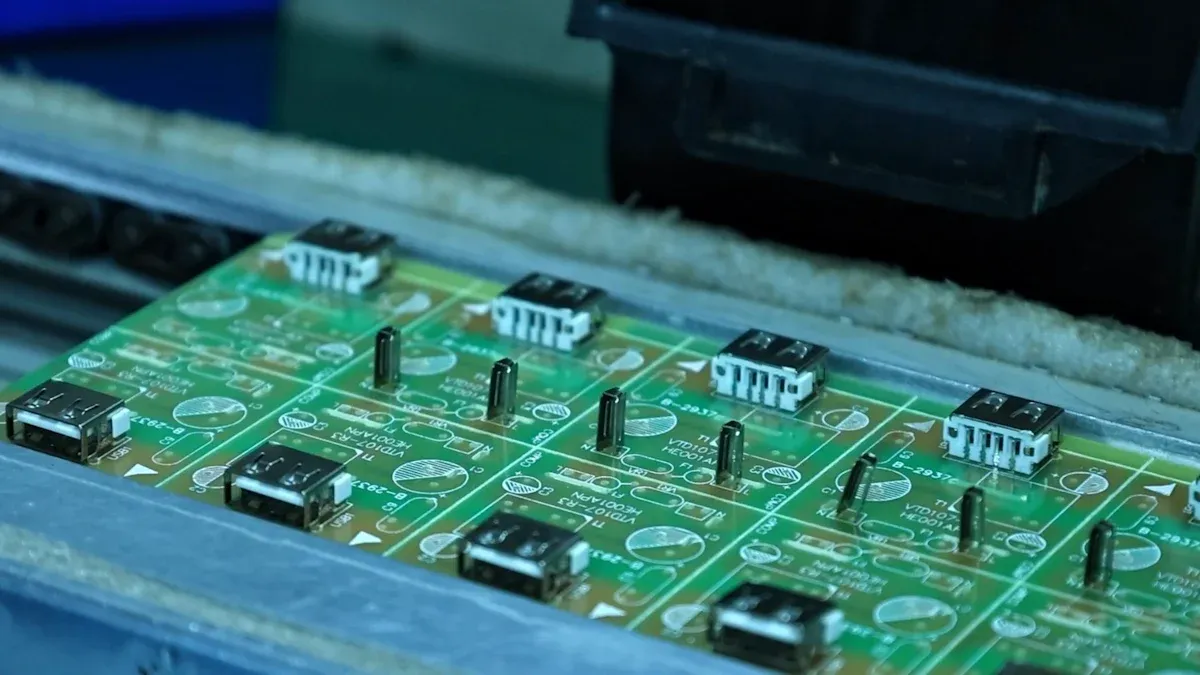

I see how rigid flex circuits help new ideas in electronics. They mix rigid and flexible layers. This lets me make small designs for communication devices. When I use these circuits, I see many good things:

- There are fewer connectors and solder joints. This means the industry gets more reliable products.

- The boards are thinner and can bend in 3D. This helps me put circuits in small spaces. Fitting parts in tight spots is hard in electronics.

- High-density connections help with advanced design needs in the industry.

- Fast prototyping services from top companies let me test ideas quickly. This helps me keep up with new changes.

All these features help me make changes fast. They also help the industry reach high goals for design and reliability.

Key Takeaways

- Rigid flex circuits use both stiff and bendable layers. This helps make devices smaller, tougher, and more dependable.

- These circuits let engineers change designs fast. They can try almost 100 versions to test and fix products quickly.

- Flexible circuit boards can fit in small spaces. They can bend and twist, so they work well in wearables, foldable phones, and smart sensors.

