Printed circuit boards are the base for modern industrial automation. These systems need more than regular pcb designs. They must work in very hot or cold places. They also face lots of shaking and strong power in factories. Engineers pick special pcb types, like Flex PCB Solutions, to fix problems with signals and water. Good materials and new ways to build help each printed circuit board meet tough rules for working well and lasting long in industrial automation.

Key Takeaways

- Printed circuit boards (PCBs) are very important in factories. They help control and connect machine parts. PCBs help machines work well in hard factory places.

- Some PCBs like Flex, Metal Core, and Multi-layer boards fix problems. They help with heat, shaking, and small spaces. These boards help machines last longer and work better.

- Factories use robots and careful tests to make good PCBs. This helps stop mistakes and makes machines more reliable.

- Picking the right PCB type and class for the job is smart. It saves money and keeps machines safe and working well.

- Good PCB design and skilled partners help factories work smoothly. They lower repair costs and make upgrades easier later.

PCB Role in Industrial Automation

Integration and Control

Printed circuit boards are very important in industrial automation. They help connect and control many system parts. Engineers use pcbs to make strong and small control units. These units work well in tough factory places. Here is how pcbs help with integration and control:

- PCBs give a neat and small place for electronic parts. This helps make control systems that save space and work well.

- Good thermal management in pcbs keeps them from getting too hot. This helps machines stay safe and last longer.

- Designers can change pcbs for special jobs. This makes it easier to fit the needs of different industries.

- Box build assemblies put pcbs with wires, cases, and other things. This makes the system stronger and easier to fix.

- These things help with exact control and real-time checks in places like factories, energy, and cars.

- When pcbs and box builds work together, they make production faster, lower mistakes, and keep parts safe from tough factory conditions.

Note: Industrial pcbs are built to last a long time. They can handle heat, shaking, and even wet places. This makes them great for industrial automation.

Enabling Smart Factories

Smart factories use advanced pcbs to work better and make good products. These pcbs help teams share info and manage projects right away. Some important features are:

- Traceability during production helps track every step and keeps quality high.

- Support for real-time project software lets teams order parts and check progress without writing things down.

- Centralized info sharing helps engineers and quality teams work together.

- Data from many departments comes together to make things better and more reliable.

- Works with smart manufacturing ways, like automation and predictive maintenance.

- High precision and lots of data use at both design and production steps.

- Connects electronics and mechanics, making sure every layer fits smart factory needs.

These features help smart factories work well. They let people control things from far away, make quick changes, and improve product quality. Pcbs are a big part of these changes in industrial automation.

Industrial Automation Demands

Environmental Tolerance

Printed circuit boards in factories must handle hard places. Factories can get very hot and have lots of shaking. There are also chemicals that can hurt the boards. Engineers pick special materials and designs to keep PCBs safe. The table below shows how each solution helps PCBs last longer in tough places:

| Environmental Factor | Material/Design Solution | Description |

|---|---|---|

| High Temperatures | High-Tg FR-4, Polyimide | These materials can take heat up to 260°C. They help parts not get damaged. |

| Vibration | Thicker FR-4, Flexible PCBs | These choices soak up shocks and stop parts from breaking. |

| Moisture and Corrosion | Conformal Coatings | Special coatings keep out water and chemicals. |

| EMI | Ground planes, Shielding, EMI filters | These features lower noise and signal trouble. |

| Chemical Exposure | Chemically resistant substrates (PTFE) | These materials do not get ruined by strong chemicals. |

| Mechanical Wear | Gold and Nickel plating | These finishes stop rust and wear. They help PCBs last longer. |

PCBs also must work in very cold or hot places, from -40°C to 85°C or more. Big machines shake a lot and can break solder joints. Wet air and chemicals can hurt the board. Good design keeps the system safe and working.

Real-Time Performance

Industrial automation needs fast and correct control. PCBs help by making quick choices and keeping signals clear. Control boards handle data fast. This helps robots and machines move at the right time. Multi-layer PCBs use special cooling to stop getting too hot. Flexible PCBs keep working when robots bend and twist. Custom designs let sensors send data right away. These things help factories watch and control machines in real time.

- PCBs are used in sensors, meters, and control panels for instant feedback.

- In data centers, PCBs help networks work well, which helps real-time actions.

