When you search for the best rohs flex pcb for modern electronics, consider products like rigid-flex circuits, PET and polyimide flexible pcb, and TPU circuits. Top manufacturers such as POE, HT Global Circuits, and Suntek Electronics deliver reliable pcb solutions with rohs certification. You need to focus on sectors like aerospace, automotive, medical, LED, and wearables. Always check pcb features and manufacturer reliability before choosing flexible pcb for your electronics project.

Top RoHS Flex PCB Products

Rigid-Flex PCB Overview

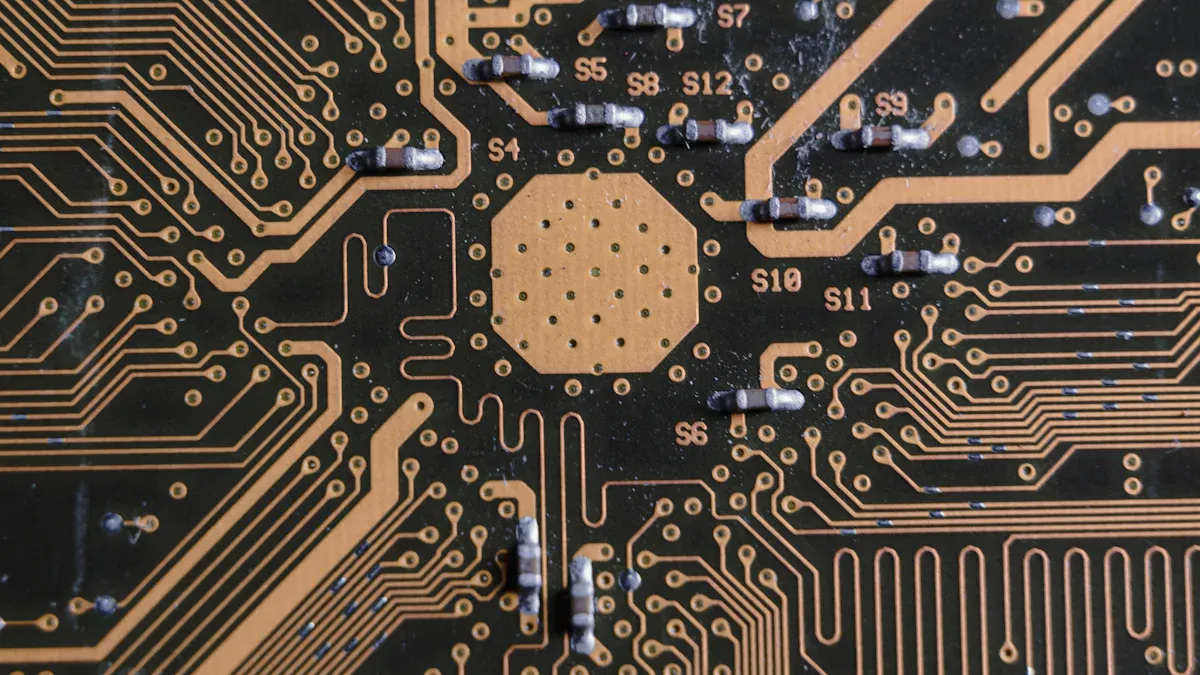

You encounter rigid-flex pcb technology in many advanced electronics. This type of pcb combines rigid and flexible layers, allowing you to design compact devices with complex shapes. Rigid-flex circuits support high-density component placement and reduce the need for connectors, which improves reliability. You see these pcbs in aerospace controls, medical imaging equipment, and automotive sensors. The flex layers withstand repeated bending, making them ideal for dynamic environments. When you choose a rigid-flex pcb, you ensure your electronics meet strict durability and performance standards.

Tip: Rigid-flex pcbs simplify assembly and reduce weight, which is crucial for portable electronics and wearables.

PET and Polyimide Flex PCBs

PET and polyimide flexible pcb options offer you excellent versatility for modern electronics. PET-based flex circuits provide cost-effective solutions for consumer devices, such as fitness trackers and smart cards. Polyimide flexible pcb materials deliver superior thermal stability and chemical resistance, which you need for industrial and medical applications. You benefit from the flexibility of these pcbs, as they can bend, twist, and fold without losing electrical integrity. Manufacturers design PET and polyimide flex circuits to meet RoHS standards, ensuring your electronics remain environmentally friendly.

