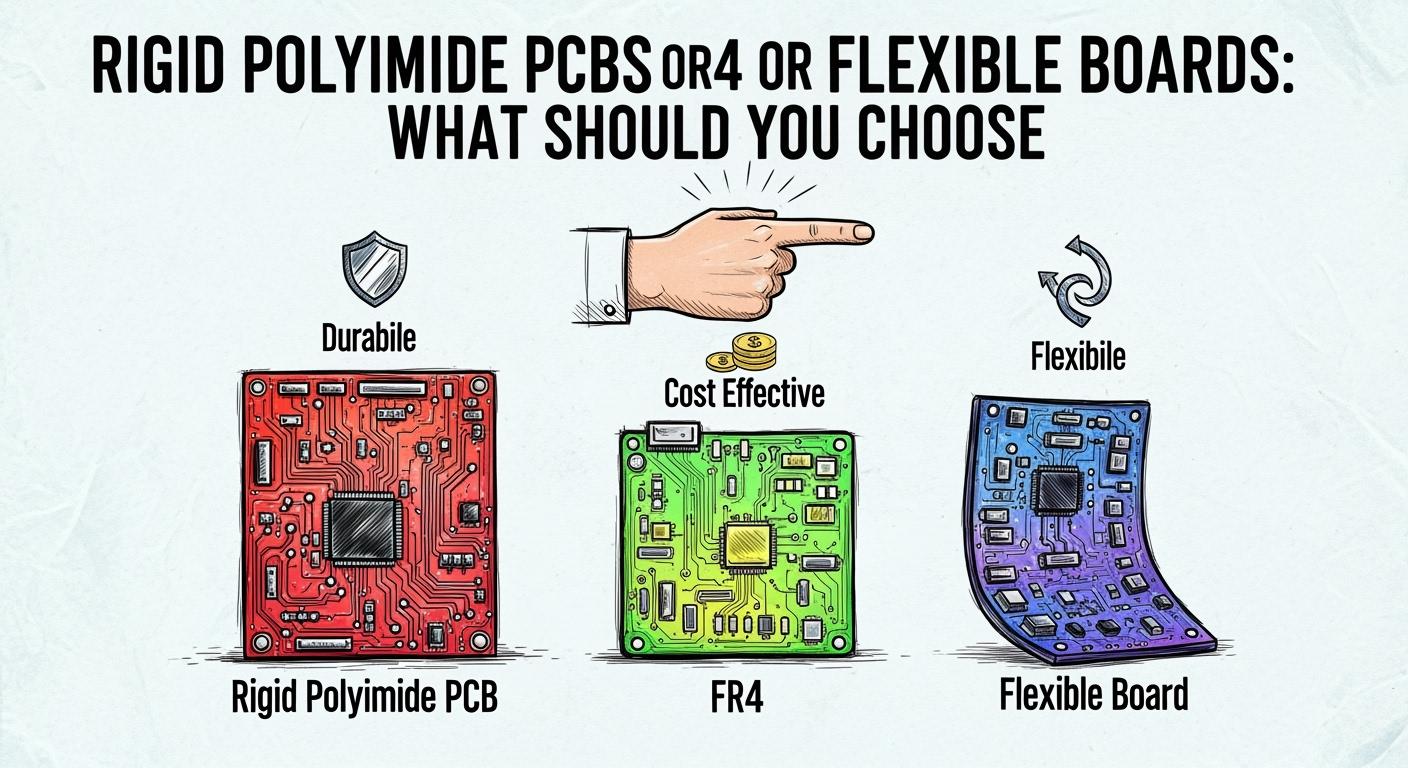

Choosing the right PCB depends on your specific needs. If you require high heat resistance, a rigid polymide pcb offers excellent performance and dominates about half the market for demanding applications. For cost-effective and durable solutions, many electronics manufacturers prefer FR4 pcbs, which hold around 30% of the market. Flexible pcbs work best in compact devices where bending and lightweight design matter. Your decision should focus on performance, reliability, and budget. Review your project’s goals before selecting the best option.

