You want a great display for your project. COF/COG FPC is good for new displays. It gives you lots of flexibility. It is thin and keeps signals strong. COF is good when you need flexible wires. It is easy to put in. COG gives you clear pictures. It also lets you touch the screen fast. Think about your money, space, and what you need. This helps you choose the best technology.

Key Takeaways

- COF works well for bendable and curved devices. COG gives better picture and touch for flat screens.

- Flexible printed circuits help make devices thin and light. This makes phones, tablets, and wearables work better and last longer.

- Picking the right base material is very important. Polyimide is good for fancy displays. Polyester is better if you want to save money.

- Think about how easy it is to install, the price, and how well it works. This helps you choose between COF, COG, and FPC for your device.

- Best FPC gives expert help and fast samples. They help you build strong connections for new electronics.

Understanding the Fundamentals: What are COF and COG FPC?

When you pick a display, you should know how COF/COG FPC works. These solutions help your device work better. They also make devices thinner and more reliable. You can find them in phones, tablets, cars, and medical tools.

COF (Chip-on-Flex) vs. COG (Chip-on-Glass): Key Differences

Modern displays use COF or COG. Each one is different and has its own benefits.

| Feature | COF (Chip-on-Flex) | COG (Chip-on-Glass) |

|---|---|---|

| Flexibility | High | Low |

| Cost | Moderate | Lower for large volumes |

| Installation | Easy in tight spaces | Needs precise alignment |

| Display Quality | Good | Excellent |

| Touch Performance | Good | Superior |

-

COF (Chip-on-Flex):

The driver IC goes right on a flexible printed circuit. This makes it easy to bend or fold. It fits well in small or curved places. You see COF in smartwatches, foldable phones, and car dashboards. -

COG (Chip-on-Glass):

The driver IC is put right on the glass of the display. This makes the display very thin and gives great picture quality. COG is used in screens that need sharp images and fast touch.

Tip: Pick COF for curved or bendy devices. Pick COG if you want the best picture and touch.

Why Flexible Printed Circuits (FPC) are Critical for IC Packaging

Flexible printed circuits help connect chips in small spaces. FPCs make devices thinner, lighter, and stronger. They can bend and twist without breaking. They also keep signals strong and reduce interference.

