You want your project to turn out well, so picking the right flex PCB makers is very important. The flexible circuit board market is growing quickly. Check out these facts:

| Metric | Value | Timeframe |

|---|---|---|

| Market Size | USD 22.1 billion | 2022 |

| Projected Market Size | USD 48.7 billion | 2030 |

| Growth Rate (CAGR) | 10.5% | 2023-2030 |

| Leading Region | Asia Pacific | 2022 |

If you pick a flexible pcb supplier with good technical skills, your flexible electronic circuits will work better. Things like how many layers there are or what kind of plated holes are used can help your printed circuit board last longer. Top flex pcb makers like BESTFPC use these smart steps, so you get good quality every time. If you need flexible pcb help, the right company can help you do well.

Key Takeaways

- Picking the right flexible circuit board manufacturer helps your project work better and last longer.

- The best manufacturers use new machines and good materials to make strong and exact flexible circuit boards.

- Flexible circuit boards are used in many fields like medical, cars, planes, and electronics people use every day.

- You should pick manufacturers with good certificates, helpful customer service, and quick delivery.

- Talking clearly and planning early with your supplier helps stop delays and extra costs.

Top Flexible Circuit Board Manufacturers

Leading Global Companies

If you want the best flex pcb manufacturers, you should know who is on top. These companies are known for making high-quality flexible printed circuit boards. They have been working in this field for many years. They help big industries like cars, hospitals, and electronics.

Here is a table with some of the top flexible circuit board makers:

| Manufacturer Name | Location | What Makes Them Stand Out |

|---|---|---|

| Nippon Mektron | Japan | Global leader in flexible printed circuit modules for mobile, automotive, and robotics. |

| Zhen Ding Tech Group | Taiwan, China | Offers a wide range of flexible pcb and rigid-flex solutions worldwide. |

| Interflex | Korea | Specializes in flexible printed circuit and rigid-flex PCBs, with global production hubs. |

| Nitto Denko | Japan | Pioneer in flexible circuit board technology for many industries. |

| MFLEX | USA | Delivers integrated design and manufacturing for flexible pcbs. |

| Career Technology | Taiwan, China | Known for fast, versatile flexible pcb services across many markets. |

| Flexium | Taiwan, China | Focuses on green manufacturing and flexible printed circuit for wearables and medical devices. |

Tip: These flex pcb manufacturers have skilled teams and modern machines. You can count on them for big or tricky projects.

Notable Regional Flex PCB Manufacturers

You might also want to pick flex pcb manufacturers who are top in their area. These companies can save you money and deliver fast. They also know a lot about their local markets. In Asia-Pacific, there are many electronics companies and new ideas for flexible printed circuit. North America is great for cars and health care. Europe cares about green and high-quality flexible circuit board products.

- Asia-Pacific: Career Technology, Flexcom Inc, Daeduck GDS, Fujikura Ltd, Sumitomo Electric Industries, Interflex, Nitto Denko, NewFlex Technology, NOK Corp. These companies make flexible printed circuit for 5G, IoT, and tiny devices.

- North America: MFLEX is a leader in flexible printed circuit boards for cars and health care. AT&S is also good for medical technology.

- Europe: Companies here work on green flexible pcb and small designs. They help the airplane and car industries.

If you want your project to go well, look at both global and local leaders. They each have special skills. They help you get the flexible printed circuit that fits your needs.

