When you select between coverlay flex and solder mask for your flex PCB, your application needs will guide your choice. Use coverlay flex for superior durability and protection in harsh environments. Solder mask suits cost-sensitive projects and allows for finer details. The table below highlights key differences to help you decide:

| Aspect | Flexible Solder Masks | Coverlay |

|---|---|---|

| Material | LPI, thin and precise | Polyimide, thicker |

| Durability | Basic protection | Superior protection |

| Flexibility | Very flexible | Less flexible |

| Cost | Cost-effective | Higher, more reliable |

Key Takeaways

- Choose coverlay flex for high durability and protection in harsh environments. It is ideal for applications like medical devices and aerospace electronics.

- Opt for flexible solder mask when cost is a concern and you need fine details. It works well for simpler designs and prototypes.

- Consider the flexibility and thickness of materials. Coverlay flex offers superior flexibility, while solder mask is thinner and lighter.

- Evaluate your project's requirements carefully. Ask about bending frequency, environmental exposure, and the need for fine-pitch components.

- Avoid common mistakes by following IPC standards. Proper material selection and application are crucial for the reliability of your flex PCB.

Coverlay Flex vs Flex PCB Solder Mask

What Is Coverlay Flex

You use coverlay flex as a protective layer in flex PCB designs. This material consists of a solid polyimide sheet combined with an adhesive. You apply it to the flexible circuit to shield copper traces from moisture, chemicals, and mechanical damage. Coverlay flex creates a robust barrier that withstands repeated bending and flexing. You often see flexible coverlay in high-reliability applications, such as medical devices or aerospace electronics, where performance and protection matter most.

What Is Flex PCB Solder Mask

Flex PCB solder mask is a liquid epoxy-based coating that you apply over the copper circuitry of a flex PCB. This flexible solder mask offers basic protection against oxidation and short circuits. You can achieve precise coverage, making it ideal for designs with fine-pitch components or intricate patterns. Flexible solder mask works well for cost-sensitive projects or when you need to maintain a thin, lightweight profile. However, it does not provide the same mechanical strength as coverlay.

Main Differences

When you compare coverlay and flexible solder mask, you notice clear differences in material, application, and performance.

- Coverlay is a solid polyimide film, while flexible solder mask is a liquid coating.

- You get better mechanical protection and insulation from coverlay, making it suitable for high-reliability flex PCB applications.

- Flexible solder mask allows for finer feature resolution but lacks the bonding strength needed for stiffeners or heavy-duty flexing.

- Flexible coverlay creates an impermeable barrier with excellent dielectric properties, while flexible solder mask offers limited insulation and durability.

| Property | Coverlay Flex (FPC Coverlay) | Flex PCB Solder Mask |

|---|---|---|

| Insulation | Strong, excellent dielectric | Limited, not impermeable |

| Durability | More robust and durable | Less durable, like rigid PCBs |

| Flexibility | Superior, ideal for high-reliability | Limited, best for fine-pitch |

You should choose coverlay and flexible solder mask based on your project’s needs. If you require maximum flexibility and long-term performance, flexible coverlay stands out as the best option. For projects where cost and fine detail matter more, flexible solder mask may suit you better.

Pros and Cons

PCB Board Flexibility

When you design a flex pcb, flexibility stands as a top priority. Coverlay flex gives you flexibility throughout the entire board. You can twist and bend the flexible circuit board around corners or fit it into tight spaces without snagging on parts. This makes installation easier and allows you to create unique shapes for your application.

- You can maintain flexibility throughout the lifespan of the board, avoiding rigidity over time.

- Flexible coverlay lets you bend the board into unusual shapes, giving you more design options.

- You do not need to build around the circuit board, which saves space and simplifies assembly.

However, coverlay also brings some limitations:

- You must consider component placement, as mounting components in bend areas can cause damage.

- You may need to redesign layouts or use less densely packed components.

- Careful handling during assembly is necessary to prevent damage.

A flexible circuit board that uses a polyimide-based coverlay instead of a traditional solder mask achieves greater flexibility. The difference between solid sheet coverlay and liquid epoxy solder mask is significant. While coverlay supports full board flexibility, a flex pcb solder mask can limit flexibility, especially in areas that require frequent bending.

