You face a critical choice when selecting a PCB material for your project. Choose fr4 when you need a cost-effective, rigid board for basic digital circuits or moderate temperatures up to 100°C. Opt for rigid polyimide pcb if your design must handle extreme heat, high-frequency signals, or demanding reliability tests. Matching the right material to your application ensures performance and durability.

| Requirement Type | FR4 PCB | Rigid Polyimide PCB |

|---|---|---|

| Cost Sensitivity | Lower cost | Higher cost |

| Temperature Tolerance | Up to 100°C | Over 250°C |

| Flexibility | Rigid | Flexible or rigid-flex |

| Reliability | Standard | Mission-critical |

Key Takeaways

- Choose FR4 for cost-effective solutions in standard electronics. It works well for basic digital circuits and moderate temperatures.

- Opt for rigid polyimide PCBs when your project requires high-temperature resistance and flexibility. They excel in extreme environments and mission-critical applications.

- Consider mechanical strength and chemical stability when selecting a PCB. FR4 offers high strength, while rigid polyimide provides excellent chemical resistance.

- Evaluate your project’s specific needs, including budget, reliability, and environmental conditions, to determine the best PCB material.

- Use the quick reference table in the blog to compare FR4 and rigid polyimide features. This will help you make a more informed decision.

Material Construction Differences

FR4 Structure

You encounter fr4 in most standard printed circuit boards. This material uses a combination of woven fiberglass and epoxy resin. Manufacturers laminate these layers to create a rigid, flame-resistant board that meets UL94V-0 standards. The glass fibers provide mechanical strength, while the epoxy resin binds the structure and adds electrical insulation.

Tip: FR4’s glass-reinforced epoxy laminate offers moderate rigidity and durability, making it suitable for general electronics.

| Material Type | Base Material | Key Properties | Applications |

|---|---|---|---|

| FR4 | Epoxy resin + fiberglass | Cost-effective, standard applications | General electronics |

You benefit from fr4’s structural strength and routing support. The rigid backbone ensures stable performance in environments with moderate mechanical stress. However, fr4 lacks flexibility, which limits its use in designs that require bending or folding.

Rigid Polyimide PCB Structure

Rigid polyimide PCBs use polyimide as the base material. Polyimide stands out for its superior thermal stability and flexibility. Manufacturers construct these boards by layering polyimide films, which can vary in thickness depending on your project’s needs. This material resists chemicals and moisture, making it ideal for harsh environments.

| Material Type | Composition | Durability Characteristics |

|---|---|---|

| Rigid Polyimide | Polyimide materials | High flexibility and excellent thermal resistance |

You gain several advantages with rigid polyimide PCBs. The material construction supports extreme temperature ranges from -55°C to over 200°C. Polyimide’s dielectric constant of around 3.5 ensures good signal integrity for high-frequency applications. The flexibility of polyimide films allows you to design boards that withstand repeated mechanical stress without cracking.

How Construction Impacts Application Suitability

FR4 PCBs:

- Provide reliable mechanical strength for everyday electronics.

- Offer cost-effective solutions for projects with standard temperature and durability requirements.

- Lack flexibility, which restricts their use in dynamic or high-vibration environments.

Rigid Polyimide PCBs:

- Deliver exceptional thermal and chemical resistance.

- Support flexible or rigid-flex designs for aerospace, automotive, and medical applications.

- Maintain integrity in mission-critical systems exposed to harsh conditions.

Note: Material construction differences between fr4 and rigid polyimide PCBs directly influence your choice. You should match the board’s mechanical and thermal properties to your project’s environment and reliability needs.

Material Property Differences

When you compare fr4 and rigid polyimide PCBs, you notice several important material property differences. These differences determine how each board performs in demanding environments and which applications suit them best. Let’s break down the key properties that set these materials apart.

