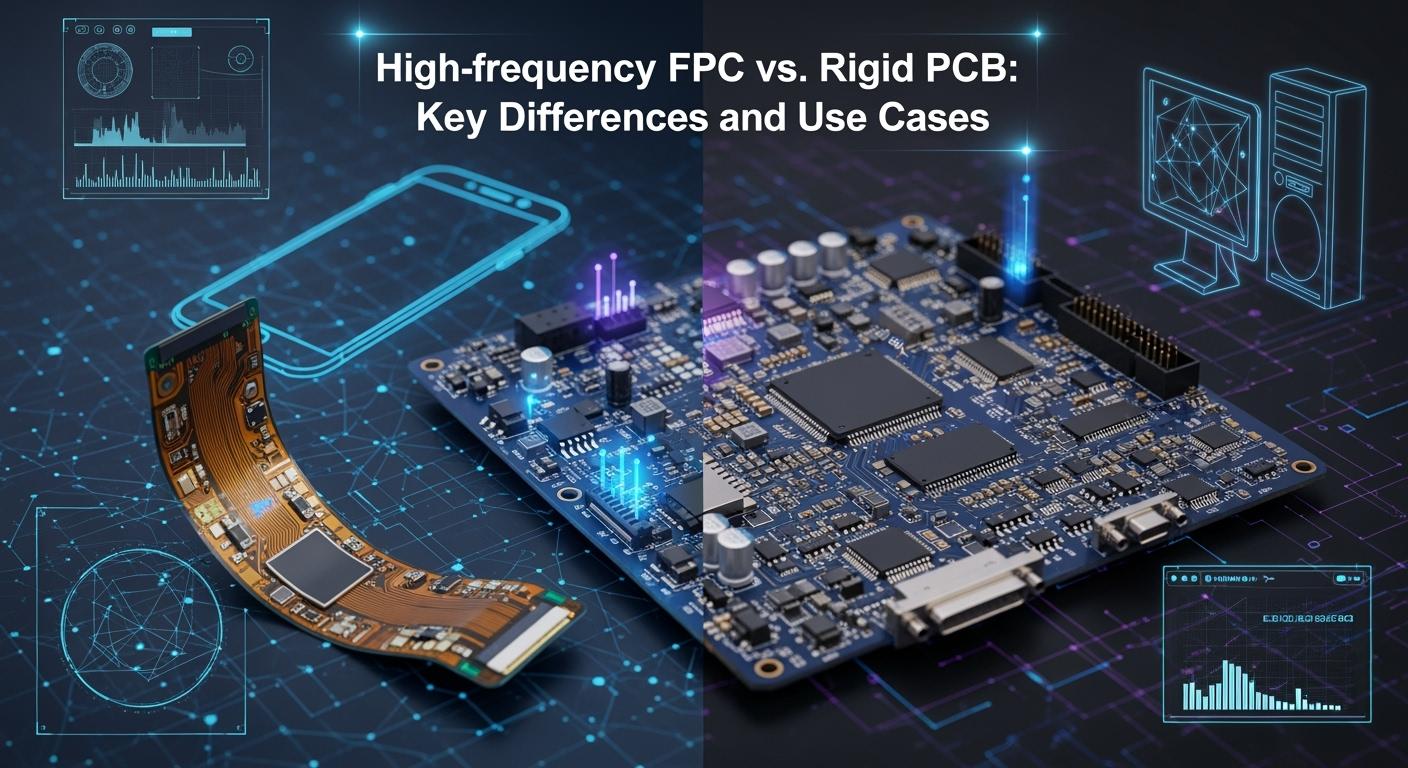

You need to pick between high-frequency FPC and rigid PCB. Think about flexibility, how well it works, and the price. High-frequency FPC saves space and is strong when bent. It also handles heat well. This makes it great for foldable smartphones, smartwatches, and medical devices. New data shows many electronics use FPCs:

-

Over 78% of foldable smartphones use advanced FPCs

-

69% of smartwatches rely on FPCs

-

58% of automotive infotainment systems feature flexible circuits

Choosing the right PCB type helps your device work well and last long.

Key Takeaways

-

High-frequency FPCs can bend and twist. They work well in small devices. These devices move a lot, like smartphones and wearables.

-

Rigid PCBs are hard and do not bend. They are good for things that stay still. Examples are computers and TVs.

-

FPCs cost more for each piece. But they save money when you put them together. They also save space. Rigid PCBs cost less when you make many at once.

