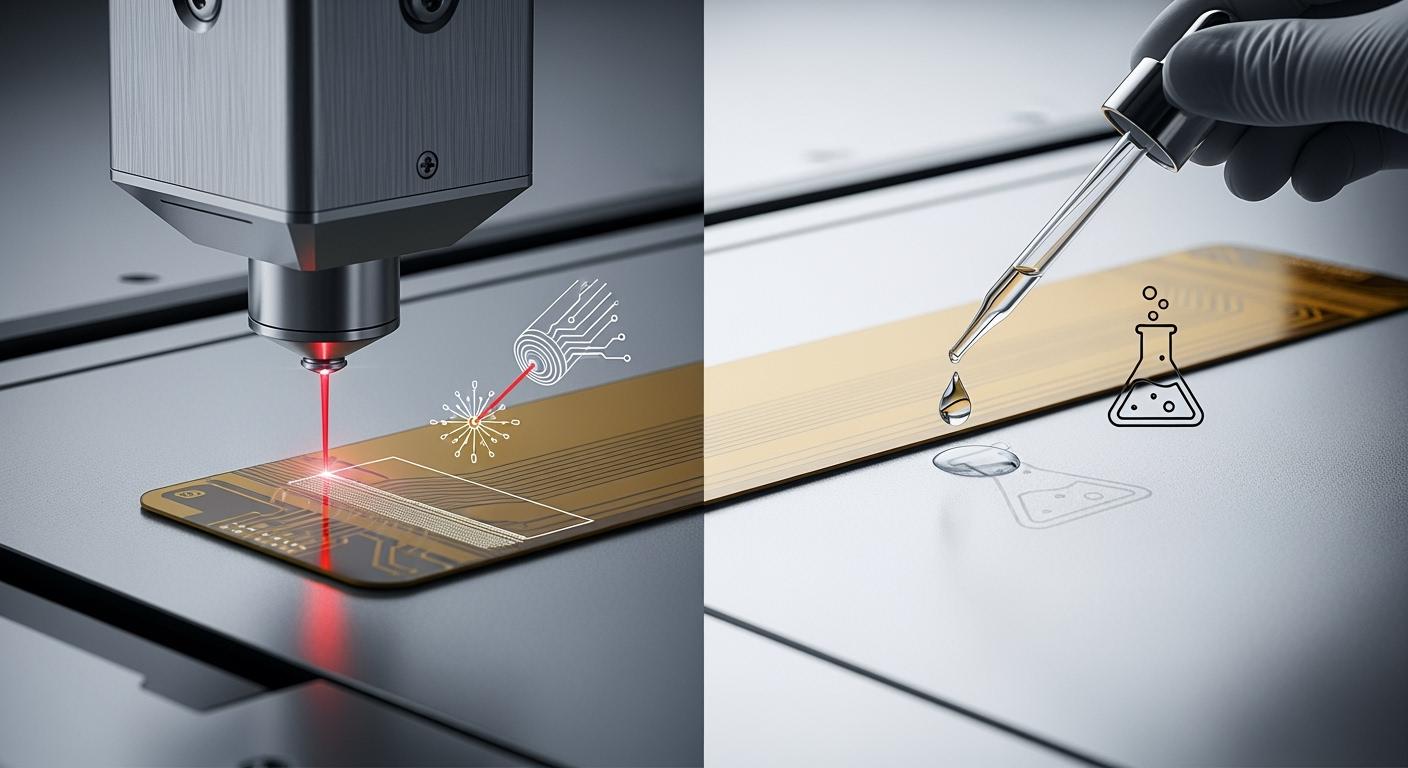

When you pick an etching process for flexible pcbs, laser technology usually gives better accuracy and quality than chemical methods. Laser techniques work very well in making flexible circuits that need to be strong and reliable during assembly. Chemical etching can be good for making many pieces at once, but laser methods let you control the etched fpc details better. What you choose will change how reliable and good your flexible design is in the end.

Etching Process Overview

Laser Etching in FPC Manufacturing

Laser etching helps shape flexible printed circuit boards with great accuracy. It uses a focused laser beam to take away material from the board’s surface. The laser can make very thin lines and spaces. This helps the etched fpc work really well. Laser etching lets you control tiny details in the fpc. You can change the laser settings for each design. This makes laser etching a good pick for prototypes and new electronics.

