When you care about your pet’s health, you know that safety matters at every step. Analytical methods help you monitor and control chemical risks in devices like Pet PCB For Pet food dispenser systems. PCBs can harm pets even at low levels, making regular testing essential. Regulatory frameworks guide you toward best practices and set standards so you can protect your pet.

Key Takeaways

- Regular testing of pet food dispensers is crucial to identify harmful chemicals like PCBs before they affect your pet's health.

- Advanced analytical methods, such as gas chromatography and improved reporting schemes, provide reliable results for detecting PCB contamination.

- Understanding the types of PCBs and their sources helps you minimize contamination risks in pet food dispensers.

- Stay informed about health risks associated with PCB exposure, including liver damage and immune suppression, to protect your pet.

- Follow safety standards and regulations, such as HACCP and CODEX guidelines, to ensure compliance and maintain trust with pet owners.

Analytical Methods for PCB Safety

Why Testing Matters

You need to understand why regular testing is crucial for pet food dispensers. Testing helps you identify harmful chemicals before they reach your pet. Scientific research shows that dioxins and pcb compounds remain a health risk. You cannot ignore the possibility of contamination.

The publication of a scientific opinion by the European Food Safety Authority (EFSA) in 2018 showed that human exposure to dioxins and PCBs continues to pose a health risk. For these reasons, we recommend to at least maintain the intensity of monitoring of dioxins and PCBs in food and feed in order to avoid the possibility of further local or even global events with increased dioxin and/or PCB concentrations.

You should maintain a strict monitoring schedule. This approach reduces the chance of unexpected spikes in pcb levels. Consistent testing protects your pet and supports industry standards.

Protecting Pet Health

You rely on analytical methods to keep your pet safe. These methods detect pcb contamination quickly and accurately. The most effective techniques use advanced technology. The table below shows two primary methods for pcb detection in pet food dispensers:

| Analytical Method | Description |

|---|---|

| Gas Chromatography | Utilizes new types of gas chromatographic separation columns for improved analysis of PCBs. |

| Improved Reporting Scheme | Enhanced method for determining all 209 PCBs, leading to lower co-elution and detailed data. |

You benefit from these methods because they provide reliable results. Gas chromatography separates pcb compounds efficiently. The improved reporting scheme gives you more detailed information about each type of pcb. When you use these tools, you make informed decisions about pet food safety.

Regular testing and advanced analysis help you prevent health problems. You protect your pet from long-term exposure to toxic chemicals. You also support a safer environment for all pets.

Understanding PCBs in Pet Food Dispensers

PCB Types and Sources

You need to recognize the different types of pcb found in pet food dispensers. Polychlorinated biphenyls include both dioxin-like and non-dioxin-like compounds. Dioxin-like pcbs pose a higher risk because they mimic the toxic effects of dioxins. Non-dioxin-like pcbs also present a risk, but their toxicity profile differs. You often encounter indicator pcbs, which help you monitor contamination levels.

Pet food dispensers can become contaminated from several sources. You may see pcb residues in recycled plastics, lubricants, or paints used in manufacturing. Environmental contamination also increases the risk. Airborne particles, dust, and water can introduce pcbs into the dispenser. You must stay alert to these sources to reduce the risk of exposure.

Tip: Always ask manufacturers about the materials and processes they use. This step helps you assess the risk of pcb contamination in your pet food dispenser.

Health Risks for Pets

You must understand the health risk pcbs pose to pets. Exposure to these chemicals can cause serious problems. Pets may develop liver damage, immune system suppression, or reproductive issues. Chronic exposure increases the risk of cancer and developmental disorders. Young animals face a higher risk because their bodies absorb toxins more easily.