-

Key advantages of PET and polyimide flex circuits:

-

Lightweight and thin for compact electronics

-

High resistance to heat and chemicals

-

Reliable performance in flexible and dynamic environments

-

TPU Circuits for LED and Wearables

You rely on TPU flex circuits for LED lighting and wearable electronics. TPU, or thermoplastic polyurethane, offers exceptional flexibility and durability. These flexible pcb solutions withstand repeated stretching and bending, which is essential for fitness bands, smart clothing, and flexible LED strips. TPU flex circuits resist moisture and abrasion, making them suitable for outdoor and medical electronics. You can integrate TPU-based flex circuits into curved surfaces and dynamic assemblies, expanding your design possibilities.

Note: TPU flex circuits help you create innovative electronics that require both flexibility and long-term reliability.

Multilayer SMT Flex PCB Assembly

Multilayer SMT flex pcb assemblies represent the most advanced solutions for high-performance electronics. You find these pcbs in industrial, aerospace, and consumer markets. Manufacturers use Megtron 6 pcb material to achieve superior thermal endurance and reliability. These flex assemblies meet RoHS requirements and offer halogen-free options, ensuring compliance with global environmental standards.

|

Feature |

Details |

|---|---|

|

Material |

Megtron 6 PCB |

|

RoHS Compliance |

Yes |

|

Halogen-free Options |

Available |

|

Applications |

Industrial, Aerospace, Consumer Markets |

You benefit from robust thermal endurance, which allows these flexible pcb assemblies to operate in extreme-temperature environments. The design supports strict harmful-substance limitations, so you meet RoHS flex pcb standards with confidence.

|

Feature |

Description |

|---|---|

|

Thermal Endurance |

Engineered for robust thermal endurance, suitable for extreme-temperature environments. |

|

RoHS Compliance |

Meets RoHS requirements and strict harmful-substance limitations. |

|

Environmental Compliance |

Halogen-free options available, ensuring compatibility with global regulations. |

You should consider multilayer SMT flex pcb assemblies when your electronics demand high reliability, environmental compliance, and advanced performance.

Leading Flex PCB Manufacturers

POE and HT Global Circuits

You find POE and HT Global Circuits at the forefront of flex pcb manufacturers. Both companies hold RoHS, ISO, UL, and IPC certifications. These certifications guarantee that you receive safe and reliable pcb products for your electronics. POE offers a wide range of flexible pcb solutions, including single-sided, double-sided, and multilayer flex circuits. You can use their products in automotive, aerospace, and medical electronics. HT Global Circuits specializes in advanced flex pcb assembly and rigid-flex designs. You benefit from their expertise in high-density interconnects and precision manufacturing. Their flex circuit manufacturer capabilities support complex electronics that require durability and flexibility.

Tip: Choose POE or HT Global Circuits when you need certified pcb products for demanding applications.

|

Manufacturer |

Certifications |

Product Range |

Application Sectors |

|---|---|---|---|

|

POE |

RoHS, ISO, UL, IPC |

Single/Double/Multilayer Flex PCB |

Automotive, Aerospace, Medical |

|

HT Global Circuits |

RoHS, ISO, UL, IPC |

Rigid-Flex, HDI, SMT Flex PCB |

Industrial, Medical, Consumer |

Suntek Electronics

Suntek Electronics stands out among flex pcb manufacturers for its commitment to quality and compliance. You see their RoHS, ISO, UL, and IPC certifications on every flexible pcb they produce. Suntek delivers flexible pcb solutions for LED lighting, industrial controls, and wearable electronics. Their product range includes polyimide and PET flex circuits, as well as multilayer flexible pcb assemblies. You rely on Suntek for consistent performance and fast turnaround times. As a flex circuit manufacturer, Suntek focuses on innovation and customer support. You can trust their flexible pcb products for both prototyping and mass production.

-

Suntek Electronics Highlights:

-

Full RoHS and ISO compliance

-

Flexible pcb options for LED, industrial, and wearable electronics

-

Fast delivery and technical support

-

Gekunflex for Wearable Devices

Gekunflex leads the market in flexible pcb solutions for wearable electronics. You choose Gekunflex when you need ultra-flexible, lightweight pcb designs. Their products meet RoHS, ISO, UL, and IPC standards, ensuring safety and reliability. Gekunflex specializes in TPU and polyimide flex circuits that withstand repeated bending and stretching. You find their flexible pcb assemblies in smart clothing, fitness bands, and medical wearables. As one of the top flex pcb manufacturers, Gekunflex offers custom design services and rapid prototyping. You benefit from their expertise in flexible electronics for dynamic applications.

