Have you ever wondered how your favorite gadgets come to life? Understanding essential concepts in electronic manufacturing gives you the foundation to turn ideas into real devices. You will see how a pcb connects components and enables signals to flow. This guide makes complex processes simple, so you can start your journey with confidence.

Key Takeaways

- Understand the electronic manufacturing process from design to delivery. Each stage has unique tools and technologies that ensure quality and efficiency.

- Master the basics of printed circuit boards (PCBs). They connect components and are crucial for the functionality of electronic devices.

- Focus on Design for Manufacturing (DFM) principles. Simplifying designs and standardizing components can reduce errors and improve production efficiency.

- Prioritize testing and inspection throughout the manufacturing process. Early detection of defects saves time and resources, ensuring product reliability.

- Leverage electronic manufacturing services (EMS) providers. They offer expertise and resources that can accelerate your product development and improve quality.

Electronic Manufacturing Overview

What Is Electronic Manufacturing

You step into the world of electronic manufacturing when you bring circuits to life. This field covers the entire journey from designing circuits to delivering finished products. You start with a concept, then use specialized tools to create and test circuits. The process involves several key stages, each with its own tools and technologies:

| Stage | Tools / Technologies | Brief Description |

|---|---|---|

| Design & Prototyping | EDA tools (Altium, Eagle), manual soldering | Define functions, electrical connectivity, and structure; validate initial feasibility |

| Component Sourcing | ERP systems, Digi-Key, Mouser | Ensure component quality and delivery; avoid supply shortages |

| PCB Fabrication | CNC drilling, plating line, OSP/ENIG process | Produce high-quality PCBs per design, including rigid, flex, or rigid-flex types |

| PCB Assembly (PCBA) | Pick-and-place, insertion machines, reflow ovens | Accurately and efficiently mount components onto circuits |

| Soldering Process | Reflow oven, wave soldering, solder paste printer | Establish electrical connections and ensure soldering reliability |

| Testing & Quality Control | AOI system, ICT fixtures, programmers, burn-in chambers | Verify electrical performance and screen for potential defects |

| Final Assembly & Packaging | Electric screwdrivers, heat shrink, packing tools | Complete full product integration and prepare for shipment |

Industry standards organizations, such as ISO and IEC, set guidelines for data, interoperability, and quality in electronic manufacturing. These standards help you ensure that circuits meet global requirements for safety and performance.

Why It Matters

Understanding electronic manufacturing gives you a clear view of how circuits power modern technology. You need to know each step to design reliable circuits and avoid costly mistakes. Real-time visibility into the process helps you optimize production and maintain quality. Material management prevents line stoppages and ensures that circuits receive the right components at the right time.

Tip: Complete traceability is essential for industries like automotive and aerospace, where every circuit must meet strict regulatory demands.

The electronic manufacturing industry continues to grow, driven by demand for consumer electronics and IoT devices. You can expect this market to expand at a steady pace, offering new opportunities for those who master the basics of circuits and manufacturing.