New improvements have made laser etching even better. Laser Direct Imaging (LDI) lets you put on solder masks with great control. You can make smaller solder mask bridges. This helps the board work better during assembly. Semiconductor lasers and new copper foil also help you get better results. These new ideas make flexible printed circuits work better and lower mistakes like misalignment or bending.

Tip: If you want your flexible printed circuit board to work better, try laser etching for its accuracy and flexibility.

| Advancement Type | Impact on FPC Etching Processes |

|---|---|

| Laser Direct Imaging (LDI) | Gives more control and lets you make smaller solder mask bridges. This helps the board work better. |

| Copper Foil Innovations | New thin, high-conductivity foils help flexible electronics work better. |

| Emerging Technologies | Laser etching and nanocoatings make foil stick better and help electricity flow. |

Chemical Etching for FPCs

Chemical etching uses a chemical reaction to take away copper from the flexible printed circuit board. You put a resist pattern on the board to keep some areas safe. The chemical then removes the copper you do not want. This leaves the circuit pattern you need. Chemical etching works well when you need to make lots of pcbs at once.

Chemical etching gives steady results for big orders. It does not cost a lot and works for many designs. But laser etching gives you more control over small details and lowers the chance of mistakes. If you need your board to work really well, especially for tricky or small jobs, laser etching is often the best choice.

Precision in Etched FPCs

Laser Accuracy and Detail

Laser etching is great for making flexible pcbs with tiny details. The laser beam makes very thin lines and spaces. You can get features that are only a few microns wide. This helps you build circuits that need exact sizes. You can change the laser settings for each job. This means you can work with hard patterns and small parts. Laser etching does not touch the board. This keeps the board safe from damage while making or putting it together.

Note: Laser etching is good for testing new ideas. It also helps when you need special shapes or advanced electronics.

Here is what laser etching can do:

- It gives high accuracy for small designs

- It lowers the chance of bending or warping

- It lets you change layouts easily

Chemical Process Tolerances

Chemical etching works well for making lots of boards at once. You use a chemical to take away copper you do not want. This is best for big batches of flexible circuits. The lines and spaces may not be as exact as with lasers. You might see small changes in size. These changes can affect how your circuits work, especially if they need to be very fast. Chemical etching is still used a lot because it costs less and is good for making many boards.

Pick chemical etching if you want:

- Steady results for big orders

- Lower prices for simple designs

- Good performance for basic layouts

Tip: Think about what your design needs before you choose. If you need very exact circuits, pick the process that gives the most precision.

Production Speed and Throughput

Laser Process Efficiency

You want your etched fpc to move quickly from design to finished product. Laser technology helps you speed up manufacturing because it works without masks or long setup times. You can switch designs fast. This means you can test new ideas and make changes without waiting. The laser process uses computer control, so you get the same results every time. You do not need to stop for tool changes. This keeps your flexible pcbs moving through the line.

Laser etching also reduces waste. You only remove what you need. This helps you save material and lower costs. You can count on high performance and reliability, even for small batches or custom jobs. If you need to make flexible circuits for assembly in a hurry, laser etching gives you a clear advantage.

Tip: Use laser etching when you need fast turnaround and high accuracy for your flexible designs.

Chemical Etching Scalability

Chemical etching stands out when you need to make many boards at once. You can process large panels in a single batch. This makes chemical etching a good choice for high-volume manufacturing. You set up the process once, then run many flexible boards through the same steps. This saves you time and money for big orders.

You may see some limits with chemical etching. The process can take longer for complex patterns. You also need to handle chemicals safely. Still, chemical etching gives you steady results for mass production. You can trust this method for basic layouts and large runs.

| Method | Best For | Speed | Batch Size |

|---|---|---|---|

| Laser Etching | Prototypes, small runs | Very Fast | Small/Medium |

| Chemical Etching | Mass production | Fast | Large |

Note: Choose chemical etching if you want to scale up production and keep costs low for simple designs.

Cost Comparison

Equipment and Setup Costs

Laser etching machines cost a lot at first. You need to buy special machines with advanced parts. These machines use Laser Direct Imaging or semiconductor lasers. They are expensive because they are very precise. You also need special computer programs and trained workers. Setting up takes longer, but you get more accuracy and can make custom designs.

