When I first explored fpc engineering, I realized how essential flexible circuits are for modern devices. These components allow engineers to design electronics that bend, fold, and fit into tight spaces. Flexible circuits power smartphones, medical devices, and wearables. I believe anyone can start learning about these components with the right guidance. BESTFPC shares practical insights from real projects, making complex ideas easier to grasp.

Key Takeaways

- Flexible printed circuits (FPCs) enable electronics to bend, fold, and fit into tight spaces, making devices slimmer and more durable.

- Key FPC components include flexible substrates, copper traces, coverlays, adhesives, stiffeners, and shielding, each playing a vital role in performance and protection.

- Choosing the right materials and components improves reliability, reduces weight, and ensures circuits withstand repeated bending and harsh environments.

- Precise assembly techniques like ACF bonding, solder paste application, and microsoldering are essential for building strong, high-quality flexible circuits.

- Beginners should handle FPCs carefully, use proper tools, learn design software, and troubleshoot methodically to create successful flexible circuit projects.

FPC Engineering

What Is FPC Engineering?

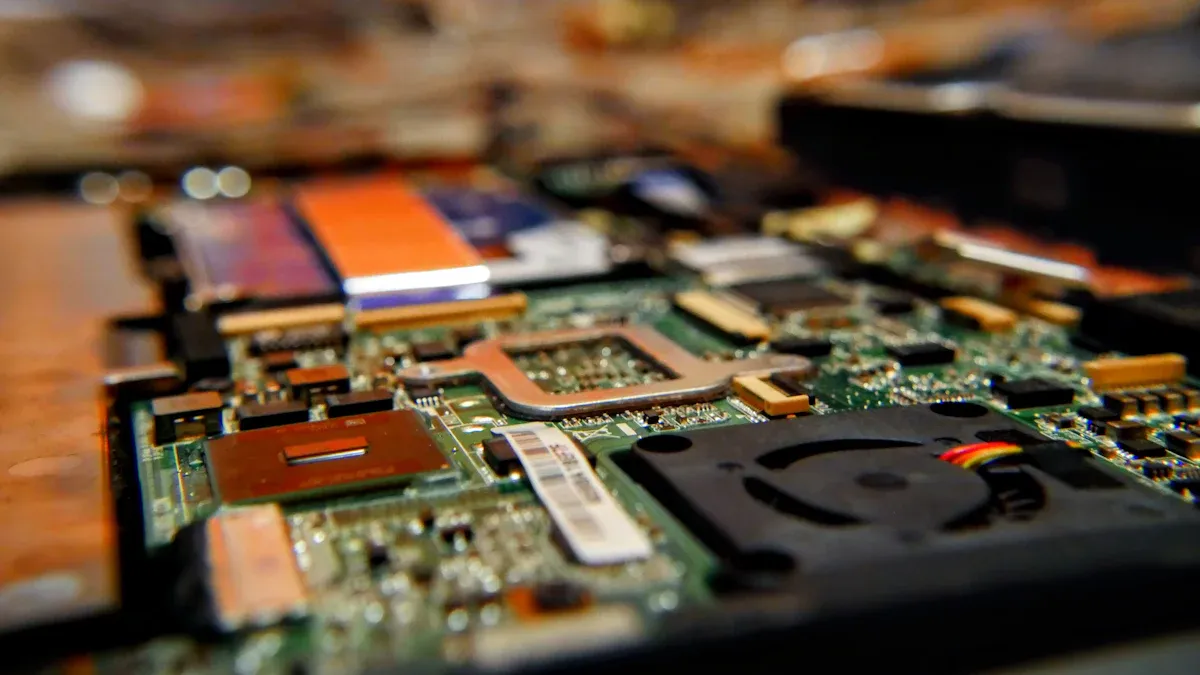

When I first encountered fpc engineering, I saw how it transformed the electronics industry. This field focuses on designing, prototyping, and manufacturing flexible circuit boards that adapt to various shapes and spaces. Engineers select materials like adhesiveless substrates and copper conductors to ensure circuits perform reliably in dynamic environments. I often use fpc engineering to optimize product development, from concept to delivery. The process involves system integration, prototyping, validation, and hands-on debugging. I rely on these steps to guarantee that flexible circuits meet the demands of modern devices.