The table below highlights common health effects linked to pcb exposure in pets:

| Health Effect | Description |

|---|---|

| Liver Damage | Impaired liver function and enzyme changes |

| Immune Suppression | Reduced ability to fight infections |

| Reproductive Problems | Lower fertility and birth defects |

| Cancer | Increased risk of tumors |

| Developmental Disorders | Growth and behavioral issues |

You protect your pet by staying informed about these risks. Regular testing and careful selection of dispensers help you minimize the risk and keep your pet healthy.

pet pcb for pet food dispenser: Detection Techniques

You need reliable screening methods to ensure the safety of your pet pcb for pet food dispenser. Advanced detection techniques help you identify micropollutants like dioxin and pcb compounds before they reach your pet. Regular analysis is essential because pcb levels can vary in food samples. You must understand how each technique works to choose the best approach for your needs.

GC/MS Analysis

Gas chromatography-mass spectrometry (GC/MS) stands out as a powerful tool for screening micropollutants in pet pcb for pet food dispenser systems. You use GC/MS to separate and identify both dioxin-like and non-dioxin-like pcb compounds. Dioxin-like pcbs require higher sensitivity and specificity during analysis. You often rely on high-resolution mass spectrometry (HRMS) for these compounds because the matrix is complex and the allowable limits are very low.

Non-dioxin-like pcbs can be monitored with simpler GC/MS screening methods. These methods are cost-effective and use fewer consumables. You benefit from rapid detection and accurate results. GC/MS analysis helps you meet regulatory standards and maintain the safety of your pet food dispenser.

Tip: Always calibrate your GC/MS equipment before screening. This step ensures you get reliable detection of micropollutants every time.

Indicator PCB Monitoring

You need to focus on indicator pcb monitoring when screening pet pcb for pet food dispenser systems. Indicator pcbs represent a group of compounds that signal the presence of broader contamination. You track both dioxin-like and non-dioxin-like pcbs using these indicators. Regular screening helps you spot trends and identify sources of micropollutants.

You should set up a schedule for indicator pcb monitoring. This approach allows you to respond quickly to any changes in contamination levels. You protect your pet by catching problems early. Indicator pcb monitoring supports compliance with safety regulations and helps you maintain trust with pet owners.

- Dioxin-like pcbs require more sensitive detection methods.

- Non-dioxin-like pcbs can be screened with standard GC/MS analysis.

- Indicator pcbs provide a practical way to monitor overall contamination.

Sample Preparation

You must prepare samples carefully before screening for micropollutants in pet pcb for pet food dispenser systems. Proper sample preparation improves the accuracy of detection and analysis. You start by collecting representative samples from the dispenser or pet food. You then use extraction techniques to isolate dioxin and pcb compounds.

You may need to clean up samples to remove interfering substances. This step is crucial for dioxin-like pcbs because they exist at very low concentrations. You use solid-phase extraction or liquid-liquid extraction to concentrate micropollutants. You then proceed with GC/MS analysis or other screening methods.

Note: Consistent sample preparation reduces errors and improves the reliability of your detection results.

You must repeat sample preparation and screening regularly. PCB levels can change due to environmental factors or manufacturing processes. Regular analysis helps you maintain the safety of your pet pcb for pet food dispenser and ensures compliance with industry standards.

Micropollutants like dioxin and pcb compounds pose a serious risk to pets. You need robust detection techniques and careful sample preparation to keep your pet safe. Regular screening and indicator pcb monitoring help you stay ahead of potential problems.

Safety Standards and Regulations

You must understand the safety standards and regulations that govern pet food dispensers. These frameworks help you ensure that your products meet strict safety requirements. By following these guidelines, you protect pets and maintain trust with pet owners.

HACCP and CODEX Guidelines

You should start with the Guide to Good Practice for the Manufacture of Safe Pet Foods. This guide provides a foundation for safe production. It recommends that you implement Hazard Analysis and Critical Control Points (HACCP) in your process. HACCP helps you identify hazards and control them before they become a problem.

You also need to follow the CODEX Alimentarius guidelines. CODEX sets international food safety standards. It covers everything from ingredient sourcing to final product testing. When you apply these guidelines, you create a safer environment for pets.

- HACCP requires you to monitor every step of production.

- CODEX guidelines help you align with global best practices.

- Both frameworks support compliance with regulation in the pet food industry.

Note: Regular training on HACCP and CODEX keeps your team updated on the latest safety protocols.