-

Pick FPCs for high-frequency jobs. This is important when signals must stay strong. Pick rigid PCBs for steady work in fixed places.

-

Think about what your project needs. You should look at flexibility, price, and how long it lasts. This helps you choose the best PCB type.

Key Differences: FPC vs. Rigid PCB

Quick Comparison Table

You need to know how high-frequency FPC and rigid PCB are different. The table below helps you see the main points:

|

Feature |

High-Frequency FPC |

Rigid PCB |

|---|---|---|

|

Flexibility |

Can bend, fold, and twist |

Not flexible |

|

Performance |

Good for moving, high-frequency uses |

Works best in fixed layouts |

|

Cost |

Costs more for each piece, but saves money later |

Cheaper for each piece, good for big batches |

|

Durability |

Very strong when bent or moved a lot |

Okay strength in places that do not move |

|

Materials |

Rogers laminates help signals stay strong |

FR4 does not work as well at high speeds |

|

Design Complexity |

Harder to design because it bends |

Easier to design, but needs careful planning |

|

Use Cases |

Used in smartphones, wearables, medical, aerospace |

Used in computers, TVs, appliances |

Tip: Pick high-frequency FPC if your design needs to bend, save space, or move often. Rigid PCB is better for products that stay still and need to be cheap.

Summary of Main Differences

When you look at fpc vs. rigid pcb, you notice some big differences that matter for your design:

-

Flexibility: FPCs can bend, fold, and twist. Rigid PCBs stay flat and cannot bend.

-

Performance: FPCs are great for moving and high-frequency jobs. Rigid PCBs work best in places that do not change.

-

Cost: FPCs cost more for each piece, but you save money on putting things together and using less space. Rigid PCBs are cheaper for each piece, so they are good for making lots of products.

-

Durability: FPCs last longer in things that move or bend a lot. Rigid PCBs are strong enough for things that do not move.

-

Materials: High-frequency FPCs use special laminates like Rogers to keep signals clear. Rigid PCBs use FR4, which is not as good for fast signals.

-

Design Complexity: FPCs are harder to design because they bend. Rigid PCBs are easier, but you must plan the lines for signals well.

-

Use Cases: You see FPCs in smartphones, medical tools, and airplanes. Rigid PCBs are found in computers, TVs, and home machines.

Choose FPCs for new, small, or moving designs. Rigid PCBs are best for steady, cheap products made in large numbers. Knowing these differences helps you pick the right PCB for your project.

What is High-frequency FPC(Flex Print PCB)?

Structure and Materials

High-frequency FPC uses special materials to work well in tough places. The main materials are polyimide, liquid crystal polymer (LCP), and PTFE-based substrates. Each one helps the FPC in a different way. Polyimide gives strength and can handle heat. LCP keeps its shape and works well with electricity. PTFE-based substrates have low dielectric constants and can handle heat too. These materials help signals stay clear, especially when used for high-frequency jobs.

|

Material |

Key Properties |

Impact on Electrical Performance |

|---|---|---|

|

Polyimide |

Strong, handles heat, resists chemicals |

Good for tough places; stays strong when bent |

|

Liquid Crystal Polymer (LCP) |

Keeps its shape, works well with electricity |

Great for fast and high-frequency uses |

|

PTFE-based substrates |

Low dielectric constants, low loss, handles heat well |

Keeps signals clear in fast circuits; works in rough places |

Features and Benefits

Picking an FPC flexible PCB gives your device many good features. High-frequency FPC uses special laminates and materials that lose less signal. This helps send data very fast. Fine-pitch traces let you fit more things in a small space. Multi-layer stacking lets you make hard circuits without making them bigger. Laser direct structuring (LDS) helps make lots of FPCs that are the same. EMI shielding films and ground layers cut down on interference. Heat spreaders help control heat in small devices. These features make high-frequency FPC a smart pick for high-frequency PCB needs.

|

Feature/Benefit |

Description |

|---|---|

|

High-frequency laminates |

Needed for sending signals very fast in advanced systems. |

|

Low-loss dielectric materials |

Cuts down signal loss, helps in fast jobs. |

|

Fine-pitch traces |

Lets you send more data and add more functions in small designs. |

|

Multi-layer stacking |

Helps make hard circuits fit in small spaces. |

|

Laser direct structuring (LDS) |

Makes it easier to build lots of FPCs with fewer mistakes. |

|

EMI shielding films |

Stops signals from mixing and getting weaker, important for fast jobs. |

|

Embedded ground layers |

Keeps signals strong by stopping interference. |

|

Integration with modular antenna arrays |

Helps manage signals in telecom devices. |

|

Embedded heat spreaders |

Helps get rid of heat in small hardware. |

|

High reliability and bandwidth efficiency |

Makes FPCs important parts in communication systems. |

Note: High-frequency FPCs are very reliable and work fast, so they are needed in modern electronics.

