexible electronics will get smaller and smarter.

- New materials will make PCBs last longer.

- More industries will use rigid-flex PCBs for tough jobs.

2025-12-16

2025-12-16

BEST

BEST

.png)

.png)

.png)

.png)

.png)