You need advanced technology to help your car work well. Automotive FPC Board solutions are important in today’s car electronics. They give flexibility and make things reliable. Picking the right automotive supplier is important. It can change how safe and well your car works. A good partner helps you get steady quality. They also help you follow tough industry rules.

Key Takeaways

- Pick automotive FPC board makers with important certifications like ISO9001 and IATF16949. This helps make sure you get good quality and follow rules.

- Ask for sample FPC boards before you buy a lot. This lets you check if the products are good and fit what you need.

- Find makers who give good customer support and answer fast to problems. This helps stop your project from being late.

- Check how much experience the supplier has and what they can do. This makes sure they can handle what your automotive project needs.

- Think about both price and service when you pick a supplier. This helps you get products you can trust and get them on time.

Choosing Automotive FPC Board Manufacturers

Picking the right automotive FPC board partner affects how well your car electronics work. You need to know how to find and check automotive pcb manufacturers for your project. This part gives you easy tips to help you choose wisely.

Key Selection Criteria

When you look for automotive pcb manufacturers, focus on a few main things. These points help you compare companies and pick the best one for you.

- Certifications and Standards: Find manufacturers with important certifications. These include ISO9001 for quality and IATF16949 for making car parts. These show the company follows strict rules for quality.

- Product Quality and Testing: Good automotive pcb manufacturers test every product with electricity. This makes sure each FPC board is safe and works well.

- Connector Options: Check if the manufacturer has different connectors like ZIF, LIF, and FFC FPC connectors. These choices help you design your products better.

- Time to Market: Fast delivery is important for car makers. Pick automotive pcb manufacturers who can send products quickly and still keep them high quality.

- Customer Support: Good support helps you fix problems fast. You need a supplier who answers quickly and gives technical help when you need it.

Tip: Always ask for sample FPC boards before you order a lot. This lets you see if the boards are good and fit your needs.

Supplier Experience and Capabilities

Experience and skills make some automotive pcb manufacturers better than others. You want a partner who knows what car makers need.

Beijida Electronics (BJD) is special because they focus on car supply. Their team has more than 20 years of experience. They use machines to make products and keep quality high. This helps them give custom solutions that meet tough car rules.

Here is a quick look at what you should check:

| Certification | Description |

|---|---|

| ISO9001 | Standard for managing quality |

| ISO13485 | Quality rules for medical devices |

| IATF16949 | Quality rules for making car parts |

| Experience | 20 years working in the field |

| Production | Machines make products with high standards |

You should also look for these things when picking automotive pcb manufacturers:

- Good ZIF, LIF, and FFC FPC connectors

- Fast delivery times

- Testing every product with electricity

Automotive pcb manufacturers with these skills can help you from start to finish. They help you follow rules and keep your products working well. If you pick experienced manufacturers, you lower risks and have a better chance to succeed.

Note: Top automotive pcb manufacturers spend money on research and new ideas. This helps them keep up with new car technology and trends.

If you use these tips and look for experience, you can find automotive pcb manufacturers who will help you reach your goals and give you great FPC boards for your car projects.

Understanding Automotive FPC and Flex PCB Technology

What Is an Automotive FPC Board?