Tip: Flexible circuits allow me to create electronics that bend, twist, or fold without damage. This flexibility opens new possibilities for device design.

| Role Aspect | Description |

|---|---|

| Design & Prototyping | Validating and optimizing flexible circuit boards and rigid-flex PCBs. |

| Material Selection | Choosing materials for dynamic use and reliability. |

| Manufacturing Expertise | Ensuring manufacturability and quality through specialized engineering. |

| Product Development | Supporting solutions from concept to delivery. |

| Industry Applications | Serving medical, automotive, AI, and communications sectors. |

| Challenges Addressed | Tackling environmental protection, signal integrity, and system coexistence. |

Why Need Engineering In Flexible Circuits?

I see several reasons why fpc engineering is essential. Flexible circuits save space and reduce weight, making devices slimmer and more portable. I can bend, twist, or fold these circuits, which is crucial for integrating them into curved or moving parts. Durability improves because flexible circuits withstand repeated movement without breaking. Fewer connectors mean fewer weak points and simpler assembly, which lowers the chance of failure.

- Flexible circuits enable slimmer, lighter devices.

- I can design electronics that bend and fold for unique applications.

- Reliability increases with fewer connectors and robust materials.

- Device assembly becomes easier and more efficient.

Modern electronics, especially displays, require flexibility to handle mechanical stress. Innovations like stretchable microLED screens and rollable TVs prove that flexibility is vital for performance and new device designs.

BESTFPC 15 Years Of Experience

I trust BESTFPC because of their extensive experience in fpc engineering. Over 17 years, they have delivered more than 10,000 FPC samples and served over 3,000 clients worldwide. Their factory produces up to 100,000 pieces daily, maintaining strict quality standards with certifications like UL, ISO13485, ISO9001, and RoHS. I value their ability to design and manufacture complex, high-end FPC projects, offering turnkey assembly services and in-house production. Their commitment to reliability and innovation makes them a leader in the field.

Key FPC Components

Understanding the essential components of flexible printed circuits is the foundation of fpc engineering. I always start by identifying each part and its role in the overall performance of the circuit. Here are the key components I work with in every project:

Flexible Substrates

The flexible substrate forms the backbone of any FPC. I rely on polyimide for most applications because it offers outstanding thermal stability, handling temperatures up to 260°C. This material resists tearing and cracking, thanks to its tensile strength of about 165 MPa. Polyimide’s dielectric constant, around 3.4, ensures stable signal transmission, which is critical for medical wearables and compact electronics. The substrate remains lightweight and thin—usually between 0.05 and 0.1 mm—so devices stay slim and comfortable to wear. When I select a substrate, I always consider its flexibility and ability to withstand repeated bending without failure.

Note: Polyimide substrates help me design circuits that can bend, twist, and fit into tight spaces without losing performance.

Copper Traces Of FPC

Copper traces act as the electrical highways of the circuit. I use rolled annealed copper for its flexibility and excellent conductivity. These traces carry signals and power between components. The thickness and width of the copper traces affect current capacity and signal integrity. I pay close attention to the layout to avoid signal loss or interference, especially in high-speed or sensitive applications. Proper copper trace design ensures the circuit performs reliably, even under mechanical stress.

Coverlays FPC

Coverlays protect the delicate copper traces from environmental hazards. I prefer polyimide coverlays because they combine thermal stability, flexibility, and chemical resistance. These coverlays operate in extreme temperatures, from -40°C to 150°C, and shield the circuit from abrasion, UV light, chemicals, and moisture. Adhesiveless polyimide coverlays further improve durability and flexibility, especially in high-vibration environments. I often use coverlays about 0.025 mm thick to maintain a slim profile while ensuring robust protection.