Why These Flex PCB Manufacturers Stand Out

Technical Capabilities

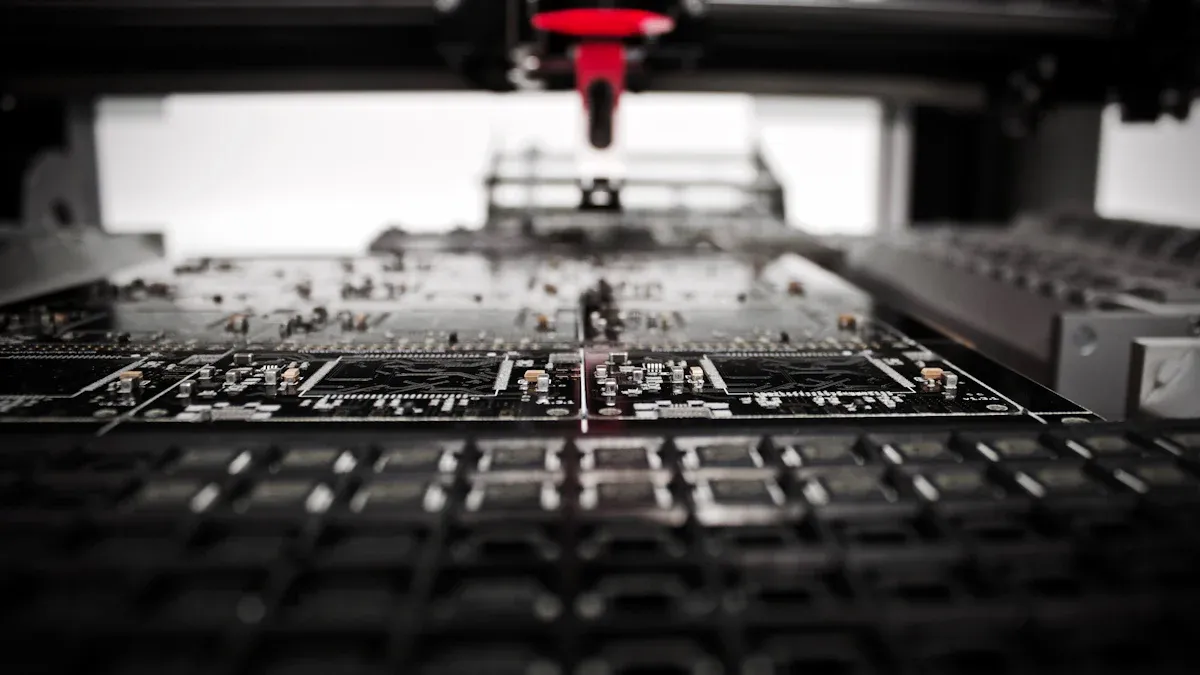

Top flex pcb manufacturers use very smart machines and tools. They make flexible printed circuit boards that fit what you need. Some tools they use are:

- Laser drilling machines make tiny, exact holes.

- Laminators help layers stick together well.

- Etching systems draw detailed circuit lines.

- Screen printing puts on neat solder masks.

- Laser cutters shape boards with sharp edges.

- Reflow ovens melt solder for strong joins.

- AOI systems find problems early.

- CNC routers cut boards into special shapes.

- Bonding machines glue layers tightly.

- Testing equipment checks if boards work right.

They use good materials like polyimide, polyester, and special laminates. These help flexible electronic circuits last longer and work better. Many flex pcb manufacturers can make hard designs, like multilayer or rigid-flex boards. They also help with fast things like 5G. Some can make big flexible printed circuit and add things like controlled impedance or heavy copper.

Quality and Certifications

You want your flexible printed circuit to be safe and strong. That is why top flex pcb manufacturers follow strict rules. They have certifications like ISO 9001 for quality, AS9100 for aerospace, and ISO 13485 for medical devices. These show the company cares about safety and doing things right.

- ISO 9001 checks every step for good quality.

- AS9100 adds more checks for airplane parts.

- ISO 13485 is for medical safety and rules.

- IPC and UL certifications make sure your flexible pcb is safe and works well.

These certifications help you trust your flexible electronic circuits. They will work in cars, planes, or hospitals.

Industry Applications

Flexible printed circuit boards are used in many places. You see them in medical devices, cars, planes, and gadgets. These boards need to bend, fit in small spaces, and handle heat or shaking. That is why flex pcb manufacturers make flexible electronic circuits that are strong, light, and work well.

- Medical: Used in implants and wearables.

- Automotive: Found in control systems and sensors.

- Aerospace: Used in avionics and satellites.

- Consumer electronics: Powering phones and smartwatches.

- Industrial: Used in robots and automation.

You can trust flexible printed circuit to keep working when things get hard. The right flexible substrate and design really matter.

How to Choose Flexible Circuit Board Partners

Picking the right company for your flexible printed circuit is important. The best partner will help your project do well. Here are some ways to find a good match.