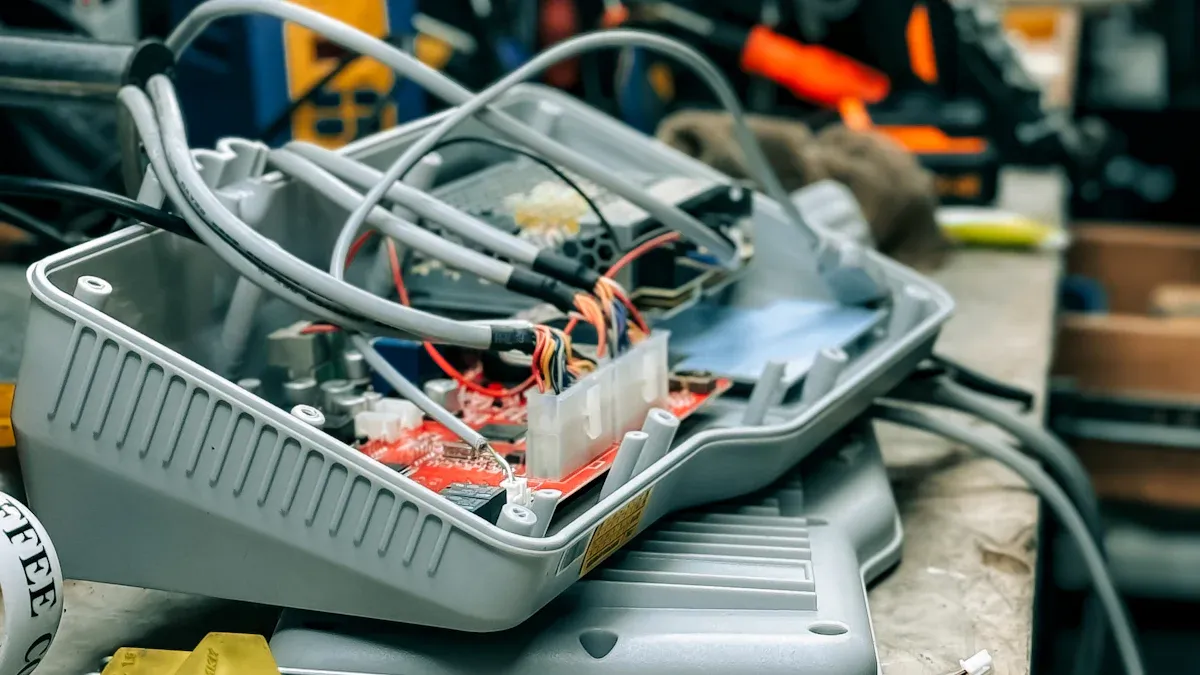

You can find flexible printed circuit boards in many cars today. An automotive fpc board is made with a base called polyimide film. This base helps the board stay strong in heat and lets it bend. Makers use a special process called photolithography to put metal lines on the board. These lines make up the circuits. Some boards have many layers and small parts built in. These boards are used in smart car systems like sensors and cameras for self-driving cars.

| Feature | Description |

|---|---|

| Base Material | Polyimide film for thermal stability and flexibility |

| Construction Process | Photolithography etches conductive traces |

| Circuit Complexity | Supports complex patterns, multiple layers, and integrated components |

| Applications | Used in sensors, cameras, and other advanced automotive systems |

Automotive fpc board technology helps cars have better and smaller electronics. This makes car electronics work well and last longer.

Flex PCB Advantages in Automotive Applications

Flexible printed circuits have more benefits than stiff boards. They can bend and stretch, so they handle bumps and shakes better. This makes them last longer in cars. You can twist and fold these boards to fit in small places. Flexible printed circuits are light, so cars do not get heavier. They can bend many times and still not break. There are fewer solder spots, so there are fewer things that can go wrong. These reasons make flexible pcb design great for car circuit boards.

| Advantage | Description |

|---|---|

| Flexibility | Bends and twists to fit 3D spaces |

| Lightweight | Reduces weight in vehicles |

| Durability | Survives millions of flex cycles |

| Reliability | Fewer interconnects lower failure risk |

| Shock Absorption | Handles shocks and vibrations better than rigid boards |

- Flexible printed circuits let you add more features in small spaces.

- People use flexible pcb in dashboards, lights, and safety parts.

FFC vs. FPC Connectors

You need the right connectors for flexible printed circuit boards. FFC and FPC connectors look alike but do not work the same way. FFC connectors need you to do a few steps to put them together. FPC connectors lock in place with one move, so you save time. FPC connectors have two contact spots for a stronger connection. They also clean out dirt better. FPC connectors can be put together by machines and can take heat up to 125 degrees Celsius.

| Feature | FFC Connectors | FPC Connectors |

|---|---|---|

| Locking Mechanism | Multiple assembly actions | One-action locking mechanism |

| Contact Points | Single contact point | Two contact points |

| Foreign Matter Removal | Standard performance | Enhanced performance |

| Automation Support | Limited | Supports automated assembly |

| Heat Resistance | Standard | Up to 125°C |

Picking the right flexible printed circuit connectors makes your car boards better. Fpc technology helps you keep up with what cars need today. Flexible printed circuits and flexible circuit boards are changing how car electronics are made.