Typical Applications

High-frequency FPC is used in many areas. In cars, it is found in engine controls, sensors, lights, and entertainment systems. Medical devices use FPC flexible PCB in hearing aids, imaging tools, and wearable monitors. Factories use these circuits for robots, automation, VR headsets, and IoT devices. These examples show how high-frequency FPC helps new technology in many fields.

|

Industry |

Application Examples |

|---|---|

|

Automotive |

Engine controls, sensors, lights, entertainment systems |

|

Medical |

Hearing aids, imaging tools, wearable monitors |

|

Industrial |

Robots, automation, VR headsets, IoT devices |

Rigid PCB Overview

Structure and Materials

Rigid pcb is used in most electronics. Makers use strong materials for these boards. The main material is FR-4. FR-4 is made from fiberglass cloth and epoxy resin. This mix gives good insulation and stops fire. It also makes the board strong. Copper is used for the traces. Copper helps signals move and makes the board last longer.

|

Material |

Composition |

Key Properties |

|---|---|---|

|

FR-4 |

Fiberglass cloth + Epoxy resin |

Electrical insulation, flame-retardant, mechanical strength |

|

Copper |

Conductive traces |

Electrical conductivity, reliability, durability |

Rigid pcbs have great electrical and thermal properties. They are strong and resist chemicals. These materials are easy to find and work for many designs. Makers use them because they save money and work well.

Features and Benefits

Rigid pcb technology has many good points. It is cheap to make because the process is simple. These boards can have many layers. This lets you fit more circuits in less space. The layout helps lower electronic noise. This makes signals better. Rigid pcbs do not break easily from shaking or stress. They protect the parts inside. It is easy to fix and check these boards. You can see the traces and marks quickly.

-

Cheap for making lots of boards

-

Many layers for more circuits

-

Less noise for better signals

-

Strong against shaking and stress

-

Easy to fix and check

-

Does not bend or warp easily

-

Gets rid of heat well

-

Used in many types of devices

Tip: Rigid pcbs help devices work well and stay strong. They are best for things that need solid boards and good performance.

Common Applications

Rigid pcb is found in many things you use. They are in TVs, home gadgets, computers, and phones. Network tools and base stations use rigid pcbs for good connections. Cars use them in control units and sensors. Medical tools like heart monitors and MRI machines need rigid pcbs for correct results. Defense and space tech use these boards in navigation and military gear.

-

Laptops and desktop computers

-

Audio keyboards and solid-state drives

-

Flat-screen TVs and monitors

-

Children’s toys and gadgets

Rigid pcbs are the top pick for engineers. They are strong, reliable, and save money. You see them in almost every field, from home electronics to space systems.

FPC Flexible PCB: Performance and Reliability

Signal Integrity and Frequency Handling

Good signal integrity is important for fast signals in electronics. FPC uses special materials that keep signals strong. It controls impedance very well. FPC works in microwave and gigahertz frequency jobs. Signal stability is very important in these uses. The table below shows how fpc and rigid PCB compare for signal performance:

|

Feature |

High-Frequency FPCs |

Rigid PCBs |

|---|---|---|

|

Signal Type |

Analog high-frequency signals |

High-speed digital signals |

|

Frequency Range |

Microwave and gigahertz frequencies |

Limited high-speed capabilities |

|

Impedance Control |

Requires controlled impedance |

Less focus on impedance |

|

Material Loss |

Low-loss materials like Rogers RO4000 |

Higher loss materials like FR-4 |

|

Shielding |

Requires shielding to prevent interference |

Less emphasis on shielding |

|

Parasitic Management |

Careful management of parasitics |

Not typically addressed |

|

Applications |

RF circuits, radars, satellites, 5G |

General electronic applications |

FPC sends fast signals with strong connections. It is the best choice for RF circuits and 5G devices. You get steady performance and less interference.

Flexibility and Space Efficiency

FPC can bend, fold, and wrap around parts. You do not need big connectors or wires. This helps you make smaller and lighter devices. FPC lets you use space better in smartphones, wearables, and drones. You can make compact designs and still keep good performance.