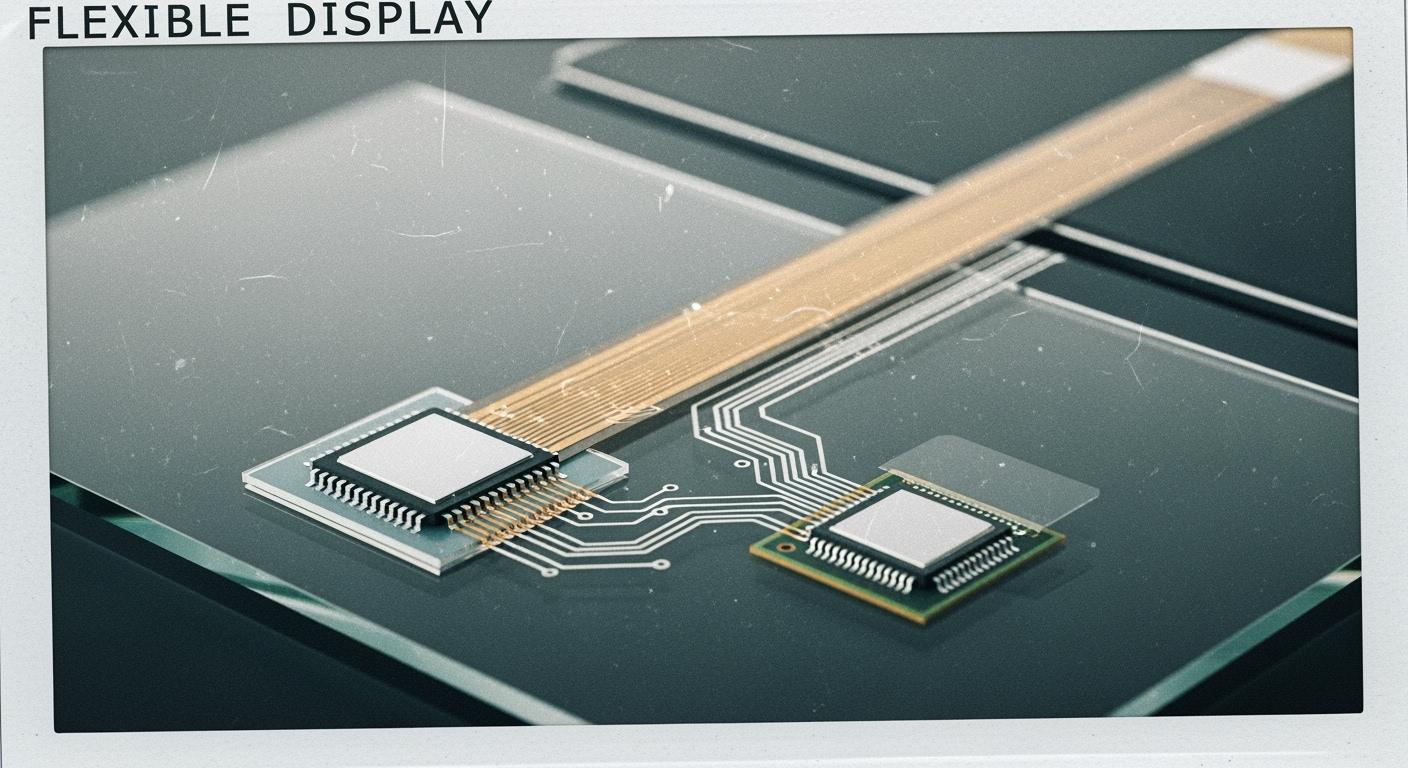

Structural Components of a High-Precision COF Assembly

A high-precision COF assembly has several main parts:

-

Flexible Substrate:

Polyimide or polyester film is used as the base. This material bends easily and does not get damaged by heat. -

Copper Traces:

These tiny lines move signals from the chip to the display. -

Driver IC:

The integrated circuit is placed right on the flexible base. -

Bonding Pads:

These spots let you connect the COF to the display or other parts. -

Protective Layer:

A coverlay or solder mask is added to keep the traces safe.

This setup gives you a small, light, and strong connection. COF/COG FPC technology helps meet the needs of today’s electronics.

Note: Always pick the right technology for your project. Think about how flexible, costly, or easy to install it is before choosing.

Technical Specifications and Manufacturing Capabilities at Best FPC

You want your display to work really well. Best FPC gives advanced solutions for COF/COG FPC. These solutions meet tough industry rules. You can trust their skills with fine pitch, picking materials, and surface finishes.

Fine Pitch Requirements: Navigating the Challenges of Ultra-Thin Traces

Ultra-thin traces are needed for sharp displays. Fine pitch technology lets you fit more connections in less space. Best FPC can make traces as thin as 30μm. This helps stop signal loss and makes the display look better. You get steady performance in phones, tablets, and car screens.

Tip: Use fine pitch FPC for devices that need clear images and quick touch.

Base Materials: Polyimide (PI) vs. Polyester (PET) in High-End FPC

You have to pick the right base material for your project. Polyimide (PI) and polyester (PET) are the main choices.

| Material | Flexibility | Heat Resistance | Cost | Typical Use |

|---|---|---|---|---|

| Polyimide | High | Excellent | Higher | Premium displays, COF |

| Polyester | Moderate | Good | Lower | Cost-sensitive applications |

Polyimide bends better and handles heat well. Polyester is cheaper and works for less tough jobs.

Achieving Sub-30μm Pitch in COF Manufacturing

You can get sub-30μm pitch with new COF manufacturing. Best FPC uses careful etching and lamination steps. This helps make high-density connections for new displays. You get small designs that still work well.

Surface Finish Options: ENEPIG, ENIG, and OSP for Enhanced Reliability

A good surface finish keeps your FPC safe. Best FPC has several choices:

- ENEPIG: Great for wire bonding and stops rust.

- ENIG: Makes a smooth surface and is easy to solder.

- OSP: Saves money and is good for simple designs.

Note: Pick the surface finish that fits your device’s needs and where it will be used.

You can count on Best FPC for COF/COG FPC solutions that meet your needs.

Major Applications: Where COF and COG FPC Drive Innovation

Consumer Electronics: Smartphones, Tablets, and Wearables Integration with Display Panels

COF/COG FPC technology is in most new devices. Smartphones use these circuits to keep screens thin and bright. Tablets need strong connections for touch and clear pictures. Wearables, like smartwatches, need flexible circuits that bend easily. These circuits help devices use less space and weigh less. You get longer battery life and lighter gadgets.

Tip: Use flexible circuits when you design new devices. This makes them last longer and work better for users.

Automotive Display Systems: The Shift to Curved OLED Dashboards

Car makers use curved OLED dashboards for style and more info. COF/COG FPC connects these screens to the car’s computer. These circuits handle shaking and heat inside cars. You get good performance even when driving is rough. Flexible circuits let designers make new shapes for dashboards.

Medical Devices: High-Density Interconnects for Diagnostic Equipment

Medical tools must be small, light, and work well. COF/COG FPC is in monitors and diagnostic machines. These circuits fit lots of connections in tiny spaces. Signals stay strong, so doctors get clear results. Flexible circuits also make cleaning and fixing devices easier.