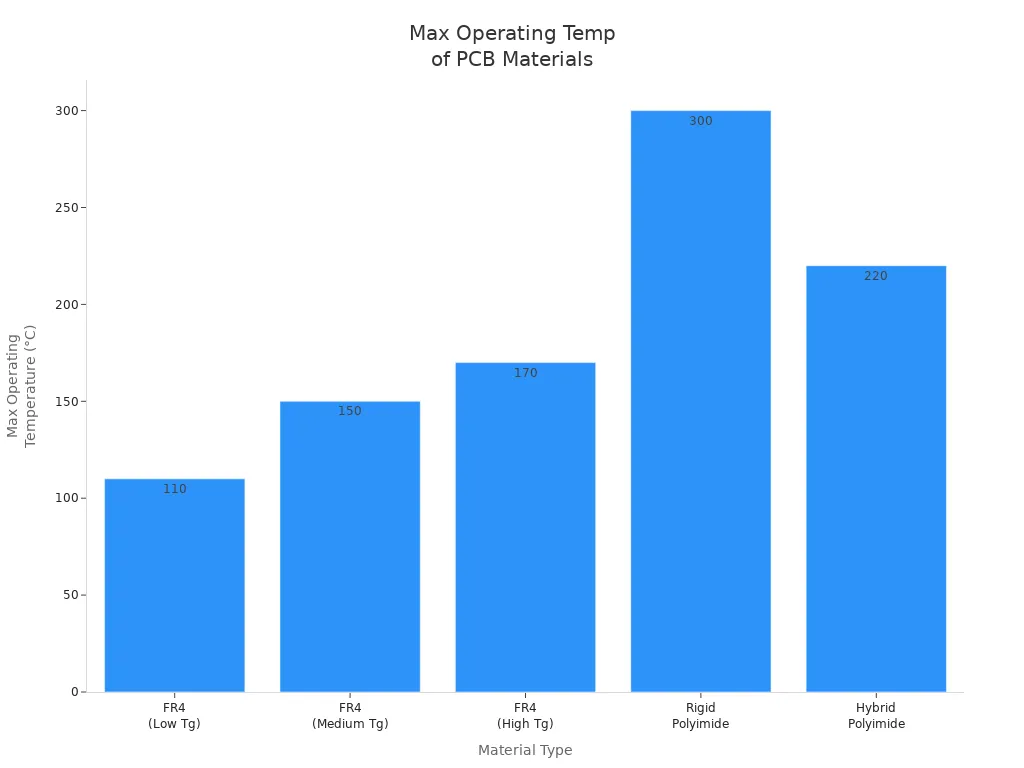

Thermal Resistance

Thermal resistance is a critical factor in PCB selection. You want a board that can withstand the heat generated during operation without losing performance or reliability. Fr4 typically operates safely up to 110°C for standard grades, with high Tg versions reaching above 170°C. However, the epoxy resin in fr4 limits its maximum operating temperature to about 150°C. In contrast, rigid polyimide PCBs excel in high-temperature environments, handling continuous operation up to 300°C. Polyimide circuits can even function in extreme cold, down to -220°C.

| Material Type | Maximum Operating Temperature | Notes |

|---|---|---|

| FR4 (Low Tg) | 110°C | Tg of 130°C |

| FR4 (Medium Tg) | Above 150°C | |

| FR4 (High Tg) | Above 170°C | |

| Rigid Polyimide | 300°C | |

| Hybrid Polyimide | Approx. 220°C | Higher temp rating due to resin |

If your project involves high-power components or must survive harsh thermal cycles, rigid polyimide offers unmatched thermal resistance. Fr4 works well for consumer electronics and industrial controls where temperatures remain moderate.

Mechanical Strength

Mechanical strength defines how well your PCB can handle physical stress, vibration, and load. Fr4 stands out for its robust mechanical strength, making it ideal for rigid, load-bearing applications. You benefit from tensile strength values around 70 MPa, with some sources reporting up to 415 MPa for fr4. This strength ensures your board resists cracking and deformation under pressure.

Rigid polyimide PCBs also provide impressive mechanical strength, with tensile strength values near 231 MPa at room temperature and 139 MPa at 200°C. However, when you use polyimide in flexible designs, mechanical strength decreases. Flexible polyimide boards can tear more easily and have lower impact resistance compared to rigid fr4 boards.

- Fr4 PCBs deliver high mechanical strength and excellent load-bearing capacity.

- Rigid polyimide PCBs maintain good mechanical strength, especially at elevated temperatures.

- Flexible polyimide PCBs trade some mechanical strength for flexibility and lightweight construction.

Choose fr4 for applications that demand rigidity and structural support. Select rigid polyimide when you need a balance between strength and thermal endurance, especially in aerospace or automotive systems.

Chemical Stability

Chemical stability protects your PCB from corrosion and degradation in harsh environments. Fr4 offers moderate resistance to chemicals, making it suitable for most industrial and commercial uses. You can rely on its insulation properties to maintain electrical performance in standard conditions.