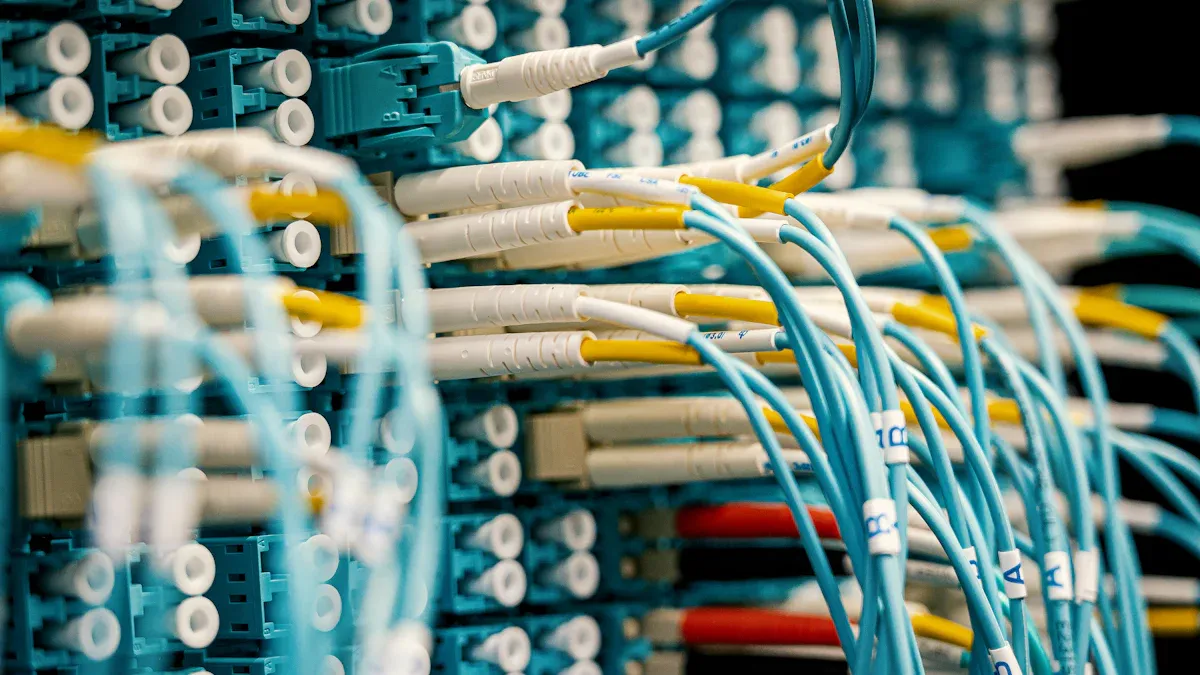

- Using special materials and smart design makes the circuits last longer. It also helps signals stay strong and keeps things cool in communication electronics.

- Working together, building quick samples, and making clear plans help make products faster. This also helps make sure the products are new and high quality.

Which electronic devices have been updated due to Rigid Flex PCBs innovation?

I notice that rigid flex circuits use both rigid PCB technology and flexible circuit boards. This mix lets me make electronics that fit in small and tricky spaces. I use rigid PCB design when I need strong support. I use flexible PCB technology when I need to bend or fold the board. This way, I can build advanced communication devices that are small and work well.

Many electronics have changed because of this. Here are some examples:

- VR headsets now use rigid flex circuits to fit better on your head. Old rigid PCB technology made these headsets big and hard to wear. Flexible circuit boards let me shape the circuits to match the headset. This makes them lighter and lets me add things like eye-tracking sensors and straps you can adjust. The headset feels more comfortable and natural to wear.

- Foldable phones and smartwatches need to bend and move a lot. Flexible circuit boards help them last through many folds and twists. I use flexible PCB technology so they do not break easily.

- Wireless earbuds and wearable medical devices also use this technology. I can put more features in smaller spaces. This makes these devices more helpful and comfortable for people.

Surveillance Cameras

When I work on surveillance cameras, I see how rigid flex circuits help a lot. These cameras need to be small, light, and tough. I use special imaging tools like Laser Direct Imaging to make tiny lines. This helps me make the circuits more exact and with fewer mistakes. Special machines help me keep the board from bending the wrong way. This keeps the product high quality. Good impedance control helps with fast signals, which is important for image sensors. Rigid flex circuits also make the camera stronger and the signals clearer. This is very important for camera modules that need to work well. I can add complex sensors and many layers, so these cameras work better in hard places.