Chemical etching machines cost less to start. You only need tanks, pumps, and safety gear. The setup is easy and fast. You do not need special programs or much training. Chemical etching is good for making many boards at once. You save money if you make big batches or simple designs.

| Cost Factor | Laser Etching | Chemical Etching |

|---|---|---|

| Initial Investment | High (advanced machines) | Low (basic equipment) |

| Setup Time | Longer (software, training) | Short (simple process) |

| Flexibility | High (custom designs) | Moderate (batch focus) |

Note: Laser etching costs more, but it gives you better results and more reliable flexible pcbs.

Ongoing Process Expenses

You should think about costs that keep coming when you choose a process. Laser etching uses less material and makes less waste. You do not need masks or chemicals, so you save money over time. Laser machines cost more to fix, but they work better and make fewer mistakes. You also spend less fixing boards because the laser does not touch them.

Chemical etching costs less each day. You need to buy chemicals and change them often. You must get rid of waste and follow safety rules. It is easy to take care of the machines, but you spend more on chemicals and waste. Chemical etching is best for making lots of simple boards, but you might see more mistakes in tricky designs.

- Laser etching: More to fix, less waste, saves money for advanced jobs.

- Chemical etching: Easier to fix, more chemical costs, more waste, best for big orders and simple boards.

Tip: Pick laser etching to make less waste and get better boards. Choose chemical etching if you want to save money on lots of simple boards.

Environmental Impact of Etching

Laser Process Sustainability

You want your etched fpc to work well and be eco-friendly. Laser stripping is a cleaner way to make flexible pcbs. This process uses a strong light to take away material. You do not need to use harsh chemicals for this. By picking laser stripping, you help the environment. The laser only takes away what you need, so there is less waste.

Laser stripping also uses less energy than old ways. This helps the planet because you use less power and make less trash. You do not have to deal with dangerous chemicals, so your workspace is safer. Many companies now use laser stripping to follow strict green rules and make assembly better.

- Laser stripping makes less waste.

- You use less power with this method.

- You do not use dangerous chemicals, so it is safer.

- This method helps you reach green goals for flexible electronics.

Tip: If you want your company to look greener, laser stripping is a smart choice for flexible pcbs.

Chemical Waste and Emissions

Chemical stripping is still used a lot to make pcbs, mostly for big orders. You use chemicals to take off copper and shape the circuit. This makes liquid waste that needs careful handling. Chemical stripping can make fumes and dangerous leftovers. These things are bad for the environment.

You need special tools to clean up and throw away chemical waste. This makes your job cost more and harder to do. If you do not handle chemical waste right, you can hurt the environment and break safety laws. Chemical stripping also uses more power than laser stripping, so it is less efficient.

| Process | Waste Produced | Energy Use | Safety Concerns |

|---|---|---|---|

| Laser Stripping | Minimal | Low | Low |

| Chemical Stripping | High | High | High |

Note: You can make your company safer and greener by using less chemical stripping in your work.

Material and Design Flexibility

Laser Compatibility with FPC Materials

You need to pick the best process for your etched fpc. Laser technology works with many flexible pcb materials. You can use lasers on polyimide, PET, and some special laminates. The laser does not touch the board’s surface. This means you do not damage the layers. Your flexible layers stay strong and thin. Lasers can make tiny features without causing heat problems. This helps your circuits work better and last longer.

Lasers let you change settings for each material. You get smooth cuts and clean edges. This makes it easier to put together your circuits. Your flexible circuits can last longer. If you want to try new materials or designs, lasers let you test ideas.

Tip: Pick laser etching if you want to use special materials or make your flexible circuits better.

Chemical Process Versatility

Chemical etching gives you another way to be flexible. You can use it on many copper-clad laminates. It works for simple and hard pcb layouts. You can make lots of boards at once with steady results. Chemical etching lets you make many shapes and sizes. This helps you meet different design needs.

Here is a quick look at how each method helps with design flexibility:

| Method | Material Range | Design Complexity | Batch Size |

|---|---|---|---|

| Laser | Wide | High | Small/Medium |

| Chemical | Moderate | Moderate/High | Large |

Pick chemical etching if you want to make many boards with the same design. This process helps you save money and make lots of boards. You can use it for basic and advanced layouts. But it may not work as well for very thin or heat-sensitive materials.

Note: Think about your design and material needs before you choose. The right process will help you get the best flexible electronics.

Application Suitability for Etched FPCs

Prototyping and Small Batch Production

When you start a new project, you want things to move fast. Laser etching is good for making prototypes and small batches. You can change your design quickly and see results soon. You do not need special masks or tools. This saves you time and money at the start.