-

FPC lets you put parts closer together.

-

You can fold or wrap fpc around parts.

-

Devices get lighter and smaller.

-

Saving space helps devices work better.

You have more room for new features. You keep fast signals even in small spaces.

Heat Dissipation

Good heat control is needed in strong electronics. FPC uses polyimide materials for better heat control and strength. Flexible printed circuits get rid of heat better than rigid PCBs. You do not need mechanical connectors, so devices work better in tough places.

-

Polyimide flex materials help with heat.

-

FPC gets rid of heat very well.

-

Devices last longer and work better under stress.

Your electronics stay cool and keep strong signals, even when used a lot.

Rigid PCB: Power and Durability

Current and Voltage Handling

Rigid PCBs are used when you need strong power. These boards have thick copper layers. Thick copper helps carry more current. It does not get too hot. You see this in power supplies and car electronics. Rigid PCBs spread voltage across many layers. This keeps power steady for all parts. The solid board stops voltage drops and noise. Devices work well when they need steady power.

|

Feature |

Benefit for Your Design |

|---|---|

|

Thick copper layers |

Handles high current loads |

|

Multi-layer structure |

Distributes voltage evenly |

|

Stable connections |

Reduces electrical noise |

Tip: Use rigid PCBs for devices that need lots of power. Good examples are servers, motor controllers, and base stations.

Mechanical Strength

Rigid PCBs make devices strong. They help when things shake or get bumped. The fiberglass and epoxy resin base is tough. It does not bend or break easily. Rigid PCBs are better than flexible PCBs in rough places. They keep their shape under stress. You see this in medical tools and car systems. Rigid-flex PCBs mix both types for extra strength. They help protect important parts and keep things working.

-

Rigid PCBs do not bend or crack.

-

They work better in tough places.

-

Rigid-flex PCBs give more support for important jobs.

Insulation and Reliability

Rigid PCBs give great insulation. FR-4 material blocks unwanted currents. It stops short circuits. Your circuits stay safe from water and dust. Rigid PCBs keep their shape for a long time. This lowers the chance of problems. Your device lasts longer. The strong board helps in important systems. You can trust rigid PCBs in medical and space tools.

Note: Rigid PCBs have strong insulation and last a long time. They help make electronics safe and tough.

FPC vs. Rigid PCB: Cost and Manufacturing

Cost Factors

When you look at high-frequency FPC and rigid PCB, cost is important. Many things change how much each board costs. You have to think about what materials you use. The design can be simple or hard, and that changes the price. The size of your circuit also matters. The table below shows what affects the cost:

|

Cost Factor |

Description |

|---|---|

|

Material Selection |

Picking different materials changes the price a lot. Some are cheap, but others like LCP cost more. |

|

Manufacturing Complexity |

FPCs need harder steps to make because their designs are tricky. |

|

Layer Count |

More layers in FPCs make them harder and more expensive to build. |

|

Processing Requirements |

FPCs need special steps, so they cost more than rigid PCBs. |

|

Circuit Size |

Bigger circuits use more stuff, so they cost more. |

|

Circuit Shape |

Odd shapes waste material, which makes the price go up. |

|

Via Type |

Blind and buried vias are harder to make and cost more. |

|

Feature Size |

Smaller features need better tools, so it is harder to make. |

Tip: You can save money by picking easy designs and normal materials. Always pick the right board for your project to get the best deal.

Manufacturing Processes

There are big differences in how FPC and rigid PCB are made. High-frequency FPCs use special materials like polyimide. Polyimide can cost much more than FR4, which is used in rigid PCBs. FPC materials are easy to break, so workers must be careful. This can mean more mistakes and higher prices. Rigid PCBs use normal materials and steps, so they are easier to make in big numbers. This helps lower the price when you need a lot of boards.

FPCs are picked for new devices that need to bend and work fast. Rigid PCBs are good when you want strong boards for lots of products and want to save money. Think about what your project needs before you choose which one to use.

Pros and Cons: High-frequency FPC and Rigid PCB

High-frequency FPC: Pros and Cons

High-frequency FPC gives your design many good things. You can save space because FPCs fit in small places. They help your device send and get data with less loss. FPCs last longer when you bend or move them a lot. You can shape them in many ways, so your design stays flexible.