- Polyimide coverlays withstand temperatures up to 400°C.

- They resist chemicals and solvents, thanks to their molecular structure.

- The low coefficient of thermal expansion reduces stress on the circuit.

- Adhesiveless options enhance bonding and reliability.

Adhesives FPC

Adhesives bond the layers of the FPC together. I typically use FPC bonding adhesives, which are formulated specifically for flexible circuits. Acrylic adhesives are common because they provide strong, flexible bonds and perform well in humid or high-temperature environments. The adhesive layer is usually thin—about 0.025 to 0.05 mm—so it does not add bulk. I always check that the adhesive is safe for skin contact if the device will be worn, and that it maintains its properties over time.

- FPC bonding adhesives are designed for flexibility and durability.

- Acrylic adhesives offer strong bonds and resist moisture.

- The right adhesive ensures the circuit stays intact during repeated flexing.

Stiffeners FPC

Stiffeners add mechanical support to specific areas of the flexible circuit. I use them to reinforce connector regions or mounting points, preventing damage during assembly or use. Stiffeners can be made from materials like polyimide or FR-4 (a type of fiberglass). By adding stiffness only where needed, I keep the rest of the circuit flexible. This targeted support helps maintain reliability without sacrificing the benefits of a flexible design.

| Stiffener Material | Typical Use Case | Benefit |

|---|---|---|

| Polyimide | Connector support | Maintains flexibility |

| FR-4 | Component mounting area | Adds rigidity and strength |

Shielding FPC

Shielding protects the circuit from electromagnetic interference (EMI) and radio frequency interference (RFI). I often add a thin layer of conductive material, such as copper or aluminum, to block unwanted signals. Shielding is essential in environments with lots of electronic noise, like automotive or industrial settings. Proper shielding ensures the circuit transmits signals accurately and prevents malfunctions caused by external interference.

Tip: I always evaluate the need for shielding early in the design process, especially for circuits used in sensitive or high-frequency applications.

Each of these components plays a unique role in fpc engineering. By understanding their properties and functions, I can design flexible circuits that meet the demands of modern electronics—whether for wearable devices, medical sensors, or advanced industrial equipment.

Component Functions

Substrate Role

When I design a flexible printed circuit, I always start with the substrate. This layer acts as the foundation for the entire circuit. Polyimide is my preferred choice because it remains stable under high temperatures and resists tearing. The substrate keeps the circuit thin and light, which is essential for wearable devices and compact electronics. I often compare it to the flexible spine of a book—it holds everything together while allowing movement. In fpc engineering, the right substrate ensures the circuit can bend and twist without breaking.

Copper Trace Function

Copper traces form the electrical pathways on the substrate. I think of them as the roads that connect different parts of a city. These traces carry signals and power between components. The width and thickness of each trace determine how much current it can handle. In my experience, rolled annealed copper works best for flexibility and conductivity. When I lay out copper traces, I make sure they avoid sharp bends, which can cause cracks over time. Good copper trace design is crucial for reliable performance in fpc engineering.

Coverlay Purpose

Coverlays serve as protective shields for the copper traces. I use polyimide or liquid photoimageable materials, usually around 0.025 mm thick, to create a barrier against moisture, dust, and mechanical stress. This layer keeps the copper from oxidizing and prevents short circuits. I have seen how coverlays preserve flexibility while protecting the circuit from sweat and humidity, especially in medical and wearable devices. The coverlay acts like a raincoat for the circuit, keeping it safe from environmental hazards and repeated bending. This protection greatly enhances the durability and reliability of the FPC.

Tip: I always pair coverlays with strong adhesives to maintain structural integrity under stress.