Rigid polyimide PCBs outperform fr4 in chemical stability. Polyimide resists corrosive agents and solvents, showing no adverse effects even in aggressive environments. This superior chemical resistance makes polyimide the preferred choice for aerospace, medical, and military electronics, where exposure to harsh chemicals is common.

- Fr4 provides reliable insulation and moderate chemical resistance for general electronics.

- Rigid polyimide ensures long-term durability and insulation in chemically demanding settings.

For mission-critical projects exposed to solvents or corrosive materials, rigid polyimide PCBs deliver the chemical stability you need.

Flexibility

Flexibility is a defining feature when you design for compact or dynamic devices. Fr4 is inherently rigid, which limits its use in applications that require bending or movement. Its mechanical strength supports fixed installations but restricts design freedom.

Rigid polyimide PCBs, especially in flexible or rigid-flex formats, offer significant advantages. You can bend, twist, or fold these boards without damaging the electrical insulation or mechanical structure. This flexibility is essential for wearable electronics, medical devices, and aerospace systems where space and movement matter.

- Fr4 suits static, rigid designs with strong insulation and mechanical strength.

- Rigid polyimide adapts to complex shapes and dynamic environments, maintaining electrical insulation and reliability.

If your project needs a PCB that can flex or fit into tight spaces, rigid polyimide is the clear winner.

By understanding these material property differences, you can match the right PCB material to your project’s requirements. Consider thermal resistance, mechanical strength, chemical stability, and flexibility to ensure optimal performance and durability.

Cost Comparison

FR4 Cost Factors

You benefit from the affordability of fr4 PCBs, which makes them a popular choice for most standard electronic projects. The average manufacturing cost per square meter for fr4 is about $21.53, or $2 per square foot. This low price results from the widespread availability of materials and efficient mass production processes.

| Material | Cost per square meter | Cost per square foot |

|---|---|---|

| FR4 | $21.53 | $2 |

| Rigid Polyimide | $107.64 | $10 |

Several factors influence the final cost of fr4 PCBs:

- Materials and Components: The choice of substrate and components impacts both performance and price.

- Board Size and Complexity: Larger or more intricate boards require more resources and advanced processing.

- Production Volume: Ordering in bulk lowers the per-unit cost due to economies of scale.

- Lead Time: Rush orders increase expenses, while standard timelines save money.

- Testing and Quality Control: Additional certifications or inspections add to the total cost.

| Factor | Description |

|---|---|

| Materials and Components | Substrate and component selection affect cost and function. |

| Board Size and Complexity | Larger, complex boards need more materials and processing. |