Laser technology helps you make tiny details on flexible pcbs. You can change the settings for each job. This lets you try new layouts and materials without waiting long. If you need to fix something, you can update your design and start again fast. You get clean edges and high accuracy. This helps you check your circuits before making more.

Tip: Pick laser etching for prototypes or small batches. It is great for testing new ideas and getting quick results.

Benefits of Laser Etching for Prototyping:

- Fast design changes

- No masks or extra tools needed

- High detail and accuracy

- Lower setup costs for small runs

Mass Production and Complex Designs

If you want to make many units, you need a method that works for big jobs. Chemical etching is good for mass production. You can process many panels at once. This helps you meet high demand and keep your line moving. Chemical etching gives steady results for simple and hard layouts.

For tricky designs, you should know what each method can do. Chemical etching works for most normal layouts. But laser etching gives you more control for tiny features. If your etched fpc needs thin lines or special shapes, laser technology helps you get better results. Sometimes, you can use both methods together. For example, use chemical etching for the main circuit and laser for special cuts.

| Application Type | Best Method | Key Advantages |

|---|---|---|

| Prototyping/Small Batch | Laser Etching | Fast changes, high accuracy |

| Mass Production | Chemical Etching | Low cost, high throughput |

| Complex Designs | Laser Etching | Fine detail, design freedom |

Note: Pick the method that fits your needs. For big orders, chemical etching saves money. For advanced flexible circuits, laser etching gives better quality and reliability.

Always match your process to your project goals. Think about how many you need, the detail in your design, and your materials. This helps you get the best results for both performance and cost.

Pros and Cons Table

When you look at laser and chemical etching for flexible pcbs, you notice big differences. Each method works better for different needs. You should pick the one that matches your project and design. The table below shows what each method is good and bad at for etched fpc production.

| Feature | Laser Etching | Chemical Etching |

|---|---|---|

| Precision | High accuracy for fine details | Good for basic layouts |

| Speed | Fast setup and quick changes | Efficient for large batches |

| Cost | Higher initial investment | Lower startup costs |

| Waste | Minimal material loss | More chemical waste |

| Flexibility | Works with many flexible materials | Best for standard pcb laminates |

| Reliability | Consistent results, less damage | Reliable for mass production |

| Environmental Impact | Cleaner, fewer emissions | Needs careful waste management |

| Assembly | Smooth edges, easy integration | May need extra cleaning |

| Design Complexity | Handles advanced and custom designs | Suits simple and moderate designs |

Tip: Pick laser etching if you want very exact and flexible flexible pcbs. Chemical etching is better for making lots of simple boards.

Pros of Laser Etching:

- You get very fine details.

- You can change your design fast.

- You make less waste and get steady results.

Cons of Laser Etching:

- The machines cost a lot.

- You need trained people to run them.

Pros of Chemical Etching:

- You save money on big orders.

- You can make many boards at the same time.

Cons of Chemical Etching:

- You have to deal with more waste.

- You do not get as much detail in hard designs.

Think about what your project needs before you choose. Your choice will change how good and strong your flexible electronics are.

You need to choose the right process for your etched fpc to get the best performance and reliability. Laser works well for flexible pcbs that need high accuracy and quick changes in manufacturing. Chemical methods suit mass production and basic pcb layouts. You should focus on your assembly needs, cost limits, and design goals. If you want better flexible circuits, send us your questions or fill out our contact form. Our experts can help you pick the best solution.

FAQ

What makes laser etching better for flexible PCB prototypes?

Laser etching gives you precise control over tiny features. You can change designs quickly. You do not need masks or chemicals. This method helps you test new ideas and get fast results.

Can chemical etching handle complex flexible circuit designs?

Chemical etching works best for simple or moderate layouts. You may see limits with very fine details. For advanced designs, you should use laser etching to get better accuracy.

Is laser etching safer for the environment than chemical etching?

Laser etching does not use harsh chemicals. You produce less waste and fewer emissions. This method helps you meet green standards and keeps your workspace safer.

How do costs compare between laser and chemical etching?

Laser etching costs more at first. You pay for advanced machines and training. Chemical etching costs less to start and works well for big orders. You should pick based on your project size and detail needs.

Which method should you choose for mass production?

You should use chemical etching for mass production. This process handles large batches and keeps costs low. Laser etching suits small runs or designs that need high precision.

2025-11-26

2025-11-26

BEST

BEST

.png)

.png)

.png)

.png)

.png)