Evaluating Technical Strengths

First, check what the manufacturer can really do. Look for these things:

- They follow IPC standards like IPC-A-600, IPC-6013, and IPC-2223.

- They use new machines, like laser direct imaging and AOI systems.

- They have strong quality checks, such as visual checks, X-ray, and electrical tests.

- They have certifications like ISO 9001:2015 and AS9100.

- They help with design, like DFM analysis and making samples.

- They test boards in real working places.

- They find problems early with careful checks.

If a company does these things, they can make good flexible printed circuit boards.

Assessing Customer Support

Good customer support makes your project easier. Some companies, like PCBANow, are known for great service. Here is what you should look for:

- Fast replies, sometimes in just a few minutes.

- 1-to-1 help all year long.

- High customer happiness.

- Teams that are professional and responsible.

- Long-term partnerships with clients.

Tip: Good support means you get help fast and avoid waiting.

Understanding Pricing Factors

Prices can be very different from one company to another. Here is a table to show what changes the price:

| Cost Factor | Description |

|---|---|

| Material Quality | Better materials cost more but last longer |

| Board Size | Bigger boards use more material and time |

| Number of Layers | More layers mean higher complexity and price |

| Board Finish | Extra finishes add to the cost |

| Hole Size | Smaller holes need special tools, raising the price |

| Trace and Space | Finer details require advanced processes |

| Thickness | Thicker boards are harder to make and cost more |

You should pick a manufacturer whose skills fit your project. Talking clearly and getting good help after buying can stop problems later.

Profiles of Top Flex PCB Manufacturers

Nippon Mektron, Ltd

Nippon Mektron is a leader in flexible circuit boards. They make lots of boards for phones, cars, and robots. Their team builds very thin and tiny circuits for small gadgets. They design fast and strong boards that last a long time. Their quality checks and shipping are quick and reliable.

| Aspect | Details |

|---|---|

| Main Product | Flexible Printed Circuits (FPCs) |

| Product Range | Single, double, multi-layer FPCs, automotive, wearable, robotics, high-frequency boards |

| Industry Applications | Automotive, consumer electronics, telecom, smart home |

| Innovation Focus | Fine-pitch, stretchable, and ultra-thin flexible circuits |

| Location | Tokyo, Japan |

Nippon Mektron uses green methods and works with top brands in medicine, cars, and electronics.

Viasion Technology Co., Ltd

Viasion Technology makes flexible printed circuits for many jobs. They do small and medium orders and let you pick your own design. Their team helps you from start to finish. You get fast prices, quick samples, and good support. Viasion works with car, medical, and factory companies. They have ISO 9001 and UL, so their boards are safe and good.

TTM Technologies

TTM Technologies gives you advanced flexible circuit boards. They make rigid-flex and semi-flex boards for tough work. Their boards are used in planes, defense, phones, and cars. TTM uses strong materials like polyimide and follows strict rules like IPC-6013D and ISO 9001. Their boards help with fast data, car safety, and electric cars. You can trust TTM for strong and steady boards.

- Rigid-flex and semi-flex boards

- Advanced joining and building

- ISO 9001, AS9100, and IPC certified

- Used in planes, defense, phones, cars, and data centers

Minco Products

Minco Products makes flexible circuit boards for important uses. They build single, double, and multilayer boards, plus rigid-flex types. You can add things like sensors or heaters to your board. Minco’s boards go into space shuttles, heart devices, and army gear. They have ISO 9001 and AS9100, showing they care about quality. You get kits and guides to help you design your board.

| Aspect | Details |

|---|---|

| Product Range | Single, double, multilayer, rigid-flex, integrated circuits with sensors or heaters |

| Key Strengths | High precision, repeatability, reliability |

| Notable Applications | Space, medical, defense, industrial |

| Certifications | ISO 9001:2000, AS9100B |

Sierra Circuits

Sierra Circuits gives you flexible boards with many choices. You can pick single, double, or multilayer boards and choose copper thickness. They use good materials like polyimide and epoxy. Sierra’s factory has new machines for SMT, thru-hole, and mixed tech. You get fast building, testing, and even help with software. They have ISO 9001:2015, AS9100D, ISO 13485, and ITAR. Sierra helps plane, medical, and tech companies who need fast, good boards.