PCB and Components

Printed Circuit Board Basics

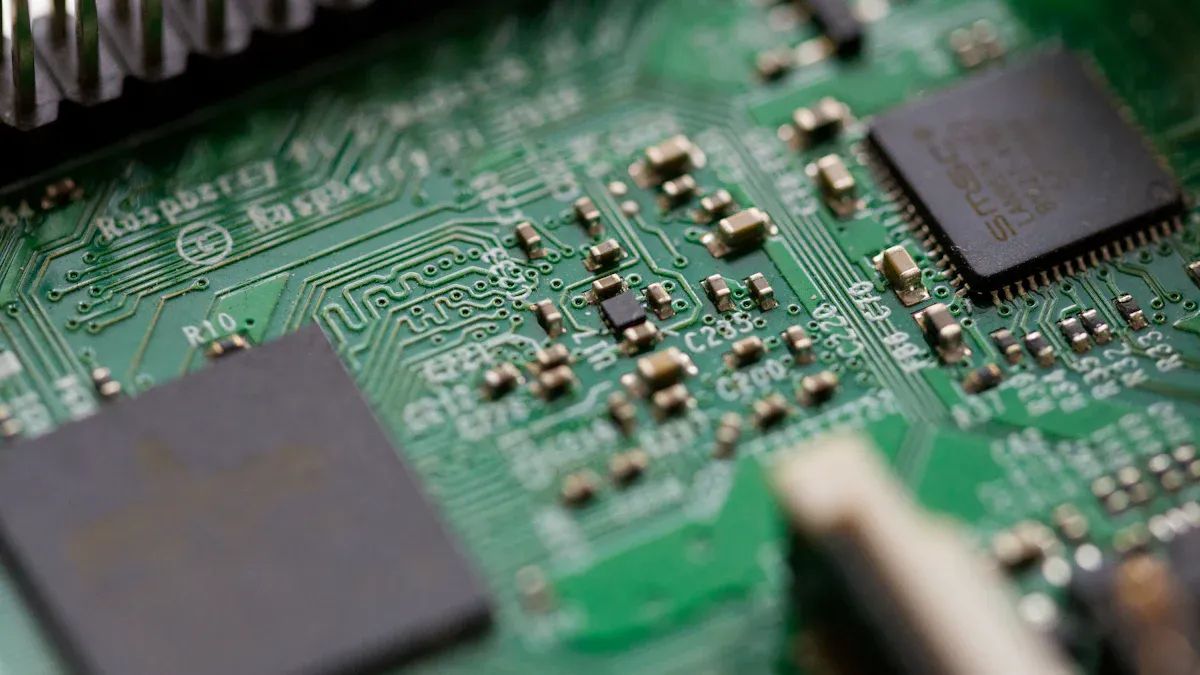

You rely on the pcb as the foundation of every electronic device. The printed circuit board connects all circuit board components, allowing them to work together. When you look at circuit boards, you see a network of copper traces and pads. These traces act as highways for electrical signals and power. The pcb also provides mechanical support, holding circuit board components in place and protecting them from damage.

- PCBs connect electronic components, making sure each part communicates with others.

- They distribute power and signals across the device, ensuring everything functions as designed.

- Printed circuit boards serve as the backbone, giving structure and stability to circuit board components.

You will find that every modern device, from smartphones to washing machines, depends on the reliability of its pcb. When you design or assemble circuit boards, you must pay attention to layout and quality. A well-designed pcb prevents signal loss and reduces the risk of malfunction.

Essential Electronic Components

You build every electronic device using a set of basic electronic components. These parts each play a unique role on circuit boards. Understanding their function helps you troubleshoot and design better systems.

- Resistors

- Capacitors

- Transistors

- Switches

- Diodes

- Motors

- Potentiometers

Capacitors store and release electrical energy. Resistors limit current flow and dissipate power as heat. The physical proximity of these components on the pcb determines how they interact.

The humble resistor, with its simple design and profound purpose, regulates current in electronic circuits. It acts as a bottleneck, creating a voltage drop that controls the flow of current, much like a valve adjusting water flow.

Transistors stand as the gatekeepers of electronic circuits. They act as switches that control the flow of electronic signals. Their operation resembles a water valve, where a small signal commands a larger current.

You will see these circuit board components on almost every pcb. When you understand how each part works, you can create more reliable and efficient circuit boards. Mastering the basics of electronic components and their placement on the pcb sets the stage for successful projects.

Manufacturing Process Guide

The manufacturing process for a pcb involves several critical steps. You must understand each stage to ensure reliable circuit board assembly and high-quality production. This guide walks you through the journey from pcb design to final inspection, highlighting best practices and common pitfalls.

Design for Manufacturing (DFM)

You begin every successful pcb manufacturing process with strong pcb design principles. Design for Manufacturing (DFM) helps you create layouts that simplify assembly and reduce errors. Early consideration of manufacturing processes leads to fewer redesigns and smoother production.

| Principle | Description |

|---|---|

| Simplification | Reduce the number of components to simplify design and assembly. |

| Standardization | Use standard parts and materials to lower costs and improve consistency. |

| Assembly Optimization | Optimize the assembly process for efficiency and easy access to components for testing. |

| Quality Control Integration | Integrate quality control measures throughout the manufacturing process. |

- Simplify product design to minimize assembly steps.

