Scientific research tools use electronics that are very delicate. These electronics need strong protection to work well. Polyimide pcb gives this protection because of its special features. It can stand very hot or cold temperatures. It does not get damaged by strong chemicals. It also keeps out water and moisture. The material is great at stopping electricity from leaking. Polyimide pcb can bend, so engineers can make circuits in many shapes and sizes. All these things help lab devices work well and last a long time, even when things get tough.

Key Takeaways

- Polyimide PCBs keep lab electronics safe from very hot or cold temperatures. They work well from -200°C to 300°C. This helps lab tools work well in tough places.

- These boards do not get hurt by strong chemicals or water. This stops damage and helps lab equipment last longer.

- Polyimide PCBs are strong and can bend. This lets engineers make small and tough circuits for new lab devices.

- Using polyimide PCBs can save money on repairs over time. They do not break as easily as normal circuit boards.

- Picking polyimide PCBs makes lab tools work better. This helps scientists get good results in their research.

Polyimide PCB Protection

Thermal and Chemical Resistance

Polyimide pcb works well in labs because it can handle very hot and very cold temperatures. It keeps working from -200°C up to 300°C. Most other circuit boards cannot work in such extreme heat or cold. Scientists use tools that get hot or cold very fast. Polyimide pcb keeps circuits safe when the temperature changes.

Chemicals in labs can hurt normal circuit boards. Polyimide pcb does not get damaged by strong acids, bases, or solvents. The board stays strong even when it touches harsh chemicals. It also protects against water, which is important in labs with lots of moisture.

- Polyimide pcb does not soak up much water.

- This helps it resist moisture better than many other circuit board materials.

- Moisture resistance stops short circuits and helps lab devices last longer.

Polyimide pcb is a strong electrical insulator. It keeps electricity from leaking out of the circuit. This protects sensitive lab electronics and helps them work as they should.

Tip: Using polyimide pcb in lab equipment helps keep valuable electronics safe from heat, chemicals, and moisture.

Mechanical Strength and Flexibility

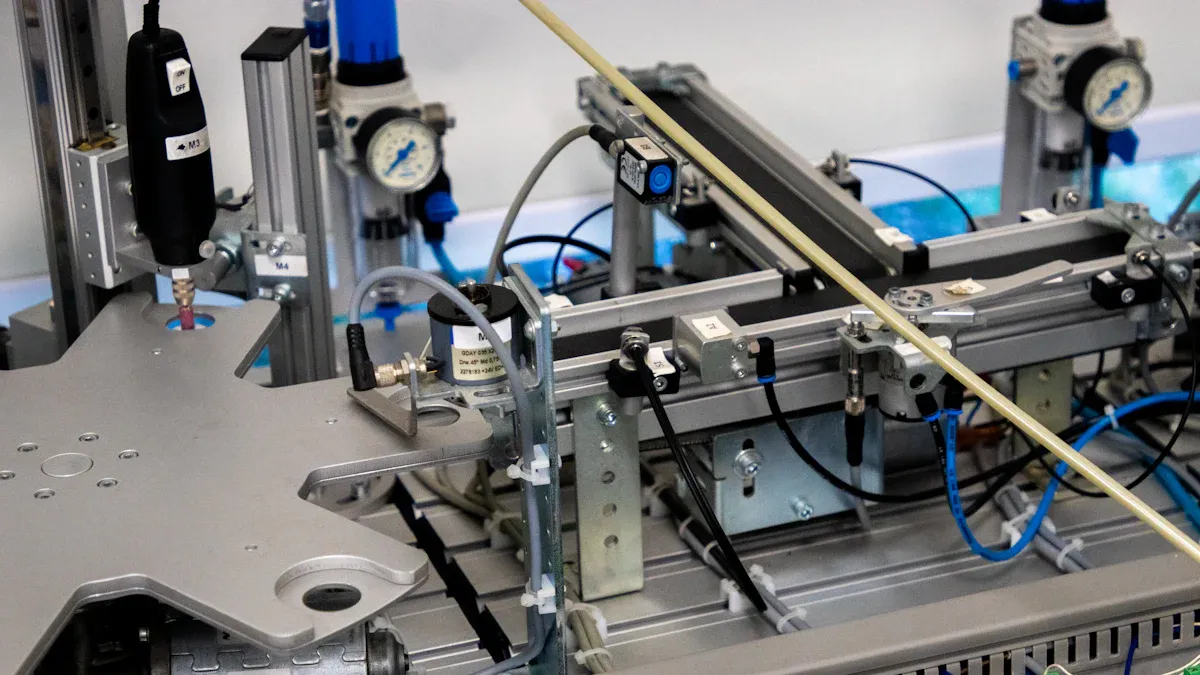

Polyimide pcb does more than protect against heat and chemicals. It also gives strong support. The material can bend and flex without breaking. Engineers can make circuits that fit into small or strange spaces. This is good for modern lab devices that need to be small and light.

Polyimide pcb does not crack when bent or twisted. This makes it great for equipment that moves or shakes during use. The board is strong, so it can handle bumps, drops, and daily use in busy labs.

Polyimide pcb helps labs build devices that last a long time. Its special mix of strength and flexibility helps new ideas in science and technology.