| Quantity and Production Volume | Higher volumes reduce per-unit costs. |

| Lead Time Requirements | Faster delivery increases costs. |

| Testing and Quality Control | Extra testing raises expenses. |

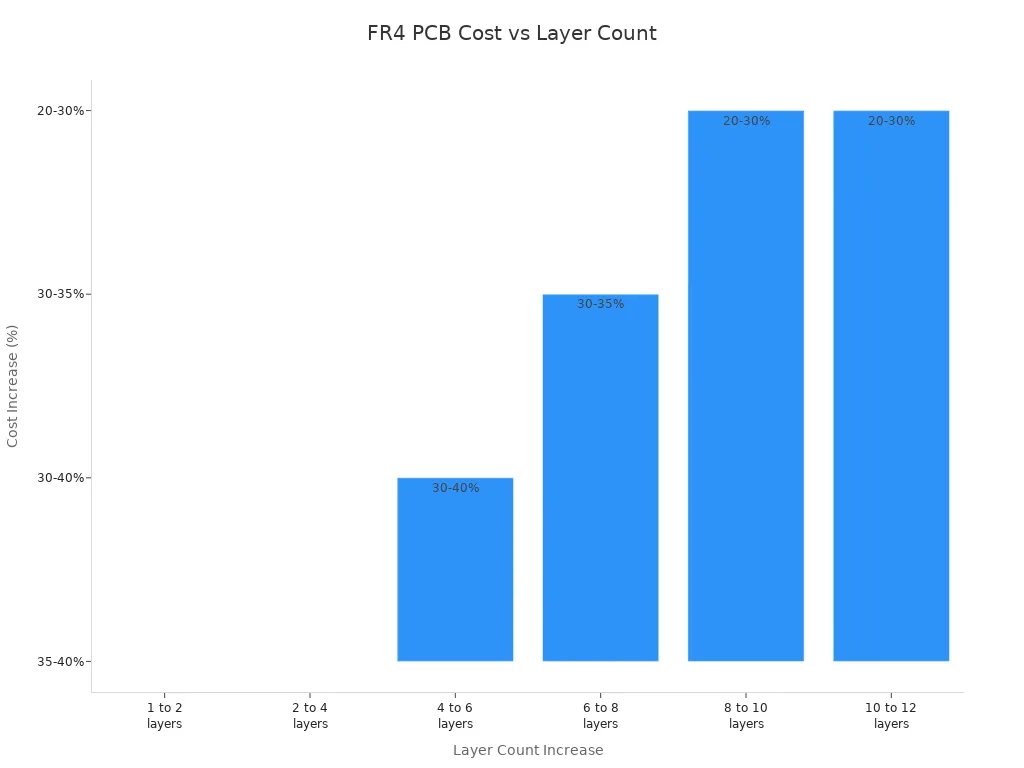

Design complexity and layer count also play a major role. As you increase the number of layers, costs rise significantly. For example, moving from a 2-layer to a 4-layer fr4 board can increase costs by 35-40%. The chart below shows how costs climb as layer count grows.

Tip: Keep your design simple and limit the number of layers to control costs when using fr4.

Rigid Polyimide PCB Cost Factors

Rigid polyimide PCBs come with a higher price tag. The average manufacturing cost reaches $107.64 per square meter, or $10 per square foot. This increase reflects the premium nature of polyimide materials and the specialized processes required.

Material costs for rigid polyimide PCBs vary by region and supplier. Factors such as thickness, flexibility, and thermal properties influence the price. Higher-quality materials improve performance but also raise production expenses. The manufacturing process for rigid polyimide PCBs involves multiple steps and specialized equipment, which adds to the cost.

Key factors affecting rigid polyimide PCB pricing include:

- Material costs fluctuate with market conditions, especially for polyimide and copper.

- Design complexity, such as intricate traces or multiple layers, requires advanced techniques and skilled labor.

- Each additional layer can increase costs by 15-25%.

- Customization for specific applications adds further expense.

- Labor-intensive manufacturing and strict quality control drive up the final price.

Note: Flexible and rigid-flex polyimide PCBs are even more expensive, with costs ranging from $0.50 to $15.00 per square inch—often two to five times higher than standard rigid designs.

You should consider these cost factors when deciding between fr4 and rigid polyimide PCBs. While fr4 offers a budget-friendly solution for most applications, rigid polyimide delivers superior performance for demanding environments at a higher cost.

Quick Reference Table

FR4 vs. Rigid Polyimide PCB

You often need a fast way to compare PCB materials before making a decision. The table below highlights the most important differences between FR4 and rigid polyimide PCBs. Use this reference to match your project requirements with the right material.

| Feature | FR4 PCB | Rigid Polyimide PCB |

|---|---|---|

| Cost | Low | High |

| Max Operating Temp | Up to 100°C | Over 250°C |

| Flexibility | Rigid | Rigid or Flexible |

| Mechanical Strength | High | Moderate to High |

| Chemical Resistance | Moderate | Excellent |

| Signal Integrity | Good | Superior |

| Typical Applications | Consumer, Industrial | Aerospace, Medical |

| Layer Count | 2-10+ | 2-20+ |

| Moisture Resistance | Good | Excellent |

| Reliability | Standard | Mission-Critical |

Tip: If your project needs to withstand high temperatures or harsh chemicals, choose rigid polyimide. For budget-friendly designs with moderate requirements, FR4 is usually the best option.

Key Points to Remember:

- FR4 suits most general electronics and offers strong mechanical support.

- Rigid polyimide excels in extreme environments and flexible designs.

- You should always consider your budget, reliability needs, and environmental conditions.

Checklist for Quick Selection:

- ✅ Need low cost? Pick FR4.

- ✅ Need high temperature resistance? Choose rigid polyimide.

- ✅ Need flexibility or mission-critical reliability? Go with rigid polyimide.

You can use this table as a starting point. Review your project’s specific needs before making a final decision.