- Standardize components to streamline sourcing and assembly.

- Optimize material usage to reduce waste.

- Integrate quality control at every stage.

Tip: Address manufacturability early in pcb design. This approach prevents costly delays and ensures your printed circuit board meets industry standards.

Common design errors can disrupt pcb manufacturing. Watch for misaligned pin numbering, inadequate clearance between pads, and poor via design. Ignoring thermal considerations or neglecting power and ground plane layouts can cause overheating and signal issues. Always align your pcb layout and design with manufacturer capabilities to avoid delays and extra costs.

PCB Fabrication Steps

The pcb fabrication process transforms your digital design into a physical board. Each step in pcb fabrication requires precision and attention to detail.

- Select the base material, usually FR4.

- Clean the copper-clad panel to remove contaminants.

- Apply a light-sensitive material and expose it to UV light to transfer the pattern.

- Etch away unprotected copper using a chemical solution.

- Stop the chemical reaction and remove the remaining photoresist.

- Drill holes for interlayer connections and components.

- Apply a thin copper layer for internal connectivity.

- Coat the board with a solder mask to protect copper traces.

- Print a silkscreen layer for labels and symbols.

- Apply a solderable finish to exposed copper pads.

- Test the board for electrical defects.

- Conduct visual inspection and final cleaning.

- Package the board for transport.

You can expect an average yield rate of about 95% in pcb fabrication. A first pass yield above 90% is acceptable for most projects. High yield rates depend on careful panel design and strict process control.

Parts Sourcing

Reliable parts sourcing forms the backbone of every pcb manufacturing process. You must ensure that all components meet quality standards and are available when needed.

- Check that parts meet high standards to avoid failures and safety hazards.

- Confirm availability in required quantities and order early to prevent delays.

- Verify compliance with industry standards for safety and reliability.

- Choose suppliers who offer strong warranties and technical support.

- Consider long-term costs, not just upfront prices.

You can use X-ray and electrical testing to verify parts. Cross-reference components with electronic tools like Octopart. Submit a complete bill of materials (BOM) to trusted suppliers for sourcing assistance.

Supply chain disruptions can impact your production. Global semiconductor shortages, logistical bottlenecks, and market volatility may delay parts delivery. Natural disasters and pandemics can also disrupt manufacturing processes. Plan ahead and maintain good relationships with suppliers to minimize risks.

PCB Assembly Methods

You have several options for pcb assembly, each with unique advantages. The right method depends on your design and production needs.

| PCB Assembly Method | Advantages |

|---|---|

| Surface Mount Technology | Reduced board size, higher component density, lower production costs for large-scale runs |

| Through-Hole Technology | Robust mechanical bonds, high durability, resistance to heat and stress |

| Mixed Technology | Flexibility in design, accommodates both compact layouts and heavy-duty connections |

Surface mount technology (SMT) allows you to place components directly onto the pcb surface. This method supports high-density layouts and fast production. Through-hole technology provides strong mechanical bonds, making it ideal for components that face stress or heat. Mixed technology combines both approaches for maximum flexibility.

Panel design plays a crucial role in pcb assembly. Good panel design improves production efficiency and reduces defects. Arrange multiple boards on a single panel to streamline circuit board assembly and minimize waste.

Testing and Inspection

Testing and inspection ensure the reliability of every pcb before it leaves the factory. You must use a combination of automated and manual techniques to catch defects early.

- Automated Optical Inspection (AOI) uses high-resolution cameras to check for defects in circuit board assembly.

- X-ray inspection reveals hidden issues in multilayer pcbs and BGA components.

- Automated Visual Inspection (AVI) verifies correct component placement and detects visible defects.

- Solder Paste Inspection (SPI) checks solder paste application before component placement.

- Functional testing equipment simulates real-world conditions to verify circuit performance.