Key Takeaways

- Choose rigid polyimide PCBs for high heat resistance and reliability in harsh environments like aerospace and medical devices.

- Select FR4 PCBs for cost-effective solutions in consumer electronics, offering a strong balance of performance and affordability.

- Opt for flexible PCBs when designing compact devices that require bending and lightweight features, such as wearables and mobile phones.

- Evaluate your project's specific needs, including temperature tolerance, mechanical strength, and cost, to select the best PCB type.

- Consult with PCB design experts to validate your design and optimize for quality and cost-efficiency.

Quick Comparison

Key Differences

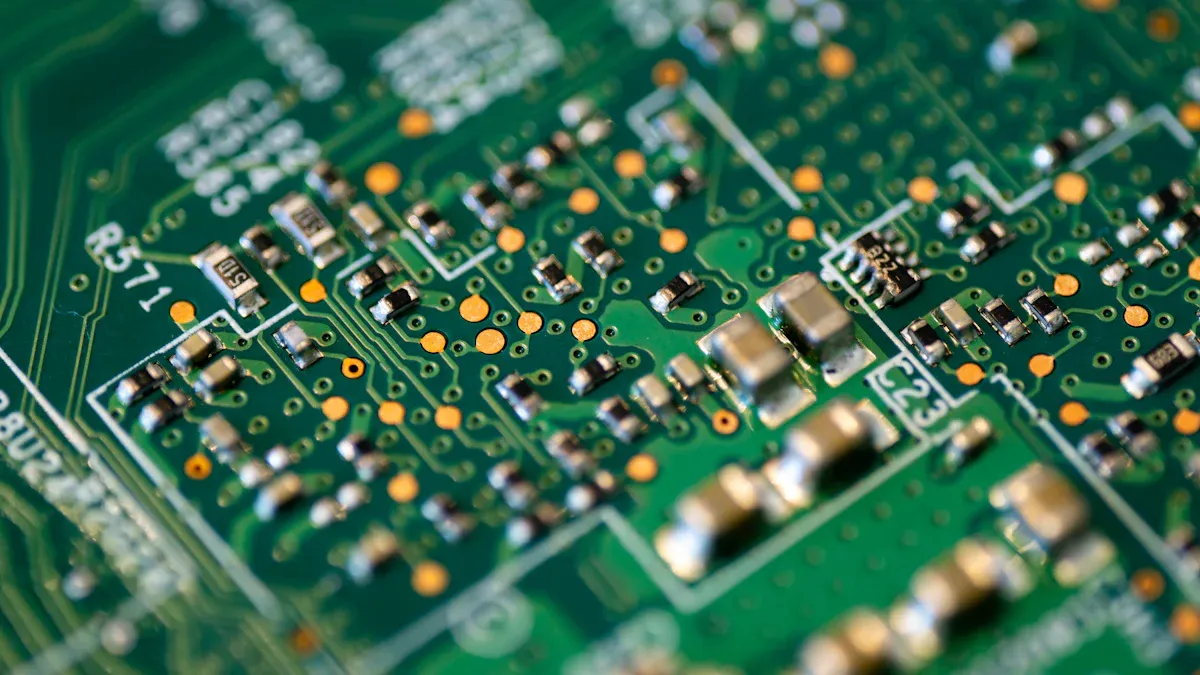

You need to understand the main differences between rigid polyimide pcbs, fr4, and flexible pcbs before making a decision. The table below highlights how each type performs in key areas:

| Property | Rigid Polyimide PCBs | FR4 PCBs | Flexible PCBs |

|---|---|---|---|

| Mechanical Strength | High | Very High | Moderate |

| Flexibility | Low | None | Excellent |

| Heat Resistance | Excellent | Good | Good |

| Cost | High | Moderate | Moderate to High |

| Best-fit Applications | Aerospace, Medical | Consumer Electronics, Industrial | Wearables, Mobile Devices |

Rigid polyimide pcbs offer excellent heat resistance and chemical stability. You can rely on them in harsh environments, especially where high temperatures are common. Fr4 pcbs use a fiberglass composite that gives you outstanding mechanical strength and reliable thermal performance. Flexible pcbs use polyimide materials, which allow you to bend and fold the board, making them ideal for compact or irregularly shaped devices.