Typical Use Cases

FR4 Applications

You encounter FR4 in a wide range of pcb applications due to its cost-effectiveness, durability, and mechanical stability. FR4 provides excellent electrical insulation properties, making it a reliable choice for many consumer and industrial electronics. You often see FR4 used in:

- Smartphones

- Tablets

- Wearable devices

- Televisions and monitors

- Gaming consoles and accessories

- Home automation and IoT devices

You benefit from FR4 in automotive and industrial environments where balanced performance is essential. FR4 pcb offers a good mix of electrical properties, thermal stability, and mechanical strength. However, you should note that in high-vibration or high-temperature settings, specialized materials may outperform FR4. Automotive systems, especially electric vehicles, require materials that can handle power loads and dissipate heat. FR4 remains the mainstream choice for most electronic applications, but you should consider the environment before finalizing your selection.

Tip: Choose FR4 when you need a rigid pcb for general electronics, where cost and reliability matter most.

Polyimide PCB Applications

You select polyimide pcb when your applications demand high reliability, flexibility, and performance in extreme environments. Polyimide excels in aerospace, defense, and medical electronics. In aerospace, polyimide pcb reduces weight by up to 60% compared to traditional rigid pcb assemblies, which improves fuel efficiency. You find polyimide in avionics, spacecraft electronics, and missile guidance systems because it withstands extreme temperatures and mechanical stress.

Medical devices benefit from polyimide pcb due to its biocompatibility and ability to conform to the human body. You see polyimide used in implantable electronics and surgical instruments, where resistance to sterilization and reliability are critical. Polyimide pcb also supports high-frequency applications, ensuring signal integrity in demanding environments.

You rely on polyimide for flex circuit and rigid-flex circuit designs. These applications require the board to bend, twist, or fold without losing performance. Polyimide pcb delivers exceptional heat resistance, robust mechanical strength, and outstanding electrical insulation. You use polyimide in flex circuit applications for wearable medical sensors, aerospace wiring harnesses, and advanced defense systems.

Note: Polyimide pcb is your go-to material for mission-critical applications, especially when you need a flex circuit or must meet strict reliability standards.

Decision Guide

Project Requirements Checklist

You can simplify your PCB material selection by using a clear checklist. This approach helps you compare FR4 and rigid polyimide PCB options based on your project’s needs. Review the table below to see how each material matches up with common requirements:

| Factor | FR4 | Rigid Polyimide |

|---|---|---|

| Operating Frequency | Suitable for low frequency | Prioritize for RF/high-frequency |

| Thermal Environment | Limited heat exposure | Ideal for high heat exposure |

| Mechanical Requirements | Rigid | Flexible |

| Budget Constraints | Cost-effective | Higher cost |

| Reliability and Lifespan | Moderate reliability | High reliability |

Use this table to quickly identify which material aligns with your application. For example, if you work in aerospace and aviation or need long-term reliability in high-temperature environments, rigid polyimide stands out.

Choosing the Right Material

You should follow a structured decision-making process to ensure the best outcome for your project. Start by defining your application requirements. Consider electrical performance, thermal performance, and mechanical performance. Evaluate cost and manufacturing process compatibility. Think about environmental concerns, especially if your design faces high-temperature environments or chemical exposure.

- List your end-use application needs.

- Assess the effort required for fabrication.

- Identify suitable materials for your requirements.

- Evaluate each option thoroughly.

- Verify that your selection meets all project needs.

If your project demands reliability in high-temperature environments, or if you design for aerospace and aviation, rigid polyimide offers unmatched long-term reliability. For most consumer electronics or cost-sensitive projects, FR4 provides a balance of reliability and affordability. Always match your choice to the reliability expectations and environmental challenges of your application.

Tip: When reliability and long-term reliability are critical, especially in high-temperature environments, rigid polyimide is the preferred choice.

You should choose FR4 for standard electronics where cost and rigidity matter most. Select rigid polyimide pcb when your project faces harsh environments, needs high reliability, or must meet a maximum continuous operating temperature. Remember, temperature and electrical properties differ between these materials. Flex offers impedance control advantages, especially in multilayer polyimide pcb and high-temperature polyimide pcb designs. For complex needs, consult PCB experts by following these steps:

- Define your application requirements.

- Evaluate cost versus performance.

- Consider long-term reliability.

- Collaborate with suppliers.

- Prototype and test.

2025-10-17

2025-10-17

BEST

BEST

.png)

.png)

.png)

.png)

.png)