Print Circuit Board Durability

Durability plays a crucial role in flex pcb performance. Coverlay provides superior protection against moisture, chemicals, and mechanical stress. You can rely on flexible coverlay for high-reliability applications, such as medical devices or aerospace electronics.

- Coverlay offers excellent insulation and mechanical strength.

- Fpc coverlay resists cracking and delamination, even after repeated flexing.

- Flexible coverlay maintains its protective properties over time, ensuring long-term reliability.

In contrast, flexible solder mask delivers basic protection similar to that of rigid PCBs. It works well for simple flex pcb designs but may not withstand harsh environments or repeated bending.

- Flexible solder mask can wear down or crack in high-flex areas.

- It does not provide the same level of insulation or moisture resistance as coverlay.

- You may see reduced durability in demanding applications.

If you need maximum flexibility and durability, coverlay and flexible solder mask differ greatly. Coverlay stands out for its robust protection, while solder mask suits less demanding environments.

PCB Fabrication Cost

Cost often influences your choice between coverlay and flexible solder mask. Coverlay flex increases material and processing costs due to its thicker polyimide film and adhesive layers. You also face longer lead times with coverlay.

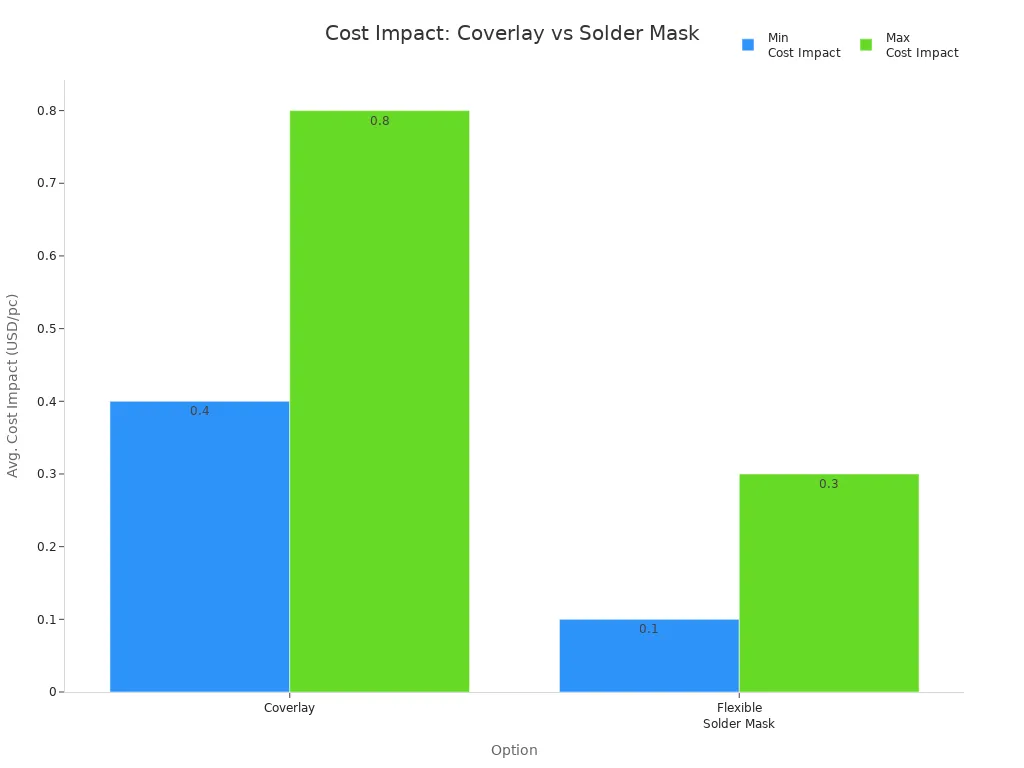

The following table compares the average cost impact for medium-volume production:

| Option | Avg. Cost Impact | Pros | Cons |

|---|---|---|---|

| Coverlay | +$0.40–$0.80/pc | Excellent durability, insulation | More expensive, longer lead time |

| Flexible Solder Mask | +$0.10–$0.30/pc | Cost-effective, good for fine-pitch | Less reliable in flexing zones |

You can reduce costs by choosing flexible solder mask for simple designs or prototypes. However, if your application demands high reliability, the extra investment in coverlay pays off with better performance and longer lifespan.