- Custom thickness and materials

- Advanced building and testing

- Full certifications for planes and medical

JLCPCB

JLCPCB is great if you want fast, cheap samples and small orders. Their factories use robots to keep prices low and quality high. You can order boards online and track your order easily. JLCPCB helps many fields, from gadgets to factory controls. They give 24/7 help and ship quickly all over the world.

BESTFPC

BESTFPC makes flexible boards for hard jobs. You will find their boards in planes, medical tools, and gadgets.

| Industry | Applications and Benefits |

|---|---|

| Aerospace | Light, high-temp boards for planes and space |

| Medical Devices | Small, bendy boards for implants and wearables |

| Consumer Electronics | Rigid-flex boards for thin phones, tablets, and gadgets |

BESTFPC gives you custom boards, heat resistance, and steady work. Their team helps you meet tough rules.

AT&S

AT&S is known for medical and high-tech boards. You get flexible boards with tiny lines and strong parts. Their EN ISO 13485 means their boards are safe for medical use. AT&S uses rolled copper and special coatings for long life. Their 2.5D tech makes boards thin and light, good for wearables and implants.

| Certification / Strength | Description |

|---|---|

| EN ISO 13485 | Medical device safety and reliability |

| Miniaturisation and HDI Technology | Ultra-small tracks, stacked vias |

| Flexible Base Materials | Rolled copper for high bending cycles |

| Special Surface Treatments | Carbon print for durability |

| 2.5D Technology | Thinner boards for compact devices |

| R&D Focus | Leading innovation in Europe |

Epec Technologies

Epec Technologies works with you to make custom flexible boards for many fields. They help the army, planes, power, and green energy. Epec listens to what you need and follows local rules. They have ITAR and other certifications, so their boards are safe for special uses. Epec offers flex and rigid-flex boards, cables, and engineering help.

| Industry Sectors Served | Product and Service Offerings |

|---|---|

| Military and Aerospace | Flex & Rigid-Flex PCBs, Cable Assemblies, Printed Circuit Boards |

| Electronics Manufacturing | CNC Machining, User Interfaces |

| Power Electronics | Flexible Heaters, EC Fans & Motors |

| Renewable and Sustainable Energy | Customized engineering solutions, quality assurance, global operations |

Northpoint Technologies, Inc.

Northpoint Technologies makes custom flexible circuits for many jobs. They build single, double, and multilayer boards. Their team helps you from idea to delivery, making sure you get what you want. Northpoint uses smart tricks like nesting, service loops, and thin copper for bendy boards. You get good quality, fair prices, and on-time shipping. They help car, medical, army, plane, phone, oil, and more. Northpoint has factories in the USA, Mexico, and China.

- Custom designs and close help

- Advanced building for bendy and strong boards

- Full assembly and testing

RUSHPCB UK

RUSHPCB UK helps you get strong flexible boards fast. Their engineers work with you on design and testing. They have ISO 9001 and ISO 13485, so their boards are safe and good. Customers like their samples and quick work. RUSHPCB UK does everything from design to building and testing.

- Careful quality checks

- Fast samples and shipping

- Trusted by clients for steady results

Best FPC

Best FPC has over 16 years making flexible boards. You can order rigid-flex, multilayer, and special boards without outside help. Their factory has over 160 workers and makes 28,900 square meters each month. Best FPC helps over 3,000 clients in more than 60 countries. They have UL, ISO13485, ISO9001, and RoHS. You get careful checks, fast shipping, and custom boards for medical, car, and phone uses.

| Strength/Certification Aspect | Details |

|---|---|

| Certifications | UL, ISO13485, ISO9001, RoHS |

| Industry Experience | 16+ years, 3,000+ clients, 60+ countries |

| Manufacturing Capabilities | Rigid-flex, multi-layer, special FPCs |

| Delivery Performance | 97.2% on-time delivery |

| Application Strengths | Medical, automotive, communication electronics |

PCB Power

PCB Power gives you flexible boards for many fields. You will see their boards in medical tools, cars, planes, and robots. PCB Power’s boards are small, light, and strong. They can handle shaking and heat, so your devices work in hard places.