Adhesive Use

Adhesives play a vital role in holding the layers of the FPC together. I rely on high-temperature double coated tapes, such as the 3M Ultra High Temperature Double Coated Tape 9077, for their ability to withstand soldering processes up to 260°C. These adhesives keep the substrate, copper, and coverlay bonded, even during heat-intensive assembly. I also use them to secure heat sinks and sensitive metals. Their excellent holding power and low outgassing ensure the circuit remains reliable over time.

I use adhesives to:

- Attach flexible circuits to other surfaces.

- Bond layers during manufacturing.

- Secure components that generate heat.

- Maintain adhesion during repeated bending and flexing.

Stiffener Support

Stiffeners provide extra support where the circuit needs it most. I add them to connector areas or mounting points to prevent damage during assembly or use. Polyimide stiffeners keep the circuit flexible, while FR-4 stiffeners add rigidity for heavy components. I think of stiffeners as reinforcements—like adding a splint to a flexible arm. They help the FPC maintain its shape and protect delicate areas from mechanical stress.

| Stiffener Type | Where I Use It | Benefit |

|---|---|---|

| Polyimide | Connector regions | Flexibility + support |

| FR-4 | Mounting/component area | Rigidity + protection |

Shielding Protection

Shielding protects the circuit from electromagnetic and radio frequency interference. I add a thin layer of copper or aluminum to block unwanted signals. This step is critical in environments with lots of electronic noise, such as cars or factories. Shielding ensures the signals in the circuit remain clear and accurate. I always evaluate the need for shielding early in the design process, especially for sensitive or high-frequency applications. Proper shielding prevents malfunctions and keeps the device working as intended.

I have learned that each component in fpc engineering plays a unique role. When I combine them thoughtfully, I create flexible circuits that are reliable, durable, and ready for real-world challenges.

FPC Engineering Assembly

ACF Bonding In FPC Fabrication

When I assemble flexible circuits, I often use Anisotropic Conductive Film (ACF) bonding. This process lets me connect fine-pitch components to the FPC without bulky connectors. I place the ACF between the circuit and the component, then apply heat and pressure. The film contains tiny conductive particles that create electrical paths only where needed. This method gives me strong, reliable connections and keeps the assembly thin. I rely on ACF bonding for displays, cameras, and other compact devices where space is tight and precision matters.

Tip: I always check the bonding temperature and pressure to avoid damaging the flexible substrate.