Application Complexity

The complexity of applying coverlay and flexible solder mask affects both production yield and defect rates. Coverlay requires precise alignment, controlled adhesive application, and careful handling to avoid damaging fragile fibers. You must follow unique design guidelines, which can complicate the process.

- Limited glue quantity can lead to poor adhesion with coverlay.

- Fpc coverlay may suffer from adhesion issues if not applied correctly.

- You need to avoid placing components or stiffeners in bend areas, which restricts design flexibility.

Flexible solder mask offers a simpler application process. You can achieve better adhesion and more flexible design options. However, solder mask cannot accommodate stiffeners or EMI/RF shields, and its bond strength is lower in critical areas.

The table below highlights key challenges:

| Challenge | Coverlay Flex | Flex PCB Solder Mask |

|---|---|---|

| Adhesion Issues | Limited glue quantity can lead to poor adhesion. | Generally better adhesion properties. |

| Design Constraints | Unique design guidelines complicate application. | More flexible design options available. |

| Material Properties | Fragile fibers can be damaged during production. | More robust against physical stress. |

Tip: You can improve production yield and reduce defects by following IPC-2223 standards for solder mask clearances and ensuring complete overlay protection in moisture-sensitive regions.

When you weigh the pros and cons, consider your application's requirements for flexibility and durability, as well as your budget and production capabilities. The right choice between coverlay and flexible solder mask will help you achieve optimal performance for your flex pcb.

Design Factors for Flexible Coverlay

Flex PCB Thickness

When you design a flex pcb, thickness plays a critical role in both flexibility and durability. You must select the right thickness for coverlay flex to achieve optimal performance. Industry guidelines recommend a typical coverlay thickness between 0.025mm and 0.075mm (25µm to 75µm). This range allows you to balance mechanical strength with the ability to bend and twist the flexible circuit. For most applications, a single-layer stack-up might include 25 microns of substrate, 17.5 microns of copper, and 25 microns of coverlay, resulting in a total thickness of 0.0675 mm.

You should also compare the difference between solid sheet coverlay and liquid epoxy solder mask. The table below shows how coverlay flex and flex pcb solder mask differ in thickness:

| Material Type | Thickness (micrometers) |

|---|---|

| Coverlay Flex | 27.5 - 50 |

| Flex PCB Solder Mask | 8 - 12 |

Thicker coverlay provides better protection but may reduce flexibility. Thinner flexible solder mask keeps the board lightweight and allows for finer details.

Overlap and Adhesion

You need to pay close attention to overlap and adhesion when working with flexible coverlay. Proper overlap ensures that the coverlay protects exposed copper areas and maintains electrical integrity. You should size pads and coverlay openings to allow for adhesive squeeze out. This practice helps you achieve strong adhesion and prevents delamination during repeated flexing.

For high-speed applications, you may prefer adhesive-less materials. If you use adhesive-based coverlay, opt for acrylic adhesives with a thickness of 1 mil. Allow for squeeze-out to ensure adhesive leakage while maintaining enough exposed copper for soldering.

You must also consider that certain materials may not adhere well to flex pcb solder mask. The use of coverlay in FPC coverlay and rigid-flex designs is necessary in specific areas due to adhesion issues. Adherence to IPC quality control requirements is essential for reliable flexible solder mask and coverlay and flexible solder mask applications.

Tip: Always check for proper overlap and adhesion to avoid reliability problems in your flex pcb.

IPC Standards

You must follow IPC standards to ensure your flex pcb meets industry requirements for reliability and performance. IPC-2223 provides design guidelines for flex and rigid-flex PCBs, helping you maintain electrical integrity and mechanical durability. IPC-4203 covers materials for coverlay and bonding, while IPC-4204 focuses on flexible metal-clad dielectrics. IPC-6013 sets qualification and performance specifications for flex and rigid-flex PCBs.

The table below summarizes the most relevant IPC standards for flexible coverlay and flexible solder mask:

| IPC Standard | Focus |

|---|---|

| IPC-4203 | Cover and Bonding Materials for flexible PCBs |

| IPC-4204 | Flexible Metal-Clad Dielectrics used in fabrication |

| IPC-2223 | Design guidelines for Flex & Rigid-Flex PCBs |

| IPC-6013 | Qualification and Performance Specifications for Flex PCBs |

You should always reference these standards during design and manufacturing. Following IPC guidelines helps you avoid common mistakes and ensures your flexible circuit delivers consistent performance.