| Industry | Application Examples | Reasons for Using Flexible PCBs |

|---|---|---|

| Medical | Endoscopes, monitors, hearing aids, sensors | Mini size, handles movement and cleaning |

| Automotive | Dashboards, LED lighting, driver help | Handles shaking, fits curved spaces |

| Aerospace | Aircraft, satellites | Light, works in tough places |

| Industrial | Robots, automation | Handles motion, resists stress |

| Lighting | LED systems | Good heat transfer, uses little power |

| eCommerce | Portable warehouse devices | Easy to carry, lasts in rough places |

WellPCB

WellPCB helps you from design to shipping with flexible boards. They have seven factories and three sales offices worldwide. You get help at every step, from samples to big orders. WellPCB uses high-tech printing and laser tools for exact boards. They use new materials like composites and graphene. Over 4,000 customers trust WellPCB for fast, expert help and custom boards.

- Global factories and sales

- New tech for small boards

- Full service and strong support

Saturn Flex Systems

Saturn Flex Systems has over 30 years of experience. They make multilayer flexible and rigid-flex boards for army, planes, medical, and business. Saturn Flex builds boards for hard jobs, like body implants and radio systems. You can use their boards in phones, doors, lights, and cars.

- Experts in tough and special jobs

- Trusted for working in hard places

ASC

ASC is known for many certifications and special ways of making boards. You get flexible boards that meet army, plane, medical, and car rules. ASC uses special plating and heating for better boards. Their own thermal materials help control heat. ASC uses careful checks and machines to make sure every board is right.

| Certification / Process | Description |

|---|---|

| MIL-PRF-31032 | Army standard for flexible, rigid, and rigid-flex boards |

| AS9100 Rev D | Plane quality management |

| ISO 9001:2015 | Quality management system |

| ISO 13485:2016 | Medical device quality |

| IATF16949:2016 | Car quality |

| ITAR Registration | U.S. defense rules |

| Tin Lead Plating | Better plating process |

| Hot Oil Reflow | Special heating for army/planes |

| Patented Thermal Materials | Custom heat control |

Hitech Circuits Co., Ltd

Hitech Circuits Co., Ltd gives you flexible boards for phones, gadgets, medical, and cars. They offer samples, building, assembly, and design help. Hitech uses new machines and a skilled team to make custom boards fast. You get help all day and night and help with layout and design. Hitech can make flexible, rigid-flex, RF, microwave, and ceramic boards, with up to 38 layers and thick copper.

| Aspect | Details |

|---|---|

| PCB Types | Flexible, rigid-flex, RF, microwave, ceramic |

| Manufacturing Capacity | Up to 38 layers, heavy copper, HDI, high-speed |

| Services | Design, samples, assembly, reverse engineering |

| Industries Served | Gadgets, LED, medical, cars, phones, new energy, chips, factories |

| Technical Strengths | 100+ design projects/year, 10+ years experience, 24/7 help |

Flexible Electronic Circuits in Industry

Medical Applications

Flexible electronic circuits are used in many medical tools. Doctors and patients get new ways to check health. For example, a heart monitor can bend with your body. Some patches stick to your skin and watch your health all day. Hospitals use these circuits in imaging machines and hearing aids. These circuits fit in small spaces and move with you. This gives you more comfort and keeps you safe.

Note: Flexible circuits can handle cleaning and high heat, so they are good for hospitals.

Aerospace and Military Uses

Planes, satellites, and military gear use flexible electronic circuits. These circuits help save space and make things lighter. This is very important when flying. They can handle shaking, heat, and cold. You might see them in cockpit controls or radar systems. Soldiers use gear with these circuits because they last long and do not break easily. Engineers trust them for missions that must not fail.