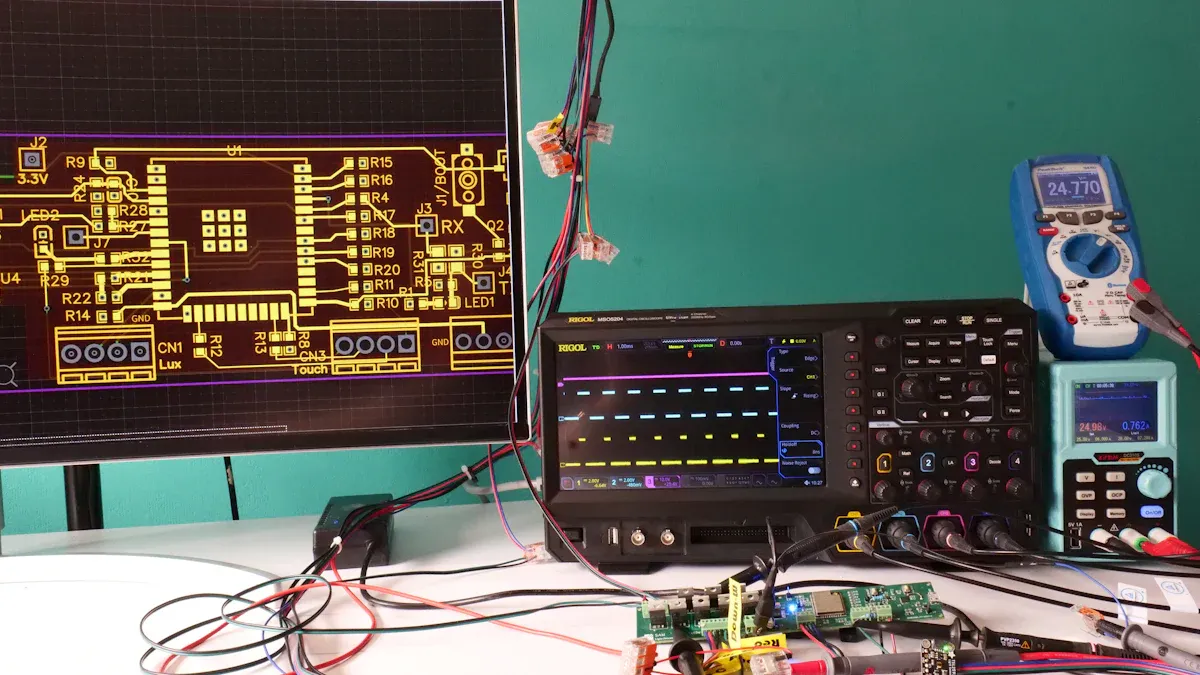

Solder Paste In FPC SMT

Surface-mount technology (SMT) is a core part of fpc engineering. I use solder paste to attach components to the FPC surface. Solder paste acts as both a mechanical and electrical bond. For fine-pitch parts, I choose Type 4 solder paste because its small particles melt evenly and reduce stress on the components. This helps me achieve precise placement, which is critical for high-density boards. Solder paste also holds parts in place before soldering, making assembly smoother.

- Type 4 solder paste offers superior precision for fine-pitch components.

- Smaller particles melt uniformly, reducing thermal and mechanical stress.

- The right solder paste improves joint strength and reliability.

- Proper stencil design and environmental control boost assembly quality.

- Good flux chemistry in solder paste helps with wetting and cleaning.

I always select solder paste carefully to ensure strong, reliable joints and high assembly yields.

Microsoldering In Flex PCBs SMT

Microsoldering is essential when I work with tiny surface-mount devices on flexible circuits. This process requires steady hands, magnification, and sub-millimeter precision. I use tools with 0.2mm tips and align components within ±0.1mm. Flex PCBs can warp or delaminate if I apply too much heat, so I work carefully to avoid damage. Unlike traditional through-hole soldering, many joints are hidden beneath chips and need X-ray inspection.

| Aspect | Microsoldering SMDs | Traditional THT Components |

|---|---|---|

| Tool Precision | 10x magnification, 0.2mm tips | Larger contacts, ~2mm tolerance |

| Alignment | ±0.1mm precision | ±1mm acceptable |

| Heat Sensitivity | Risk of delamination, warping | More heat resilient |

| Solder Joints | Often hidden, X-ray needed | Visible and accessible |

I have learned that precision equipment and careful technique are vital for reliable flex PCB assemblies. These steps help me deliver robust, high-quality products in every fpc engineering project.

Choosing FPC Components

Project Needs

When I start a new project, I always define the requirements first. I look at the device’s purpose, size, and power needs. For battery-powered devices, I select components that use less power and have high efficiency. I also consider the available space. Small package ICs and surface-mount devices help me fit everything onto a compact board. I check if the parts come from reliable manufacturers and if they are easy to source. This step helps me avoid delays and ensures I can scale production if needed.

Tip: I always balance performance with cost. Over-specifying components can increase expenses without real benefits.

- Power efficiency

- Size and form factor

- Reliability and availability

- Vendor partnership and supply chain support

Compatibility

I make sure all components work together smoothly. I match voltage levels and communication protocols, such as SPI or I2C, to prevent system issues. I always verify electrical specifications and check that each part supports the same interfaces. I partner with vendors who follow industry standards like IPC-A-610 for quality assurance. I manage the Bill of Materials (BOM) carefully, specifying alternatives and reviewing tolerances. This approach keeps my designs reliable and scalable.