European Directive 2002/32/EC

You must pay close attention to European Directive 2002/32/EC. This regulation sets maximum limits for undesirable substances in animal feed, including pet food dispensers. The directive lists specific thresholds for dioxins and related compounds.

The table below shows the maximum allowable levels for dioxins and dioxin-like compounds in pet food:

| Substance | Maximum Limit (ng/kg) |

|---|---|

| Dioxins | 1.75 |

| Dioxin-like PCBs | 8.0 |

| Sum (Dioxins + PCBs) | 13.0 |

You must test your products regularly to ensure compliance with this regulation. If you exceed these limits, you risk product recalls and legal penalties. The directive also requires you to keep detailed records of your testing and corrective actions.

Tip: Always review updates to European regulations. Changes can affect your compliance status and require adjustments to your safety protocols.

U.S. and International Standards

You need to follow U.S. and international standards for pet food safety. The U.S. Food and Drug Administration (FDA) enforces strict regulation on contaminants in animal feed and pet food dispensers. The FDA sets action levels for dioxins and related compounds. You must ensure that your products do not exceed these levels.

Internationally, many countries adopt similar standards based on CODEX and European guidelines. You should check the specific regulation in each market where you sell your products. Some countries may have additional requirements for testing and documentation.

- The FDA requires you to report contamination incidents.

- International standards often mirror European and U.S. regulation.

- You must stay informed about changes in feed regulation to maintain compliance.

Callout: Staying proactive with regulation updates helps you avoid costly mistakes and protects your brand reputation.

You play a key role in upholding safety standards. By following these regulations, you ensure that pet food dispensers remain safe for every pet.

Interpreting PCB Test Results

Safe vs. Unsafe Levels

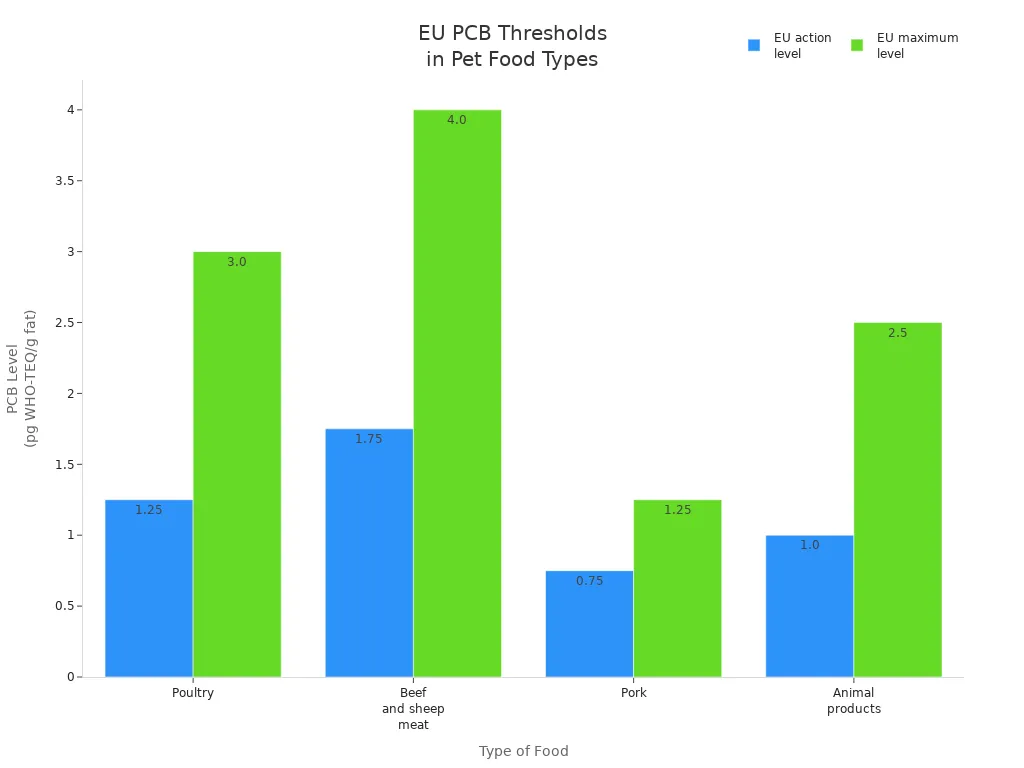

You need to interpret test results with precision to ensure pet food dispensers meet safety standards. Regulatory agencies set clear thresholds for contaminants in animal products. These thresholds help you distinguish between safe and unsafe levels. The European Union defines action and maximum levels for dioxins and related compounds in various food types. You can use the table below to compare these limits:

| Type of food | EU action level (pg WHO-TEQ/g fat) | EU maximum level (pg WHO-TEQ/g fat) |

|---|---|---|

| Poultry | 1.25 | 3.0 |

| Beef and sheep meat | 1.75 | 4.0 |

| Pork | 0.75 | 1.25 |

| Animal products | 1.0 | 2.5 |

If your test results fall below the action level, you can consider the product safe for pets. Results above the action level but below the maximum require further investigation and corrective action. Exceeding the maximum level means the product is unsafe and must not be used.

Tip: Always compare your results to the latest regulatory limits. This practice helps you maintain compliance and protect pet health.

Implications for Manufacturers and Pet Owners

You play a vital role in ensuring safety when you interpret test results. Manufacturers must act quickly if results approach or exceed regulatory limits. You need to investigate the source of contamination and implement corrective measures. Regular monitoring and transparent reporting build trust with pet owners.

Pet owners should review product safety information and choose dispensers from reputable brands. You can ask for test reports and certifications to confirm safety. Staying informed empowers you to make better choices for your pet.

- Manufacturers must document all test results and corrective actions.

- Pet owners should seek products with clear safety records.

- Both groups benefit from ongoing education about contaminant risks.

Callout: Consistent interpretation and action based on test results create a safer environment for every pet.

Best Practices for PCB Safety

Manufacturer Steps

You play a critical role in ensuring pet food dispensers remain safe. You must focus on bioaccessibility at every stage of production. Bioaccessibility testing helps you understand how much of a contaminant can actually be absorbed by pets. You should select raw materials with low bioaccessibility for harmful substances. You need to implement strict quality control measures that assess bioaccessibility during manufacturing.

You can use the following checklist to improve safety:

- Test all incoming materials for bioaccessibility.

- Use certified suppliers who provide bioaccessibility data.

- Monitor bioaccessibility throughout the production process.

- Train staff to recognize bioaccessibility risks.

- Document all bioaccessibility test results for traceability.

Tip: Regularly update your protocols to reflect new bioaccessibility research. This keeps your products ahead of safety standards.

Pet Owner Actions

You have the power to protect your pet by understanding bioaccessibility. When you choose a pet food dispenser, ask the manufacturer for bioaccessibility test results. You should look for brands that publish bioaccessibility data and explain their safety measures.

Follow these steps to keep your pet safe:

- Read product labels for bioaccessibility information.

- Contact customer service to request bioaccessibility reports.

- Clean dispensers regularly to reduce bioaccessibility of contaminants.

- Store pet food in a way that limits bioaccessibility increases from environmental exposure.

- Stay informed about bioaccessibility research and updates.

Note: Sharing your experiences with bioaccessibility and product safety helps other pet owners make better choices.

You create a safer environment for your pet when you prioritize bioaccessibility. Both manufacturers and pet owners must stay proactive and informed.

You protect your pet’s health when you use analytical methods and monitor PCB levels in dispensers. Regulatory standards, such as the EU’s strategy and Germany’s enhanced monitoring, set clear safety benchmarks.

| Regulatory Measure | Description |

|---|---|

| EU Strategy on Dioxins and PCBs | Reduces contamination in food and feed, protecting public health. |

| Maximum Levels for Dioxins and PCBs | Sets legal thresholds to harmonize safety across Europe. |

| Monitoring Requirements | Improves detection and analysis in animal feed. |

Stay proactive—test regularly, follow best practices, and choose products from brands that share safety data.

2025-10-28

2025-10-28

BEST

BEST

.png)

.png)

.png)

.png)

.png)