- Lighter weight for aircraft

- Strong against vibration and shock

- Reliable in extreme weather

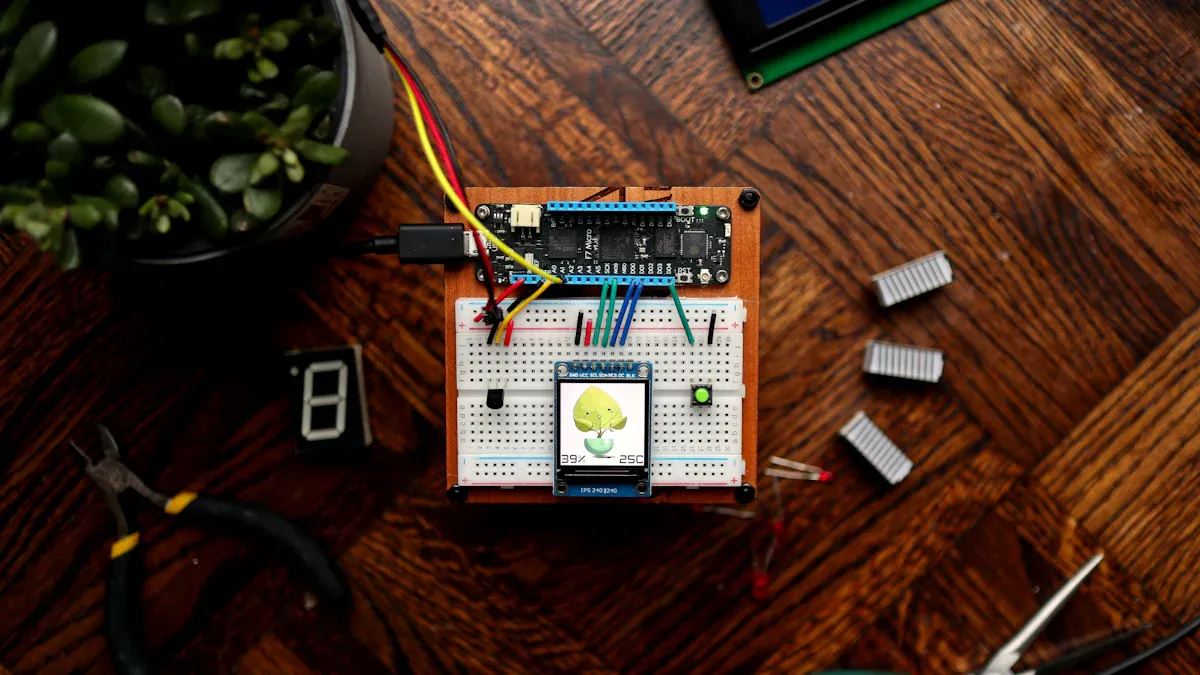

Consumer Electronics

You use flexible circuits every day, even if you do not notice. Your smartphone, smartwatch, and headphones have these small, bendy boards. They help make devices thinner and lighter. Some gadgets can fold or twist because of these circuits. Game controllers, cameras, and fitness trackers use this technology too. You get more features in smaller devices.

| Device Type | How Flexible Circuits Help |

|---|---|

| Smartphones | Thinner, lighter, more durable |

| Wearables | Bend and fit your wrist or body |

| Cameras | Fit into small, moving parts |

Common Concerns with Flex PCB Manufacturers

Cost and Customization

Flexible circuit boards usually cost more than regular ones. This is because they need special materials and machines. If you want a custom design, the price can go up. More layers or special shapes also make it cost more. You might pay extra for samples or small orders.

Some things change the price:

- Rolled annealed copper costs more but bends better

- More layers and bigger boards cost more

- Special finishes or coatings add to the price

- Custom shapes or tight bends can raise costs

To save money, talk to your manufacturer early. Tell them what you need and ask for tips. Many companies help you pick good materials and designs. This can stop extra costs. Good planning helps you avoid mistakes and expensive changes later.

Lead Times and Delivery

Getting your flex PCBs on time is very important. Delays can slow down your project. Sometimes, there are problems getting parts or materials. These problems can make delivery late.

You can lower these risks by:

- Talking often with your suppliers

- Using more than one supplier for important parts

2025-07-28

2025-07-28

BEST

BEST

.png)

.png)

.png)

.png)

.png)