Note: Gekunflex provides flexible pcb solutions that support innovation in wearable technology.

|

Manufacturer |

Certifications |

Product Range |

Application Sectors |

|---|---|---|---|

|

Gekunflex |

RoHS, ISO, UL, IPC |

TPU, Polyimide Flex PCB |

Wearables, Medical, LED |

You should always verify certifications and review product specifications before selecting a flex circuit manufacturer. Reliable flex pcb manufacturers help you achieve compliance and performance in your electronics projects.

Features and Benefits of RoHS Flex PCBs

Compliance and Certifications

You need to confirm that your flexible pcb meets strict compliance standards. RoHS flex pcb products support global regulations and help you avoid hazardous substances in electronics. Manufacturers provide certifications that include CE, FCC, RoHS, UL, and IP ratings. These certifications guarantee the quality and safety of your pcb. You can trust that your flexible printed circuit boards will pass environmental and safety audits.

-

CE, FCC, RoHS, UL, and IP ratings ensure your pcb meets international standards.

-

Certified flexible pcb products protect your electronics and support responsible manufacturing.

Flexibility and Material Choices

You benefit from a wide range of material options in flex pcb design. Flexible pcb solutions use polyimide, PET, and TPU to achieve different levels of flexibility and durability. You can select materials that match your electronics requirements. Polyimide offers high thermal stability, while PET provides cost-effective flexibility. TPU supports advanced flex pcb design for wearables and LED applications. You improve the quality of your electronics by choosing the right flexible material.

Tip: Select flexible pcb materials that match your device’s bending, folding, and stretching needs.

Durability and Reliability

You rely on the durability of your flexible pcb in demanding environments. Quality flex pcb design uses advanced materials like Megtron 6, which delivers high thermal performance and process reliability. You get robust thermal endurance, suitable for lead-free soldering and multilayer lamination cycles. The material features high decomposition temperature and strong T260/T288 performance. Superior CAF resistance and reliable through-hole plating durability ensure your pcb lasts longer. These features support electronics with more than 20 layers or high-speed HDI architectures.

-

Megtron 6 provides high thermal endurance and process reliability.

-

Reliable through-hole plating and CAF resistance improve pcb quality.

Application Suitability

You can use flexible pcb products in many electronics sectors. Flex pcb design supports aerospace, automotive, medical, LED, and wearable devices. You achieve high quality and reliability in each application. Flexible printed circuit boards adapt to complex shapes and dynamic environments. You improve your device’s performance by choosing the right flex pcb for your application.

|

Application Sector |

Flex PCB Benefit |

Quality Impact |

|---|---|---|

|

Aerospace |

Lightweight, durable |

High reliability |

|

Automotive |

Flexible, heat-resistant |

Long lifespan |

|

Medical |

Safe, certified |

Patient safety |

|

LED |

Bendable, moisture-proof |

Consistent lighting |

|

Wearables |

Stretchable, thin |

Comfort and function |

You maximize the quality of your electronics by matching flex pcb design to your device’s needs.

Flex PCB Assembly and Comparison

Assembly Services and Standards

You need reliable flex pcb assembly services to achieve high performance in your electronics. Leading flexible circuit board manufacturers offer advanced assembly options, including surface mount technology, through-hole soldering, and automated inspection. You can select flex pcb suppliers who provide turnkey solutions, from prototyping to mass production. These suppliers follow strict standards such as IPC-A-610 and ISO 9001, which guarantee quality and consistency in every flexible pcb. You benefit from flexible pcb manufacturing processes that support both single-layer and multilayer designs. Many flex pcb suppliers offer fast turnaround times and competitive pricing, so you can meet project deadlines without sacrificing quality.

Tip: Always request assembly certifications and process documentation from your flex pcb suppliers. This ensures your flexible pcb meets industry standards and delivers reliable performance.

You can choose flex pcb assembly services that include design support, material selection, and final testing. High-performance flex board assembly requires precise handling and expert knowledge. You should compare service options, such as lead-free soldering, automated optical inspection, and custom packaging. These features help you achieve high-performance solutions for demanding electronics applications.