Each method targets specific stages of the manufacturing process. AOI and SPI focus on early detection, while functional testing ensures the finished product works as intended. Consistent inspection throughout pcb manufacturing reduces rework and boosts reliability.

Note: Integrate testing and inspection into every stage of the manufacturing process. Early detection of defects saves time and resources in later production steps.

By following these steps and focusing on panel design and assembly techniques, you can achieve reliable, high-yield pcb manufacturing. Mastering each stage of the manufacturing process sets the foundation for successful circuit board assembly and long-term product quality.

Electronic Manufacturing Services

EMS Providers

You rely on electronic manufacturing services (EMS) providers to bring your electronic products from concept to reality. These companies specialize in a wide range of services that support every stage of the manufacturing process. EMS providers help you manage complex projects and ensure your assemblies meet industry standards.

- PCB assembly: Building the essential circuit boards for your devices.

- System assembly: Creating complete electronic products ready for the market.

- Testing and quality control: Verifying that your products function reliably.

- Logistics and distribution: Handling delivery and returns efficiently.

- Prototyping services: Allowing you to test concepts before full-scale production.

- Box build assembly: Completing the final assembly of complex products.

- Component sourcing: Securing reliable parts for your manufacturing needs.

- Test solutions: Ensuring performance and quality through rigorous checks.

- After-sales support: Managing repairs and customer service.

- System integration: Making sure all components work together seamlessly.

EMS providers play a vital role in the electronic manufacturing industry. They help you focus on innovation while they handle the technical details.

Roles and Benefits

When you partner with an EMS provider, you gain access to advanced manufacturing expertise. These companies streamline your production processes and help you reduce time-to-market for new electronic products. You benefit from collaborative design, which improves manufacturability and cost-effectiveness. EMS partners support you with swift iterations, so you can respond quickly to market changes.

- EMS providers accelerate product development and manufacturing timelines.

- Their experience in custom cable assembly and system integration ensures your assemblies meet high standards.

- You stay competitive by leveraging their knowledge and resources.

Tip: Working with an EMS provider allows you to focus on your core business while experts handle the technical challenges.

Choosing EMS

Selecting the right EMS partner requires careful evaluation. You should identify the technology and manufacturing capabilities of each provider. Consider the size of the company and whether it matches your project needs. Evaluate their in-house capabilities and location to ensure efficient communication and logistics.

- Assess the provider’s experience with custom cable assembly and similar electronic products.

- Look for specialization that fits your target market.

- Review their communication style and company values to ensure a good fit.

A strong EMS partner helps you achieve reliable, high-quality assemblies and supports your growth in the electronic manufacturing industry.

Quality and Best Practices

Inspection Techniques

You need strong inspection techniques to maintain high standards in electronic manufacturing. Quality control starts with accurate data management. You collect, store, and analyze production data to monitor quality and improve your processes. Components management helps you track every part, making sure each one meets strict standards. Process management lets you plan and control production steps, so you follow best practices and industry guidelines.

| Quality Control Method | Description |

|---|---|

| Data Management | Collect, store, and analyze production data to monitor quality and improve processes. |

| Components Management | Track components to ensure they meet quality standards, reducing defects. |

| Process Management | Plan and control production processes to adhere to best practices and standards. |

You should use these methods to catch defects early and keep your products consistent. Accurate data also supports traceability and compliance with industry standards.

Reliability Testing

You must test your products for reliability before they reach customers. Reliability testing checks if your devices can handle real-world use and harsh conditions. You use several methods to measure how well your products perform over time.

| Testing Method | Description |

|---|---|

| Load Testing | Check how the product handles normal operating conditions. |

| Stress Testing | Simulate extreme conditions to see how the product performs under pressure. |

| Endurance Testing | See if the product can handle long periods of use without degrading. |

| Recovery Testing | Test how well the product recovers from failures or crashes. |

| Accelerated Life Testing | Speed up the aging process to identify potential weaknesses. |

You should run these tests to ensure your products meet customer expectations for reliability. Consistent testing helps you find weak points and improve your designs. When you focus on reliability, you build trust with your customers and reduce costly returns.