Remote Control Aircraft

Remote control aircraft, like drones, are better now because of rigid flex circuits. I use flexible circuit boards that can take heat and shaking. For example, big planes use these circuits in navigation systems to handle strong shaking. Defense tools, like night-vision goggles, use light designs made with flexible PCB technology. Rigid flex circuits give both flexibility and strength. This makes them last longer and handle stress better. This technology makes things lighter, helps with shaking, and blocks EMI. These things are needed for remote control aircraft and other tough electronics.

Tip: When I pick between flexible circuit boards and rigid PCB technology, I think about what the device needs. Flexible PCBs are best for small, moving, or odd-shaped electronics. Rigid PCB design works better for things that do not move and need lots of power.

| Feature | Flexible Circuit Boards (Flex PCBs) | Rigid PCBs |

|---|---|---|

| Flexibility | Can bend many times (over 10,000) with a small bend radius | Stiff and will break if you try to bend them |

| Weight | 50–70% lighter than rigid boards of the same size | Heavier because of thick material and connectors |

| Space Efficiency | Fits in tight, odd spaces (like smartwatch cases); no wiring harness needed | Needs flat space to mount; needs connectors for big builds |

| Thermal Management | Handles heat well (polyimide can take -200°C to 260°C) but is thin | Handles heat better (FR-4 can take 130°C+; high-Tg up to 170°C) |

| Cost | Costs 2–3 times more at first because of special materials and making | Cheaper per board, especially if you make a lot (over 10,000) |

| Best Applications | Great for small, moving, or odd-shaped devices; good for places with lots of shaking | Best for things that do not move, need lots of power, or must be cheap |

I always care about quality and getting things done on time. These things help me make great electronics and help people live better lives.

Nearly 100 Iterations Because Of Rigid Flex Circuits

I work with communication electronics. The industry changes very fast. I need to keep up with new technology and what people want. Fast innovation is not just a wish. It is something I must do. I use flexible circuit boards and rigid flex circuits to help me make almost 100 designs for each product. This way, I can test ideas, see what works, and fix problems quickly.

When I make new electronics, I follow steps that experts suggest:

- I check my designs early with simulation and by making models. This helps me find mistakes before I build the real thing.

- I talk a lot with people from engineering, manufacturing, and quality teams. We work together to fix problems with making the product.

- I make and test many models. This helps me find problems that computer tests might miss.

- I change each design to make it creative but also easy to build. This helps my products be new and not cost too much.

Game Controller-Nintendo

Nintendo game controllers show how flexible circuit boards help make new things. I remember working on designs that needed many parts in a small space. Making things smaller was very important. I used flexible circuit boards to connect buttons, sensors, and motors. These boards bend and twist inside the controller. This makes the controller small and strong. The technology also helps the controller last longer. The controllers do not break easily when dropped or played with a lot. The flexible circuit boards stop vibration and stress from hurting the parts. The signals stay clear, so every button press works well. I see how this technology lets me try many designs fast. This helps make better controllers for gamers.

Laptop Series-Apple

Apple laptops are known for being fast and new. I use rigid flex circuits and flexible circuit boards to make them thin and strong. The design must fit fast processors, batteries, and connectors in a thin case. I pick special materials like LCP to keep signals clear, even when the parts are small. Flexible circuit boards let me put wires around tight corners and through hinges. This makes the laptop last longer and work well in hard places. I can test and change each version, making almost 100 designs before selling it. This makes sure the laptop works great and lasts a long time.

- Making things smaller means I use tiny connectors and packed layouts.

- Strong parts come from good locks and materials that stop shaking.

- Clear signals stay because I control impedance and use shields.