Note: Design factors for flexible solder mask and coverlay must align with IPC standards to guarantee long-term reliability.

Choosing Coverlay or Solder Mask for Flex PCB

Decision Criteria

You need to evaluate several factors before you select coverlay or flexible solder mask for your flex PCB. Application requirements such as bend radius, environmental exposure, and electrical insulation play a major role in your decision. Coverlay flex, made from polyimide, offers strong protection and insulation. Flexible solder mask provides electrical insulation and prevents solder bridging. You must consider the minimum bend radius to maintain the mechanical integrity of your flexible circuit. Environmental factors, such as thermal stability and moisture absorption, also influence your choice.

When you design a flexible circuit board, ask yourself these questions:

- Will your flex PCB experience frequent bending or twisting?

- Does your application require high resistance to moisture, chemicals, or temperature extremes?

- Do you need fine-pitch components or thin board profiles?

- Is long-term reliability more important than initial cost?

If you answer yes to the first two questions, coverlay and flexible coverlay are likely the best options. If you need fine detail and cost savings, flexible solder mask may suit your flex PCB design.

Tip: Always match your material selection to your application's mechanical and environmental demands. Proper material choice ensures durability and reliable performance.

Typical Applications

You see coverlay flex and flexible solder mask used in many industries. Coverlay provides robust protection for flex PCBs in harsh environments. Flexible solder mask works well in cost-sensitive designs and applications that require thin, lightweight circuits.

Here are common applications for coverlay and flexible coverlay:

- Consumer electronics: Smartphones, wearables, foldable displays

- Automotive: Flexible dashboards, sensors, lighting systems

- Medical devices: Implantable devices, wearable monitors, diagnostic equipment

- Aerospace and defense: Satellites, avionics, drones

- Industrial and telecommunications: Robotics, 5G infrastructure, solar panels

Flexible solder mask is popular in designs with fine-pitch components and simple flex requirements. You often see it in consumer electronics and low-cost prototypes.

| Application Area | Coverlay/Flexible Coverlay | Flexible Solder Mask |

|---|---|---|

| High-reliability flex | ✔ | |

| Fine-pitch components | ✔ | |

| Cost-sensitive projects | ✔ | |

| Harsh environments | ✔ | |

| Thin/lightweight boards | ✔ |

You should choose coverlay for applications that demand durability and insulation. Select flexible solder mask when you need precise coverage and lower costs.

Common Mistakes

You must avoid frequent mistakes when choosing between coverlay and flexible solder mask. Many engineers overlook the reduced adhesion capacity of flexible solder mask when electromagnetic interference shielding is needed. This can lead to poor performance. Some designers do not apply materials carefully in configurations where neither coverlay nor solder mask meets all design criteria. This can cause structural issues in your flex PCB.

Other common mistakes include:

- Failing to consider the positioning of coverlay and solder stencil, which creates gaps and compromises reliability

- Ignoring the minimum bend radius, resulting in mechanical stress and signal integrity problems

- Using coverlay in rigid areas or flexible solder mask in high-flex regions, which reduces durability

- Not following design factors for flexible solder mask and coverlay, leading to delamination or cracking

Note: Proper material selection and application are essential for the durability and functionality of your flex PCB. Always protect flex regions with fpc coverlay and use flexible solder mask on rigid areas.

You can prevent these errors by reviewing IPC standards and consulting with PCB experts during the design phase. Careful planning and attention to detail will help you achieve reliable, high-performance flexible circuits.

You should select flexible coverlay for flex designs that demand high durability, frequent bending, and robust protection. Flexible solder mask works best for cost-sensitive projects and fine-pitch component areas. The table below summarizes the main features:

| Feature | Polyimide Coverlay | Flexible LPI Solder Mask |

|---|---|---|

| Durability | Superior | Moderate |

| Flexibility | High | Moderate |

| Cost | Higher | Lower |

| Industry Standard | Yes | No |

- Flexible coverlay and fpc coverlay provide industry-standard reliability for dynamic flex applications.

- Flexible solder mask suits static flex or low layer count designs.

- You can combine both materials for optimal performance.

Consult with PCB experts to match flexible coverlay or flexible solder mask to your specific flex requirements. Explore new material trends and manufacturing techniques for advanced flexible electronics.

2025-09-01

2025-09-01

BEST

BEST

.png)

.png)

.png)

.png)

.png)