Automotive PCB Manufacturers and Industry Standards

Automotive PCB Certifications

You need to look at certifications when picking a supplier. These show the company cares about safety and quality. The most important ones are IATF 16949 and ISO 9001. IATF 16949 is needed for car supply chains. ISO 9001 is used all over the world. It helps companies meet what customers want. Many top suppliers also have other certifications. These include safety and caring for the environment.

| Certification | Description |

|---|---|

| IATF 16949 | Automotive quality management standard |

| ISO 9001 | Globally recognized standard for quality management |

| ISO 14001 | Standard for environmental management systems |

| ISO 13485 | Quality management for medical devices |

| UL | Certification for product safety |

You should ask your supplier to show these certifications. This helps you avoid problems and makes sure your project is safe.

Material Choices for Automotive FPC Boards

The materials you pick change how your board works. Polyimide is used most for automotive pcb boards. It can handle heat and is very stable. Polyimide is also flexible and light. These things make it good for small and complex designs. You see polyimide in flexible screens and wearable tech. It is also in high-density circuits for cars.

| Material Type | Characteristics |

|---|---|

| Polyimide | High heat resistance, good stability, flexibility, lightweight, easy to shape |

When you choose materials, look for these things:

- Can bend and flex

- Handles high heat

- Good for electricity

- Not heavy

These help your board last longer and work well in cars.

Compliance and Safety Requirements

You must follow rules when making automotive pcb boards. IPC standards help with quality and reliability. You also need to meet safety rules like DIN 30 710. Your board needs the right safety marks for each place. These marks show your board is safe and meets rules.

- Follow IPC standards for quality and reliability.

- Meet DIN 30 710 for construction vehicles and machinery.

- Use correct safety markings for each market.

Note: If your board does not meet these rules, it can fail or cause legal trouble.

You should check that your supplier knows these rules. This keeps your board safe and ready for use.

Evaluating Manufacturers for Automotive PCB and FPC Boards

When you pick a partner for automotive PCB and flex pcb boards, you should look at more than just price or delivery speed. You need to check their quality systems, design help, and place in the world market. This helps you avoid problems and find a supplier who fits your needs as cars get smarter.