Tip: Always include reliability testing in your process. This step protects your reputation and ensures long-term success.

Industry Standards

You must follow industry standards to guarantee quality and reliability in your products. These standards set clear rules for safety, performance, and environmental impact. Leading organizations like ISO and IPC create guidelines that you need to follow.

| Standard Code | Description |

|---|---|

| ISO 3834-2 | Quality Requirements for Fusion Welding |

| ISO 9001 | Quality Management System |

| ISO 14001 | Environmental Management System |

| ISO 45001 | Occupational Health & Safety Management System |

| ANSI/ESD S20.20 | Electrostatic Discharge Control |

| IPC Standards | Over 300 standards for electronics manufacturing |

- IPC standards ensure reliable and high-quality electronics.

- They clarify expectations across the industry.

- Over 300 active IPC standards cover nearly every stage of electronics product development.

You should stay updated on these standards to keep your manufacturing process current. Following these guidelines helps you deliver products that meet global expectations for quality and reliability.

Beginner Tips Guide

Common Pitfalls

You will face several challenges as you start your journey in electronic manufacturing. Many beginners make similar mistakes, but you can avoid them by learning from others’ experiences. Here are some of the most frequent pitfalls:

- Failing to design for manufacturing from the start

- Incorrect design of wireless circuits

- Waiting too long to estimate manufacturing cost

- Using insufficient width for high-current PCB traces

- Skipping design reviews

- Incorrect use of decoupling capacitors

- Neglecting early-stage feasibility testing

- Poorly defined requirements and user needs

- Underestimating compliance and certification needs

- Skipping iterative prototyping

- Ignoring power and thermal management

- Overlooking trace spacing, trace widths, and via sizing

Tip: Always review your design with a mentor or experienced engineer before moving forward. Early feedback can save you time and resources.

Learning Resources

You can accelerate your learning by using trusted resources recommended by industry experts. These platforms and certifications provide structured knowledge and practical skills:

- Tooling U-SME: Online training and certifications in manufacturing fundamentals

- Certified Manufacturing Associate (CMfgA): Focuses on basic manufacturing concepts for entry-level roles

- Certified Additive Manufacturing – Fundamentals (CAM-F): Covers additive manufacturing basics and safety

- Robotics in Manufacturing Fundamentals (RMF): Certification for robotics in manufacturing

For hands-on practice and community support, explore these online platforms:

| Platform | Description | Benefits |

|---|---|---|

| YouTube Educational Channels | High-quality PCB design tutorials for all skill levels | Structured learning paths and practical examples |

| Coursera and edX Free Courses | University-level PCB design courses with assignments | Peer reviews and certificates upon completion |

| EEVblog Forum | Active discussions with experienced professionals | Real-time feedback and design review opportunities |

| Reddit Communities | Subreddits focused on PCB design and electronics engineering | Informal learning and quick answers to specific questions |

| Open-Source Hardware Study | Analyze existing designs for professional insights | Learn design patterns, component selection, and layout optimization |

Next Steps

You can take several actions to build your skills and confidence in electronic manufacturing. Start by following a step-by-step guide for your first project. Join online forums and communities to ask questions and share your progress. Practice with free design tools and review open-source projects to understand real-world applications. Seek feedback from experienced engineers and never hesitate to iterate on your designs.

Remember, every expert started as a beginner. Use this guide as your foundation and keep exploring new resources. Your curiosity and persistence will drive your success in electronic manufacturing.

You have learned the essential concepts in electronic manufacturing, from PCB basics to quality control. Remember these key steps as you move forward:

- Always put safety first in your workspace.

- Keep your components organized and labeled.

- Never stop learning—use tutorials and manuals to build your skills.

- Breadboards help you prototype without soldering.

- Multimeters let you diagnose and troubleshoot circuits.

Explore hands-on projects and deepen your understanding of voltage, current, and resistance. Stay curious and keep building—your journey in electronics starts now!

2025-09-19

2025-09-19

BEST

BEST

.png)

.png)

.png)

.png)

.png)