Tip: If your project needs a board that can handle frequent bending or vibration, flexible pcbs provide the best solution.

Best Uses

You should match your application to the strengths of each PCB type:

- Choose rigid polyimide pcbs for aerospace, automotive, or medical devices where you need high reliability and resistance to heat and chemicals.

- Select fr4 pcbs for most consumer electronics, industrial controls, and general-purpose devices. Fr4 gives you a balance of cost, strength, and performance.

- Use flexible pcbs in wearables, mobile phones, and any device where space is tight or the board must flex during use.

Each type of pcb serves a unique role. When you compare fr4 to other options, you see why it remains the industry standard for many applications. However, flexible pcbs continue to grow in popularity for modern, compact electronics.

Rigid Polyimide PCB

Pros

You gain several advantages when you choose a rigid polymide pcb for your project. These boards excel in environments that demand high heat resistance, chemical stability, and mechanical strength. The table below summarizes the main benefits compared to other pcbs:

| Advantage | Description |

|---|---|

| Heat Resistance | Polyimide pcbs offer high heat resistance, providing stability over a wide temperature range. |

| Chemical Stability | They exhibit excellent chemical resistance, making them suitable for harsh environments. |

| Mechanical Strength | Polyimide pcbs have high tensile strength, ensuring durability and flexibility, unlike brittle materials such as FR4. |

You can rely on rigid polymide pcb solutions for outstanding signal integrity and biocompatibility. These boards maintain performance even under repeated sterilization resistance cycles. Their dynamic flexibility supports complex assemblies, while their reliability ensures long-term operation in demanding settings.

Cons

You should consider some drawbacks before selecting a rigid polymide pcb. The cost is higher than standard FR4 pcbs. Manufacturing processes for polyimide pcbs require advanced materials, which increases expenses. While these boards offer good mechanical strength, FR4 still provides greater rigidity in some cases. You may also find that flexible pcbs made from polyimide cost more than FR4, but they can reduce assembly costs due to fewer connections.

Note: Rigid polymide pcb options deliver excellent sterilization resistance and biocompatibility, but you must balance these benefits against your budget and mechanical needs.

Applications in Medical Device Design

Rigid polymide pcb technology plays a vital role in medical device design. You see these boards in implantable devices like pacemakers and defibrillators, where long-term reliability and biocompatibility are essential. Minimally invasive tools, such as endoscopes and robotic surgical arms, use polyimide pcbs for their dynamic flexibility and signal integrity. Wearable monitors, including skin patches for glucose or ECG tracking, depend on the integrity and sterilization resistance of these boards to meet critical medical requirements.

You benefit from design versatility, space efficiency, and fewer failure points. Polyimide pcbs withstand repeated sterilization resistance cycles, supporting the strict standards of medical device design. Their biocompatibility and signal integrity make them the preferred choice for applications where reliability and patient safety matter most.