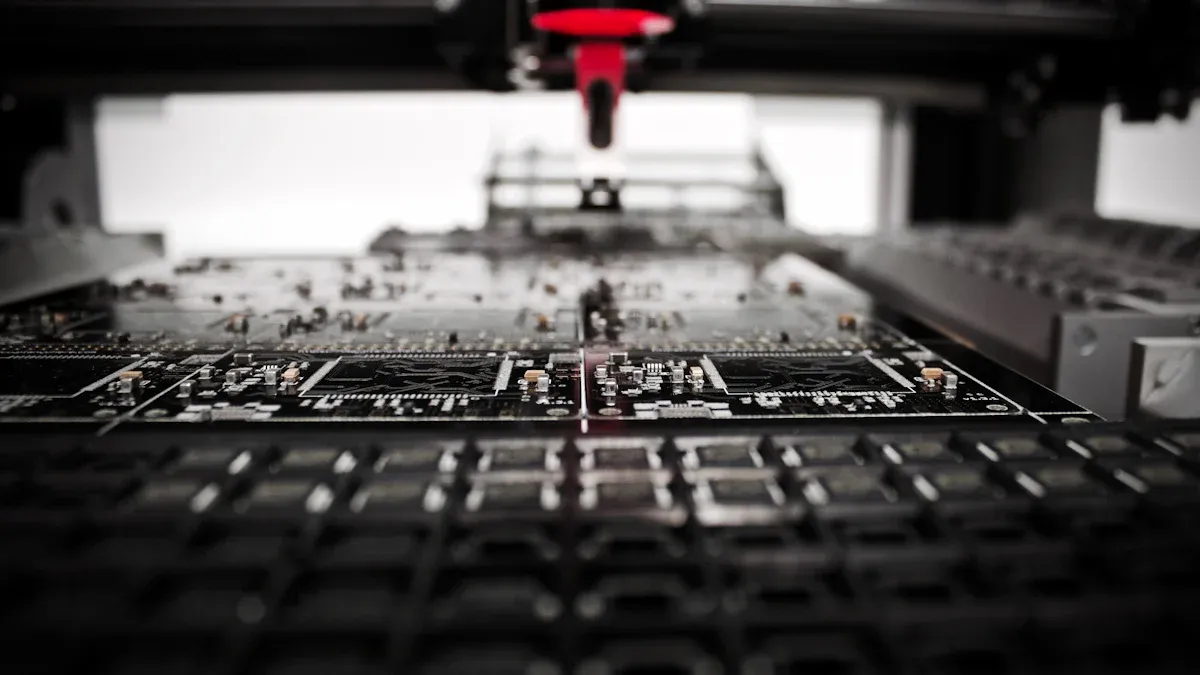

Quality Assurance Processes

You want your flex pcb boards to work well in cars. The best manufacturers use strict checks at every step. They follow rules and test boards many ways to make sure each one is safe and works right. Here is a table that shows good ways to check quality:

| Testing Method | Description |

|---|---|

| Electrical Testing | Checks that the flex pcb has no short or open circuits. |

| Mechanical Testing | Tests how well the board bends and flexes without breaking. |

| Environmental Testing | Makes sure the board works in heat, cold, and moisture found in vehicles. |

| Optical and Visual Inspection | Uses machines and people to spot defects or misaligned parts. |

| Industry Standards | Follows IPC-6013, IPC-T-50, IPC-A-600, and IPC-J-STD-003 for flex pcb testing. |

You should ask your supplier these questions: How do you test your flex pcb boards for cars? What rules do you follow? Can you show test reports for your boards?

Tip: If a supplier cannot answer these questions or show proof, you should see this as a warning sign.

Customization and Design Support

Every car project is different. You need a manufacturer who helps you from your first idea to the finished board. The best suppliers give strong design help and quick changes to fit your needs. They help you pick the right parts and make sure your flex pcb fits your car. Here is what you should look for:

| Aspect of Support | Description |

|---|---|

| Comprehensive Process | Guides you from idea to finished flex pcb design. |

| Custom Solutions | Makes special boards for high data rates or unique shapes in vehicles. |

| Component Selection | Helps you choose the best parts for your flex pcb and vehicles. |

| Quick Turnaround | Gives you samples and answers fast to speed up your project. |

You should ask: Can you help with custom flex pcb designs for cars? How fast can you make samples or changes? Do you give advice on picking parts for my project?

If a supplier cannot help with your design or takes too long to answer, you may have delays or problems in your cars.

Global Supplier Landscape

The world market for automotive flex pcb boards is growing quickly. More cars now use flex pcb for things like ADAS and electric power systems. Asia Pacific leads this growth, with many companies in China and Thailand making more boards. Europe also has strong companies, like Mektec, with sites in Berlin and across Asia.

Here are some key points about the world supplier market: Mektec is a big supplier with factories in Europe and Asia. China is now a leader in flex pcb making for cars. Thailand has a strong car industry and makes about two million cars each year.

New ways to design flex pcb help cars get lighter and smarter. New methods, like ultrasonic spraying, let companies make boards with very thin layers. This helps them make more boards and waste less. As more cars use electric power, the need for flex pcb in battery and control systems keeps growing.

When you pick a supplier, check their ability to make boards and their place in the world market. Ask about how many boards they can make and how they use new technology. The best suppliers spend money on research and use new ways to stay ahead.

Note: Picking a supplier with a strong world presence and advanced making helps you get good flex pcb boards for your cars, even as the market changes.

Making the Final Supplier Decision

Comparing Costs and Services

You have many options when picking an automotive FPC board supplier. You need to think about price, service, and quality. Each supplier is good at different things. Domestic suppliers often talk with you better. They help fix problems fast. You get your orders and answers quicker. But, you might pay more for workers. Overseas suppliers can save you money on big orders. But, it may take longer to get your boards. You could have shipping delays. You must think about these things to pick the best supplier for your needs.

| Factor | Domestic Suppliers | Overseas Suppliers |

|---|---|---|

| Cost | Higher labor costs | Lower costs for large volumes |

| Quality | Better communication and support | Potential logistical challenges |

| Lead Time | Faster shipping and response | Longer shipping times and delays |

You should ask suppliers what services they give. Do they help with technical problems? Can they send you samples? Will they help if you need to change your design? You want a partner who cares about quality at every step. Good service means you get help fast. This helps you avoid mistakes. Your project stays on schedule.