Applications in Research Equipment

Analytical Instruments

Lots of labs use tools like spectrometers and chromatographs. These tools help study chemicals and materials. They need circuit boards that work well and do not break. Polyimide pcb helps these tools work in hard lab places. It keeps out heat, water, and chemicals. This keeps the electronics safe inside. Scientists who study medicine and biology trust these boards. The boards help keep their data correct.

Imaging Devices

Imaging machines like MRI and electron microscopes need exact electronics. Polyimide pcb lets engineers use many layers in one board. This is important for handling signals that move fast. The boards keep analog and digital signals apart. This lowers noise and makes pictures better. They also help control power for strong parts. These parts include gradient coils and RF amplifiers. Engineers use these boards to make machines that give clear and steady images.

- Boards with many layers handle hard signals.

- Boards keep analog and digital paths apart to lower noise.

- Power control helps strong machine parts work well.

Environmental Sensors

Sensors check air, water, and soil in labs and outside. These sensors work in tough places and need good protection. Polyimide pcb gives strong insulation and support. This helps sensors last longer and work better. The material keeps working in hot, cold, or wet places.

| Aspect | Description |

|---|---|

| Material | Polyimide protects sensors with strong heat, strength, and electrical features. |

| Role in Durability | Gives insulation and protection, so sensors last longer. |

| Impact on Accuracy | Covering sensors may lower sensitivity, so engineers must balance safety and accuracy. |

Lab-on-PCB Platforms

Lab-on-PCB platforms put many lab jobs on one board. These systems help with quick tests and small experiments. Polyimide pcb lets engineers make boards that bend and fit in small spaces. Researchers use these boards in medicine, testing, and checking the environment. The boards are strong and resist chemicals. This makes them great for new lab tools.

Note: Polyimide pcb helps research tools work well for a long time. This helps labs get good results, even when things are hard.

Why Choose Polyimide PCB

Performance in Labs

Lab tools have to work in hard places every day. Engineers want boards that can handle heat, water, and chemicals. Polyimide pcb keeps working when other boards stop. It protects important electronics and helps them last longer.

You can check how good a PCB is by looking at its CTI value, how long it lasts, and how well it stops tracking problems. The table below shows how polyimide pcb does compared to normal FR-4 boards in labs:

| PCB Type | CTI Value (V) | Lifespan (Years) | Tracking Failures Reduction |

|---|---|---|---|

| Class 3 (Low-Tg FR4) | 250–399 | 3 | N/A |

| Class 2 (Mid-Tg FR4) | 400–599 | 7 | 82% |

| Class 1 (High-Tg FR4) | ≥600 | N/A | N/A |

A bigger CTI value means the board is better at stopping electrical tracking. Polyimide pcb often has the same or better CTI than the best class. This gives labs more trust in their results. Devices with these boards break less and last longer.

Tip: Picking the right PCB helps labs save money and avoid repairs.

Reliability vs. Other Materials

Polyimide pcb costs more than regular boards. The special material and how it is made make it pricier. But the good things about it are worth the cost. Flexible polyimide boards let engineers make cool new designs. They can use fewer connectors and cables, which saves space and stops loose parts.

These boards can bend and move without breaking. This is great for tools that have moving parts or need to fit in small spots. Even though they cost more, labs get better tools that last longer.

- Less fixing means labs save money over time.

- Flexible boards help labs put more things in small devices.

- Strong boards keep working in tough lab places.

Labs that pick polyimide pcb are choosing safety, good results, and value that lasts.

Real-World Use Cases

Case Studies

Many labs use polyimide PCBs for important tools. MRI machines are a good example. Engineers put rigid-flex polyimide PCBs inside MRI machines. These boards help control electronics and RF coils. The boards keep the machines working well, even in hard places.

MRI machines have strong magnets and shake a lot. Old circuit boards break in these tough spots. Rigid-flex polyimide PCBs fix this problem. They cut down connection points by 60%. Fewer connections mean less chance of breaking. This makes MRI machines safer and more reliable.

The table below shows how polyimide PCBs help MRI machines:

| Application | Reliability Factor | Environmental Stress |

|---|---|---|

| MRI Machines | Rigid-flex PCBs cut connection points by up to 60%, lowering failure risks | Boards handle strong magnetic fields (1.5–3 Tesla) and vibrations better than others |

Note: Hospitals and labs pick polyimide PCBs for MRI machines. They want tools that last and work every time.

Research Lab Examples

Polyimide PCBs help in many other labs too. Scientists use them in electron microscopes, spectrometers, and sensors. These devices work in places with heat, water, or chemicals. Polyimide PCBs keep the electronics safe and working.

- In a Swiss biotech lab, engineers made a DNA analyzer with a flexible polyimide PCB. The board let them fit the device in a small case. The analyzer worked in hot and cold rooms.

- Environmental scientists use sensors with polyimide PCBs to test water. The boards resist water and chemicals, so the sensors last longer.

Polyimide PCBs help labs save money by needing fewer repairs. They also help scientists trust their results because the tools stay reliable.

Tip: Picking polyimide PCBs helps labs in Switzerland and everywhere build better, longer-lasting tools.

Polyimide PCBs help keep lab electronics safe. They make devices last a long time. Scientists and engineers use these boards in many research tools. Polyimide PCBs work well with heat, chemicals, and moisture. They do better than most other materials.

Labs in Switzerland and other places use polyimide PCBs for safer equipment. People who design new lab devices should pick these boards for good results.

2025-09-02

2025-09-02

BEST

BEST

.png)

.png)

.png)

.png)

.png)