Product Comparison Table

You want to compare flex pcb assembly products by compliance, performance, and fit for application. The table below highlights key features from top flexible circuit board manufacturers and flex pcb suppliers. You can use this comparison to select the best flexible pcb for your electronics project.

|

Product Type |

Compliance |

Performance Level |

Application Fit |

Assembly Service Options |

Pricing Range |

Quality Rating |

|---|---|---|---|---|---|---|

|

Rigid-Flex PCB |

RoHS, IPC |

High-performance |

Aerospace, Medical |

SMT, AOI, Lead-free Solder |

$$$ |

⭐⭐⭐⭐⭐ |

|

PET Flex PCB |

RoHS, ISO |

Standard |

Consumer, LED |

SMT, Manual Solder |

$ |

⭐⭐⭐⭐ |

|

Polyimide Flex PCB |

RoHS, UL |

High-performance |

Automotive, Industrial |

SMT, AOI, Custom Packaging |

$$ |

⭐⭐⭐⭐⭐ |

|

TPU Flex PCB |

RoHS, IPC |

High-performance |

Wearables, LED |

SMT, AOI, Rapid Prototyping |

$$ |

⭐⭐⭐⭐⭐ |

|

Multilayer SMT Flex PCB |

RoHS, IPC |

High-performance |

Industrial, Aerospace |

SMT, AOI, Lead-free Solder |

$$$ |

⭐⭐⭐⭐⭐ |

You should evaluate each flex pcb assembly option based on your device requirements and budget. High performance flex board solutions deliver superior reliability and durability. Flexible pcb manufacturing standards ensure consistent quality across all products. You can trust flexible circuit board manufacturers who provide transparent pricing and comprehensive service packages.

Note: Comparing assembly services and product features helps you select the right flexible pcb for your electronics, ensuring long-term quality and performance.

How to Choose RoHS Flex PCBs

Assessing Device Needs

You start by identifying the requirements of your electronics project. Consider the size, shape, and flexibility your device demands. If your design needs repeated bending or folding, select a flexible pcb that supports dynamic movement. For compact electronics, choose a flex pcb smt assembly with thin layers and lightweight materials. You improve device reliability by matching the flex pcb smt assembly to your operating environment. Always check if your application needs moisture resistance or thermal stability.

Tip: Write down your device’s mechanical and electrical needs before you compare pcb options.

Evaluating Manufacturer Reliability

You must evaluate the reliability of each pcb manufacturer. Look for companies with a strong track record in flexible pcb production. Reliable manufacturers offer consistent quality and fast delivery. You should review customer feedback and case studies for flex pcb smt assembly projects. Choose suppliers who provide technical support and clear documentation. Reliable partners help you avoid delays and ensure your electronics meet industry standards.

|

Manufacturer Criteria |

Why It Matters |

|---|---|

|

Experience |

Ensures quality and expertise |

|

Certifications |

Confirms compliance |

|

Support |

Solves issues quickly |

Verifying Certifications

You need to verify all certifications before you select a flexible pcb. RoHS, ISO, UL, and IPC certifications confirm that your flex pcb smt assembly meets global safety and environmental standards. Ask manufacturers for certification documents and test reports. Certified pcb products protect your electronics from hazardous substances. You reduce risk by choosing flexible pcb assemblies with verified compliance.

Note: Always request certification proof for every flex pcb smt assembly you order.

Matching Features to Applications

You match the features of each flex pcb smt assembly to your application. For wearables, select flexible pcb designs with TPU or polyimide for comfort and durability. In automotive or aerospace electronics, choose flex pcb smt assembly with high thermal endurance. LED devices need flexible pcb solutions that resist moisture and support stable lighting. You improve device performance by aligning pcb features with your project’s needs.

-

Flexible pcb features to consider:

-

Material type

-

Layer count

-

Bending radius

-

Environmental resistance

-

You make better decisions by comparing the specifications of each flex pcb smt assembly to your electronics requirements.

You now have a clear overview of the top flex pcb products and flexible pcb manufacturers for electronics. Choose flexible pcb solutions that meet RoHS standards and fit your application needs. Reliable flex pcb options deliver compliance and long-term performance. Use the comparison tips to select the best flexible pcb for your project.

-

Review product features and certifications before you decide.

-

Contact us with your questions or send an inquiry using our email or online form.

Selecting the right flex pcb ensures your electronics achieve quality and reliability.

2025-11-25

2025-11-25

BEST

BEST

.png)

.png)

.png)

.png)

.png)