I see how flexible circuit boards and rigid pcb design help me make new, good, and strong products. The industry needs these technologies to make modern electronics work.

Key Features for Iteration

Design Flexibility

Flexible circuit boards let me make many shapes. I can bend them around corners and fit them in small places. This helps me build smaller and lighter electronics. I use special materials like polyimide and rolled annealed copper. These materials let the boards bend and twist without breaking. I put parts where the board does not bend much. This keeps the parts safe and makes the board last longer.

- Flexible circuit boards wrap around curves and save space. They fit into tricky device shapes.

- I use curved lines to spread out stress when the board bends. This makes the board work better.

- I keep the layers low so the board stays flexible. I only add stiffeners where needed, like at connectors.

- These boards are good for things that move a lot, like foldable phones and wearables.

- I always follow bend rules to stop damage and keep the board strong.

Flexible circuit boards give me more choices than rigid boards. I can make new products that were not possible before. This helps me try new ideas and push what electronics can do. I see better parts working together and more reliable devices each time.

Rapid Prototyping

Rapid prototyping helps me work faster. With rigid flex circuits, I can test ideas almost right away. I do not have to wait long for a new board. Sometimes, I get a prototype in just one day. This fast process helps me find and fix problems quickly. I can change my designs without waiting a long time.

- I test each version right away and spot problems early.

- I can try different layouts and materials for better results.

- Each prototype lets me check if everything works before making a lot.

This way saves me lots of time. I read that rapid prototyping with rigid flex circuits can make R&D faster by about 40%. Fewer things break, and more boards work right. I use less material, so I save money. These good things help me make new electronics faster and better.

Tip: Fast prototyping lets me try more ideas. I can get good results and new designs with less risk.

Durability and Testing

Making strong electronics is very important. Flexible circuit boards help me build things that last longer and work better. I use special materials that can take bending, heat, and shaking. I add stiffeners at connectors to protect the copper and parts. This keeps the board strong where it needs to be.

- I design smooth areas between stiff and bendy parts to lower stress.

- I use surface mount contacts and make connectors the best shape. This keeps signals clear and stops problems.

- I test boards that bend a lot to make sure they last a long time.

Having fewer connectors makes the design simpler and keeps signals strong. Fewer connectors mean fewer places for signals to get lost. This gives better performance and more reliable devices. I always care about quality and finishing on time. This helps me make electronics people can trust.

| Feature | Benefit for Iteration |

|---|---|

| Advanced materials | Better endurance and flexibility |

| Fewer connectors | Improved signal integrity |

| Stiffeners at key points | Enhanced mechanical durability |

| Rapid prototyping | Faster design changes and testing |

| Optimized geometry | Reliable performance and integration |

I use these ways in every project. They help me make new things, strong performance, and good quality. My goal is to make electronics that help people and set new standards for reliability.

Real-World Innovation

Smart City Sensors

Smart city sensors are a cool use for rigid flex circuits. These sensors help cities learn about traffic, air, and energy. I use flexible circuit boards to fit parts in small, tough cases. This keeps the sensors safe from rain, dust, and heat. I can put these sensors on streetlights, bridges, or buses. Each sensor must work well outside and send data without mistakes. I make many versions before I find the best one. Rapid prototyping lets me try different shapes and materials. I check how the sensors use power and send signals. I also see if they last a long time. This helps me make better products and finish on time. I have seen how rigid flex circuits make these sensors more accurate and strong. Now, these sensors help cities work better and keep people safe.

Wearable Communication Devices

Wearable communication devices are another good use for rigid flex circuits. I design smart watches, fitness trackers, and health monitors. People wear these every day. These devices must be light, strong, and comfy. Flexible circuit boards let me shape the parts to fit the wrist or body. I can add sensors for heart rate, steps, or the air. I test many designs to make sure they work when people move or sweat. Each new version helps me make the battery last longer and work better. I use rapid prototyping to try new ideas and fix problems fast. These devices need to be high quality and ready quickly. I think rigid flex circuits have changed how I build these smart devices. Now, wearables work better and have more features in small sizes.