Industrial IoT and Smart Home Integration

Factories and smart homes have many connected devices. Reliable circuits keep sensors and displays working together. COF/COG FPC helps move data fast and keeps signals strong. You can put these circuits in tight or curved places. This helps build smarter homes and factories.

Note: Flexible circuits help new technology work better in every area.

Frequently Asked Questions (FAQ) About COF FPC

What is the typical lead time for custom COF FPC design?

You want your project to finish fast. Most custom COF FPC designs need 2 to 4 weeks. This is from the idea to getting a sample. The time changes if your design is hard or has more layers. If you pick special features, it might take longer. You can help things go faster by giving clear drawings and needs to your supplier.

Tip: Ask for a full project plan before you begin. This helps you get ready and stop delays.

Can COF technology support 4K and 8K display resolutions?

COF technology works for high-resolution screens. It supports 4K and 8K panels. COF handles fine pitch and lots of connections. You get clear pictures and quick touch. Makers use COF in top TVs, tablets, and monitors. You should look at your display specs and check if COF/COG FPC fits your resolution.

| Resolution | Supported by COF | Typical Use Cases |

|---|---|---|

| 4K | Yes | TVs, tablets, laptops |

| 8K | Yes | High-end monitors, TVs |

How do environmental factors affect the bonding reliability of COG?

You need to think about the environment when using COG. High humidity, heat, and dust can make the bond weak. This can cause signal loss or display problems if things are rough. Makers use special glue and coatings to make things stronger. You should keep and use your devices in clean, dry places for best results.

Note: Always ask your supplier about how COG handles the environment. This helps you stop problems later.

Conclusion: Partner with Best FPC for High-Performance Interconnects

You want your display project to do well. Picking the right interconnect is important. COF FPC, COG FPC, and flexible printed circuits have special strengths. COF FPC bends for curved or small devices. COG FPC gives clear images and fast touch for fancy screens. Flexible printed circuits save space and make devices work better.

Think about these things before you choose:

- Budget: COF FPC costs more but works for cool designs. COG FPC is good for lots of products and saves money.

- Flexibility: COF FPC bends and folds for wearables and car dashboards. COG FPC is best for flat, thin screens.

- Performance: COG FPC gives great picture and quick touch. COF FPC keeps signals strong in hard places.

- Installation: COF FPC is easy to put in small spots. COG FPC needs careful setup but looks smooth.

| Technology | Best For | Main Benefit | Limitation |

|---|---|---|---|

| COF FPC | Curved, flexible devices | High flexibility | Higher cost |

| COG FPC | Flat, high-res displays | Superior quality | Less flexible |

| FPC | All electronics | Space saving | Needs careful design |

Tip: Pick the technology that fits your device. This helps your product last longer and work better.

Best FPC helps you with COF and COG FPC solutions. You get help from experts, fast samples, and strong products. You can talk to Best FPC for custom designs, help, and quick prices. You make your display better and stay ahead.

Want a better display? Contact Best FPC now. You get strong interconnects for new electronics.

You have to pick COF, COG, or FPC for your display. Each one is good at something and has a downside. COF bends easily and fits in small spaces, but it costs more. COG gives sharp images and fast touch, but it does not bend much. FPC saves space, but you must plan how to use it.

| Technology | Strengths | Weaknesses |

|---|---|---|

| COF | Flexibility, fit | Higher cost |

| COG | Image, touch speed | Less flexible |

| FPC | Space saving | Needs planning |

Tip: Pick COF if your device is curved. Pick COG for screens that need great pictures. Pick FPC for small devices. The best choice helps your product work well and be worth more.

FAQ

What is the typical lead time for custom COF FPC design?

You get custom COF FPC samples in 2 to 4 weeks. The time depends on how hard your design is. It also depends on what materials you pick. If you give clear drawings, things go faster. If you say what you need, it helps production move quickly.

Can COF technology support 4K and 8K display resolutions?

COF FPC works for 4K and 8K displays. This technology handles fine pitch connections well. It also supports high-density links. You see sharp images on these screens. Touch response is quick for advanced displays.

How do environmental factors affect the bonding reliability of COG?

Keep COG FPC safe from humidity, heat, and dust. These things can make the bond weak. They might cause problems with your display. Makers use special glue and coatings to help. This makes flexible printed circuits work better.

What surface finishes are best for COF and COG FPC?

Pick ENEPIG if you need wire bonding. Choose ENIG for smooth soldering jobs. OSP is good if you want to save money. Each finish helps your display work well. They also make your device more reliable.

Tip: Ask your supplier which finish is best for your device and where you use it.

2025-12-22

2025-12-22

BEST

BEST

.png)

.png)

.png)

.png)

.png)