Tip: Ask for a list of all costs and services. This makes it easier to compare suppliers and spot hidden fees.

Balancing Quality and Lead Time

You need your automotive FPC boards to be high quality. You also want them made quickly. The best suppliers use new ways to do both. They can make boards up to 30% faster than normal. They use laser cutting and digital tools to check designs early. This saves time and money. They follow strict rules for quality. They build boards using ISO and IPC rules. They test every board with electrical checks, AOI, and reliability tests.

| Evidence Type | Description |

|---|---|

| Lead Time Reduction | Optimized processes cut lead time by up to 30% |

| Design Validation | Laser cutting and digital prototyping speed up early design checks |

| Quality Standards | Strict ISO and IPC standards ensure top quality |

| Testing Procedures | 100% electrical, AOI, and reliability testing for every board |

You should ask how suppliers keep quality high and lead time short. Do they use digital tools to check designs? Do they follow strict quality rules? Can they show you test results? You want a supplier who never picks speed over quality. You want boards that always meet car industry rules.

Note: The best suppliers spend money on research and new ideas. They keep making quality and lead time better. This helps you stay ahead in the car market.

You make a smart choice when you look at price, service, and quality. Pick a supplier who cares about quality like you do. You will get FPC boards that help your car projects do well.

Why Choose BESTFPC for your Auto Project?

When you pick a fpc manufacturer for your car project, you want someone who knows what you need. BESTFPC is different from other fpc manufacturer choices because you get more than just parts. You get help from experts, strong fpc connectors, and a team that helps you from the start to the end. There are many fpc manufacturer companies, but not many give you the same service and technology as BESTFPC.

You need a fpc manufacturer that follows strict rules. BESTFPC has IATF16949 approval and passes VDA checks. These show that this fpc manufacturer meets the highest quality needs. You can trust their fpc connectors in any car job. Many fpc manufacturer companies do not have these, so you take more risks with them.

BESTFPC gives you full help with design. You can share your idea, and this fpc manufacturer will help you make it real. Their team helps you pick the right fpc connectors for your plan. You get tips on layout, materials, and testing. Other fpc manufacturer choices may not help as much, so you might have to fix problems by yourself.

You want a fpc manufacturer with lots of experience. BESTFPC has over 20 years in electrical connection work. This means you get fpc connectors that last longer and work better. Many fpc manufacturer companies have less experience, so you might see more problems.

BESTFPC also lets you ask for special designs. You can get fpc connectors for fast data or special shapes. This fpc manufacturer works with you to meet your needs. Most fpc manufacturer companies only have basic designs, which may not fit your project.

Here is how BESTFPC compares to other fpc manufacturer choices:

| Feature/Service | BESTFPC | Competitors |

|---|---|---|

| Production Standards | IATF16949-approved and VDA-audited | Varies, not always certified |

| Design Support | Comprehensive support from idea to design | Limited support |

| Quality Assurance | High reliability for automotive applications | Varies, may not meet automotive standards |

| Experience | Over 20 years in electrical connection tech | Varies, often less experience |

| Customization | Tailored designs for high data rates | Standard designs, less flexibility |

| Connector Options | High quality from multiple brands | Limited options |

Tip: Pick a fpc manufacturer that spends money on research and new technology. This helps your fpc connectors stay up to date with new trends.

You want a fpc manufacturer who sends your order on time and helps you at every step. BESTFPC gives you peace of mind with strong fpc connectors and lots of skill. When you choose this fpc manufacturer, your car project has a better chance to do well.

You can pick the best automotive FPC board supplier if you do these things: First, look at their certifications and see if they follow quality rules. Next, check how much experience the supplier has and if they help you when you need it. Then, compare prices, how fast they deliver, and what services they give. Also, ask for reports that show their boards are tested and see if they help with design.

Remember: Doing good research keeps your project safe. Always use rules from the industry and trusted groups, like SAE International, to help you choose. Making smart choices means your car electronics will be safer and work better.

2026-01-05

2026-01-05

BEST

BEST

.png)

.png)

.png)

.png)

.png)