- Match voltage and power requirements

- Align communication protocols

- Use industry-standard components

- Maintain a well-structured BOM

Durability

Durability matters, especially for devices in harsh environments. I select materials and designs that withstand heat, stress, and repeated bending. The table below shows key factors that influence durability and my recommendations:

| Factor | Influence on Durability | My Recommendation |

|---|---|---|

| Thermal Conductivity | Prevents overheating and failure | Use high-conductivity materials |

| Coefficient of Thermal Expansion | Reduces thermal stress and cracking | Choose materials with matching CTE |

| Delamination Resistance | Prevents layer separation | Use high Tg polyimide |

| Lead-Free Soldering Stress | Avoids warping and cracking | Select materials with high Tg |

| Design Features | Improves heat dissipation | Add thermal vias |

| Hybrid Material Designs | Balances heat resistance and flexibility | Combine metal core with polyimide |

Cost Factors

I always consider cost when choosing FPC components. Material selection plays a big role. For low-speed circuits, I might use polyester films instead of polyimide to save money. I prefer widely available, generic parts to keep the BOM cost down. I use multifunction chips to reduce the number of components. I also optimize passive components by using standard values. Power-efficient parts let me use smaller, cheaper batteries. I design for manufacturability by standardizing hole sizes and avoiding tight tolerances, which lowers production costs.

- Choose cost-effective materials

- Use generic, widely available components

- Integrate multifunction chips

- Optimize passive component selection

- Design for efficient manufacturing

By following these steps, I ensure my FPC designs meet project needs, work reliably, last longer, and stay within budget.

Beginner Tips For FPC Engineering

Handling

When I handle flexible printed circuits, I always use clean gloves. Oils and dirt from my hands can damage the delicate copper traces. I avoid bending the FPC sharply or folding it at tight angles. This prevents micro-cracks and extends the circuit’s life. I store FPCs in anti-static bags to protect them from static electricity. I also keep them flat or gently rolled to avoid creases.

Tip: Always inspect the FPC for dust or scratches before assembly. Even small particles can cause defects.

Assembly Advice

I prepare my workspace before starting assembly. I use a grounded mat and wrist strap to prevent static discharge. I organize all components and tools within easy reach. When placing components, I use tweezers with smooth tips. This helps me avoid damaging the substrate. I apply solder paste sparingly and use the correct temperature for reflow. Overheating can warp the FPC or cause delamination.

- Use precision tools for small parts.

- Double-check alignment before soldering.

- Allow the FPC to cool naturally after soldering.

Troubleshooting

If a circuit does not work, I start by checking for visible defects. I look for broken traces, cold solder joints, or lifted pads. I use a multimeter to test continuity along the copper traces. If I find a problem, I repair it with microsoldering or conductive ink. I always document each issue and solution. This helps me improve future designs.

| Problem | What I Do |

|---|---|

| Broken trace | Repair with solder/ink |

| Cold solder joint | Reheat with fine tip |

| Lifted pad | Secure with adhesive |

Design Software

I recommend learning PCB design software early. I started with easy tools like EasyEDA and moved to more advanced platforms such as Altium Designer. These programs let me draw circuit layouts, simulate signals, and check for errors before manufacturing. I also study basic electronics and mechanical design. This multidisciplinary approach helps me create better FPCs.

BESTFPC’s engineers use industry-standard software and share design files with clients. This ensures smooth communication and faster project delivery.

I have seen how understanding each part of fpc engineering helps me build better flexible circuits. With the right knowledge and a few practical tips, anyone can start working with these components. I always recommend hands-on practice to reinforce learning. If you want to explore more or need expert advice, reach out to BESTFPC. You can take the next step by trying a simple FPC project or studying advanced design guides.

2025-08-13

2025-08-13

BEST

BEST

.png)

.png)

.png)

.png)

.png)