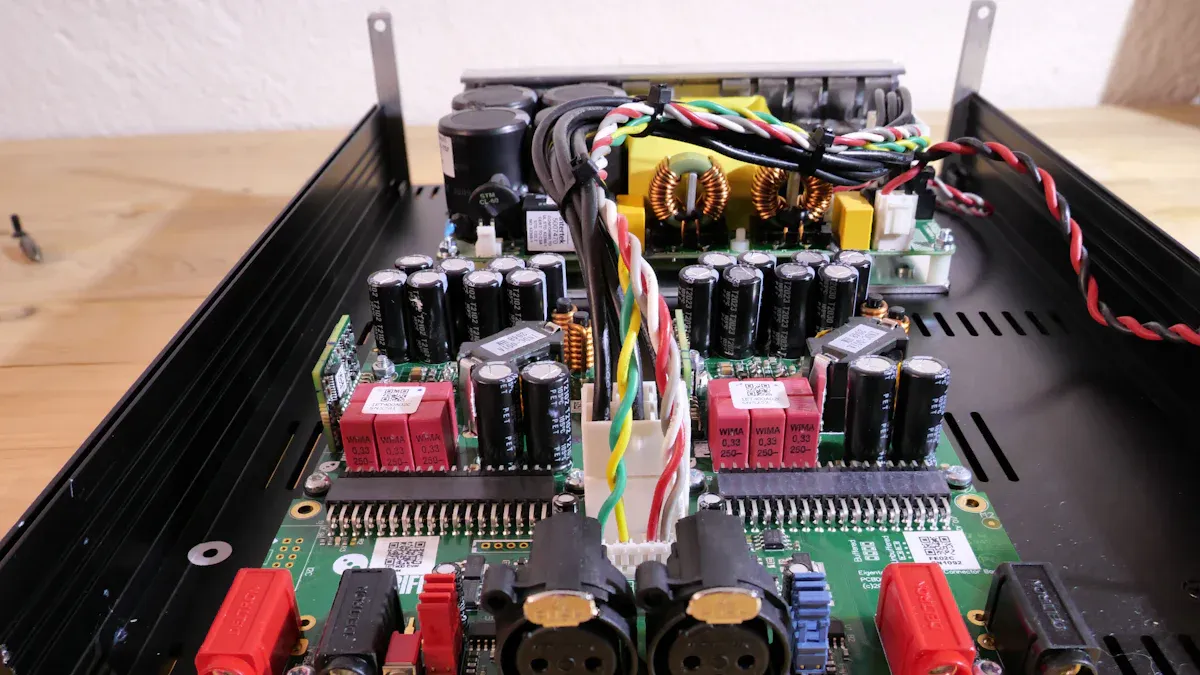

FR4 PCB

Pros

You will find that fr4 pcbs offer a strong balance of cost, strength, and ease of manufacturing. These boards use a glass-reinforced epoxy laminate, which gives you high mechanical strength for a wide range of applications. Manufacturers choose fr4 because the material is inexpensive and the production process is straightforward. This makes fr4 a popular choice when you need to manage costs without sacrificing quality.

| Benefit | Description |

|---|---|

| Cost-effectiveness | Fr4 materials are generally inexpensive due to their simple manufacturing process, making them a popular choice when cost pressure is high. |

| Mechanical strength | Fr4 is a glass-reinforced epoxy laminate that offers high mechanical strength, suitable for various applications. |

| Ease of manufacturing | The manufacturing process for fr4 is relatively straightforward, contributing to its widespread use in PCB production. |

You can rely on fr4 pcbs for consistent performance in most consumer and industrial electronics. The material supports multilayer designs, which helps you create complex circuits with high reliability.

Tip: If you want a proven solution for standard electronic devices, fr4 pcbs deliver dependable results at a reasonable price.

Cons

You should consider the limitations of fr4 before making your final decision. Fr4 pcbs do not handle high heat or repeated thermal cycling as well as some advanced materials. When exposed to thermal stress, these boards can develop issues like delamination or microcracks, which may reduce reliability. Fr4 also lacks flexibility, so it cannot bend or fold without damage. Moisture absorption can further impact the dielectric properties, leading to a decrease in overall performance under harsh conditions.

Note: For projects that require frequent bending or must withstand extreme temperatures, you may want to explore other pcb options.