Note: I always care about quality and finishing on time. These two things help my new ideas reach people and make life better.

Best Practices

Design Strategies

I always think about how my design will be used in the end. I want every design to be strong and work well. Here are some ways I make my work faster and better:

- I plan for heat early. I look for hot spots and use thermal vias or copper pours to cool them down.

- I keep parts away from places that bend or get pushed. This keeps important parts safe when testing or using the device.

- I do not put noisy circuits close to sensitive parts. This helps stop problems when the device is used.

- I write down every step. I make clear drawings, guides, and a list of parts. This helps the factory team work faster and make fewer mistakes.

- I think about how things are made from the start. I use Design for Manufacturing and Assembly (DFMA) to make sure my design can be built in real life.

- I pick materials that work for both rigid and flexible parts. This helps the device stay strong and last longer.

- I use special tools to put together rigid flex circuits. This helps me get more good boards and better quality.

Tip: I always check my design with computer tools and 3D printing. This helps me see if things fit and work before making a lot. It saves time and cuts down on waste, which is good for the planet.

Team Collaboration

I think working together with the factory team makes better products and gets things done faster. Here is how I make teamwork help me:

- I use rapid prototyping services early. These experts help me test and fix designs quickly.

- I use new ways to make things, like 3D printing and CNC machining. This helps me see real results fast and put things together quicker.

- I pick factory partners who can work fast and do many jobs at once. This helps me change designs for different uses without waiting.

- I talk openly and share updates with all teams. This stops mistakes and helps everyone do a better job.

- I care about the planet, so I pick partners who use green ways and save energy.

| Collaboration Method | Benefit for Iteration and Integration |

|---|---|

| Rapid prototyping services | Faster testing and feedback |

| Integrated manufacturing | Smooth transition from design to production |

| Open communication | Fewer errors and better applications |

| Sustainable practices | Long-term success and eco-friendly solutions |

I see that every good project needs design and factory teams to work together. By following these steps, I make high-quality products that fit what people need in new communication electronics.

I think rigid flex circuits are very important for new communication electronics. They help me try out new ideas quickly and make almost 100 designs. I trust them because I use good materials, careful tests, and smart design choices.

- I handle heat and stress by using special ways to put the layers together. This makes the circuits last longer.

- I choose materials like Shengyi S1140F because they bend well and are strong. This helps the circuits work better for a long time.

- I keep up with new trends that show how important reliability is for 5G, wearables, and new devices.

- I check reliability by testing with heat and by using solder shock tests.

- I make sure my designs have the right bend shapes and extra support to stop damage.

- I focus on reliability from the start of the design to the end of making the product.

- I know that being reliable helps make new and better products.

- I think reliability will be very important for the future of communication electronics.

FAQ

What makes rigid flex circuits better for rapid prototyping?

I pick rigid flex circuits because I can try new ideas fast. I change my designs quickly and see what happens right away. This helps me spot problems early and fix them before selling my products.

How do rigid flex PCBs improve product quality?

I trust rigid flex PCBs to make my devices tough and dependable. With fewer connectors, there are not as many weak spots. These circuits handle heat and stress well. This means my products work better and last longer.

Can rigid flex circuits help with miniaturization?

Yes, I use rigid flex circuits to add more features in small spaces. The flexible parts bend around corners and fit in tight spots. This lets me make small devices like wearables and smart sensors.

Why is on-time delivery important for communication electronics?

On-time delivery keeps my projects moving forward. I can sell products faster and make customers happy. Good PCB suppliers help me avoid delays and keep my work high quality.

What should I look for in a rigid flex PCB supplier?

I always look for strong quality checks, quick prototyping, and clear talks. A good supplier ships on time and helps me change my designs. This teamwork helps me make better products for everyone.

2025-07-31

2025-07-31

BEST

BEST

.png)

.png)

.png)

.png)

.png)