But you need to be careful with FPCs. They might break if you bend them too much when putting them together. FPCs do not carry as much power as rigid PCBs. Fixing or changing FPCs costs more money. FPCs can also have problems with water or chemicals around them.

|

Advantages |

Limitations |

|---|---|

|

Space-saving |

Sensitivity to handling |

|

High signal integrity |

Limited power capacity |

|

Durability |

Cost of rework |

|

Design flexibility |

Environmental vulnerability |

Tip: Use high-frequency FPC if your device needs to be small, bendable, and work well with fast signals.

Rigid PCB: Pros and Cons

Rigid PCBs are strong and steady for many uses. You can make lots of them fast, which saves money. These boards work well for a long time. You can control impedance easily, so signals stay clear. Rigid PCBs keep dielectric properties the same, so your device works right every time.

You cannot bend rigid PCBs. They do not fit well in wearables or odd-shaped places. If your device shakes or vibrates, rigid PCBs might crack or break. Connectors on these boards can snap if stressed.

|

Pros |

Cons |

|---|---|

|

High manufacturing efficiency |

Limited flexibility |

|

Cost-effective for mass production |

Unsuitable for wearable technology |

|

Reliable and durable for long-term use |

Prone to mechanical failures in vibrations |

|

Ideal for controlling impedance |

Inability to adapt to complex geometries |

|

Consistent dielectric properties |

Connectors may break under mechanical stress |

Note: Pick rigid PCB for devices that need strong boards, steady work, and low cost for big batches.

Application Scenarios

Consumer Electronics

You find high-frequency FPCs and rigid PCBs in many small gadgets. Flexible circuits let you add more features to tiny devices. For example, battery management systems in electric cars like the Tesla Model Y use FPCs. These FPCs connect battery cells and send data fast. In fancy cars, advanced PCBs control smart headlights. FPCs power bendable light strips. In small electric cars like the Nissan Leaf, FPCs join power window controls, door locks, and speakers in one unit. This saves space and makes fixing things easier.

-

FPCs help make thinner smartphones and smartwatches.

-

Rigid PCBs give strength to laptops and TVs.

-

Flexible circuits make wiring easier in smart home gadgets.

Tip: You can make smaller and lighter products by picking the best PCB for your design.

Automotive and Aerospace

You need both FPCs and rigid PCBs for safety and good work in cars and planes. Car control units use rigid PCBs for engines and entertainment systems. FPCs link sensors and lights in tight spots. Self-driving cars use many sensors, and flexible circuits help fit them in small spaces. Special shielding stops interference. Strong materials handle heat, cold, and shaking.

|

Sector |

Use Cases |

|---|---|

|

Automotive |

Instrument clusters, steering wheel controls, airbag sensors, seat occupancy systems, rearview cameras, infotainment touchscreens, engine control modules, LED lighting systems, EV battery management, radar and LiDAR sensors, HVAC control units, smart mirrors, interior ambient lighting |

|

Aerospace |

Avionics displays, satellite modules, navigation and radar systems, flight control electronics, space sensors, UAV wiring systems, cockpit panels, military communications, missile guidance circuits, environmental instrumentation |

-

Flexible PCBs fit well in odd shapes and tight places.

-

Rigid PCBs give steady support for flight control and navigation.

Medical Devices

You count on high-frequency FPCs and rigid PCBs to keep medical tools working well. Flexible circuits can bend over 100,000 times, which is important for wearable medical devices. Special materials like PTFE-based laminates keep signals strong in high-frequency jobs. Makers follow strict ISO 10993 rules for safety and strength. Making things smaller lets you build portable monitors and hearing aids. Hybrid connectors send both power and data.

|

Future Trend / Innovation |

Description |

|---|---|

|

Miniaturisation |

Smaller connectors for portable devices |

|

High-Speed Data Transmission |

Over 10Gb/s with strong shielding |

|

Rugged Durability |

Better shock and vibration resistance |

|

Simplified Assembly |

Tool-free connectors for robot installation |

|

Hybrid Connectors |

Send signal and power together |

Note: You can trust flexible PCBs for important medical jobs because they last long and keep signals clear.

Industrial Equipment

You use FPCs and rigid PCBs in factory robots, automation, and testing machines. Flexible circuits work well with moving parts and tight spaces. Rigid PCBs give strength to control panels and big machines. You test how well circuits carry electricity and block it. Mechanical tests check how many times they can bend and how tough they are. Environmental tests see how circuits handle changes in temperature, humidity, and salt spray.

2025-12-15

2025-12-15

BEST

BEST

.png)

.png)

.png)

.png)

.png)