Typical Applications

Fr4 pcbs appear in many industries because of their versatility and cost-effectiveness. You will see them in consumer electronics, automotive systems, and industrial controls. The following tables show where fr4 boards excel:

| Industry | Typical Applications |

|---|---|

| Consumer Electronics | Smartphones, tablets, televisions |

| Automotive Electronics | Sensors, infotainment systems, lighting |

| Industrial Systems | Control panels, automation systems, robotics |

| Industry | Typical Applications |

|---|---|

| Communication Equipment | Antenna bases, RF modules, microwave devices |

| Automotive Industry | Instrument panels, in-car entertainment |

| Other Fields | Aerospace, medical equipment, industrial equipment |

You can trust fr4 to provide a reliable foundation for most electronic products. Its widespread use in so many fields proves its value and adaptability.

Flexible PCB

Pros

You gain several advantages when you choose flexible pcbs for your design. These boards stand out for their ability to bend and fit into tight spaces. You can create lighter and thinner products, which is essential for modern electronics. Here are some key benefits:

- Flexible pcbs weigh 80 to 90% less than rigid boards, helping you reduce the overall weight of your device.

- The thin, compact construction saves space and allows you to add more components or features.

- You can bend and shape these boards to fit unique enclosures or moving parts.

- Fewer connectors and shorter interconnections improve signal integrity and lower electromagnetic interference.

| Advantage | Description |

|---|---|

| Weight Reduction | Flexible pcbs weigh much less than rigid options, ideal for portable devices. |

| Space Savings | Slim design frees up valuable real estate inside your product. |

| Design Flexibility | Boards can bend and conform to almost any shape. |

Tip: Flexible pcbs help you achieve innovative designs that would be impossible with traditional rigid boards.

Cons

You should also consider the drawbacks before selecting flexible pcbs. These boards require precise manufacturing and can cost more upfront, especially for complex layouts. Their unique structure can make repairs and maintenance more challenging. The following table summarizes the main limitations:

| Drawback | Description |

|---|---|

| High initial cost | Flexible pcbs often have higher startup costs, particularly for intricate designs. |

| Production difficulties | Manufacturing demands specialized equipment and expertise. |

| Limited lifespan | Repeated bending can cause fatigue, reducing the board’s life compared to rigid types. |

| Maintenance difficulties | Repairs can be tricky due to the flexible materials. |

| Size limitation | Production processes restrict the maximum size of flexible pcbs. |

| Material limitations | Polyimide and other materials may increase costs and impact the environment. |

Note: If your application requires frequent bending, plan for possible wear and consider the board’s expected lifespan.

Where to Use

You will find flexible pcbs in products that demand lightweight, compact, and reliable performance. These boards excel in medical devices, where ultra-thin design and biocompatibility matter. Robotics and automation systems use them for dynamic flexing and resistance to mechanical stress. Consumer electronics, such as wearables and foldable phones, rely on flexible pcbs for their ability to withstand repeated bending and fit into innovative form factors.

| Product Type | Driving Factors |

|---|---|

| Medical Devices | Ultra-thin design, biocompatibility, high reliability, sterilization compatibility |

| Robotics and Automation | Dynamic flexing, high cycle life, mechanical stress resistance |

| Consumer Electronics | Repeated bending, innovation in foldable and wearable devices |

You should choose flexible pcbs when your project requires space savings, weight reduction, and the ability to fit into unique shapes. These boards support advanced designs and help you deliver cutting-edge products.

Decision Guide

Checklist

Selecting the right PCB type requires you to evaluate your project’s unique requirements. Use this checklist to match your needs with the most suitable PCB option:

| Requirement | Rigid Polyimide PCB | FR4 PCB | Flexible PCB |

|---|---|---|---|

| Temperature Tolerance | Withstands up to 200°C, ideal for high-temp environments | Good for moderate temperatures | Good, but not as high as polyimide |

| Mechanical Strength | High tensile strength, durable | Very high rigidity, strong | Moderate, designed for bending |

| Flexibility | Low, mostly rigid | None, completely rigid | Excellent, bends and folds easily |

| Space Constraints | Moderate, not for tight spaces | Standard, not for compact areas | Excellent for limited or odd spaces |

| Cost Sensitivity | Higher cost, premium applications | Most cost-effective | Moderate to high, depends on design |

| Chemical Resistance | Excellent | Good | Good |

| Assembly Complexity | Moderate, advanced processes | Simple, standard processes | Complex, requires expertise |

Tip: Always start by listing your top three priorities—temperature, space, or cost. This approach helps you narrow down your options quickly.

You can also consider these key characteristics for each PCB type:

- Rigid Polyimide PCB: High heat and chemical resistance, solid structure, suitable for harsh environments.

- FR4 PCB: Strong, cost-effective, easy to manufacture, best for fixed components.

- Flexible PCB: Lightweight, bendable, fits irregular shapes, ideal for compact or moving parts.

Example Scenarios

To help you decide, review these common scenarios and see which PCB type fits best:

1. High-Temperature Environments

If you design equipment for aerospace, automotive, or industrial controls, you need a board that withstands extreme heat. Rigid polyimide PCBs perform well in these settings. You find them in solar-array harnesses, CubeSat buses, and e-motor sensor flex circuits. Their ability to handle up to 200°C ensures reliability where other materials fail.

2. Cost-Sensitive Consumer Electronics

When you work on products like smartphones, televisions, or control panels, cost and ease of manufacturing matter most. FR4 PCBs offer the best value. Their glass-reinforced epoxy laminate provides high mechanical strength at a low price. You see FR4 boards in most consumer and industrial electronics because they balance performance and budget.

3. Space-Constrained or Irregular Designs

If your device must fit into a small or uniquely shaped enclosure, flexible PCBs give you the freedom to innovate. You use them in wearables, foldable phones, and medical devices like catheter pull-wire flex circuits. Flexible PCBs allow you to bend and fold the board, making them perfect for applications with limited space or moving parts.

4. Medical Device Design

Medical devices demand reliability, biocompatibility, and sterilization resistance. Rigid polyimide and flexible PCBs both excel here. You find them in implantable devices, endoscopes, and wearable monitors. For example, intracardiac endoscope lighting strips use flexible PCBs that withstand repeated sterilization cycles.

5. Applications with Limited Bending

Some projects require a board that bends only during installation or maintenance. Semi-flex PCBs, made from thinner sections of FR4, provide a solution. You use them in static applications where minimal bending occurs, such as rework or assembly adjustments.

Note: Always consider assembly challenges. Flexible and semi-flex PCBs require careful handling and specialized assembly processes.

6. High-Speed Data and RF Applications

If your design involves high-speed data transfer or radio frequency circuits, such as 10 Gb/s USB-C cables or 6–40 GHz antennas, flexible and rigid polyimide PCBs deliver the electrical performance you need. Their excellent signal integrity supports advanced communication and imaging systems.

By matching your project’s requirements to these scenarios, you can confidently select the right PCB type. If you remain unsure, consult with a PCB design expert to ensure your choice meets all technical and budgetary needs.

You should select your PCB type based on your project’s unique needs. Rigid polyimide, FR4, and flexible PCBs each offer distinct advantages. Use the checklist to guide your decision. If you feel uncertain, consulting PCB design experts improves your process. Experts validate your design, identify strategic suppliers, and optimize for quality and cost-efficiency:

| Step | Description |

|---|---|

| Design validation | Experts analyze manufacturability and documentation to prevent delays. |

| Strategic supplier identification | Experts match technical requirements with manufacturing partners. |

| Comprehensive DFM review | Experts refine design for quality and cost. |

| Data-driven supplier selection | Experts compare vendor proposals using quantifiable data. |

Evaluate your requirements carefully. Advancements in PCB technology, such as ultra-fine line widths and embedded components, continue to shape future choices.

2025-10-28

2025-10-28

BEST

BEST

.png)

.png)

.png)

.png)

.png)