- Smart home and factory systems use PCBs for fast and correct control.

Protocol Support

PCBs in industrial automation must talk to many devices. They support different ways to share data, such as:

- CAN (Controller Area Network) links machines and robots.

- Ethernet is for fast data sharing in big systems.

- UART is for simple serial connections.

- SPI and I2C are for short-distance data between chips.

- USB connects and powers devices.

- Wireless options like Bluetooth and Wi-Fi are for IoT systems.

These ways help PCBs send data, check for mistakes, and keep everything working together. They make sure all parts of the system work well.

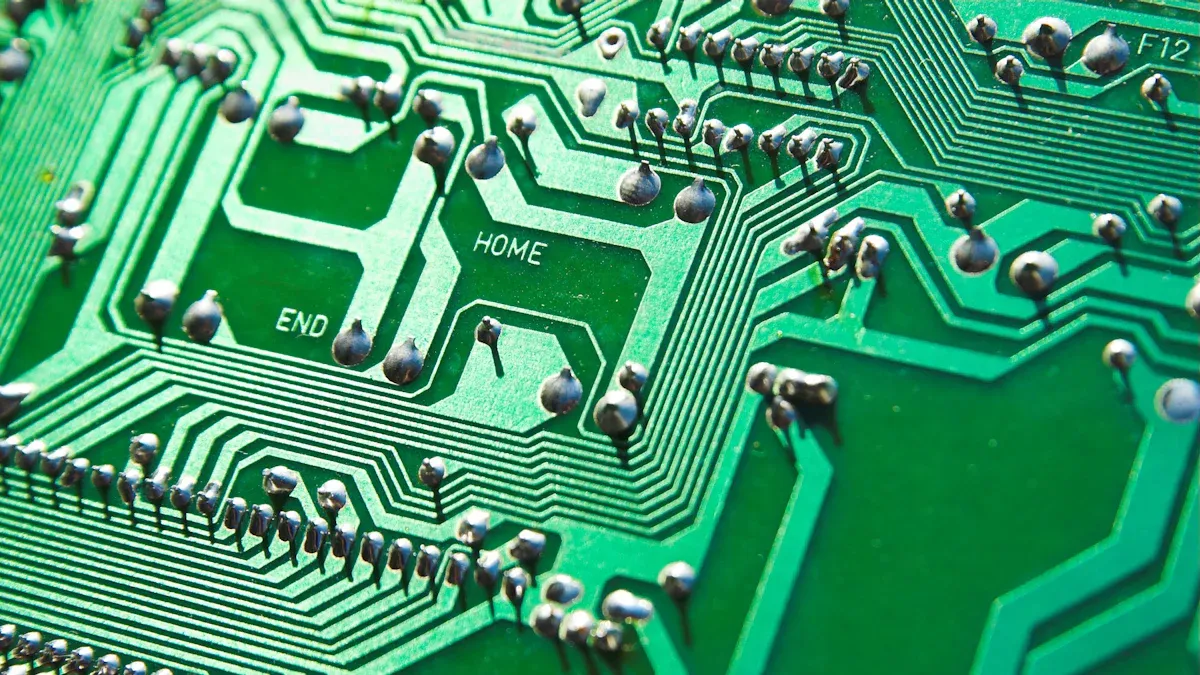

Printed Circuit Board Types and Technologies

Printed circuit board technology has changed a lot for factories. Engineers use many pcb designs and new ways to build them. This helps machines work well and last longer. The best pcb depends on the job, where it will be used, and how much trust is needed.

Rigid-Flex and Heavy Copper PCBs

Rigid pcbs use strong stuff like FR-4. These boards do not bend. They hold heavy parts and give good support. They are used in control panels and power supplies. Heavy copper pcbs have thick copper layers. This lets them carry more power and handle heat better. Factories use these boards in machines that need lots of power and run all day.

Rigid-flex pcbs mix stiff and bendy parts. The stiff parts hold big chips and connectors. The bendy parts can twist and fold. This saves space and makes the system lighter. It also helps the board last through shaking and moving. Robots and smart machines use rigid-flex pcbs. They fit in small spaces and last longer.

Note: Rigid-flex and heavy copper boards cut down on wires. They make devices stronger and help high-power machines in tough places.

Multi-Layer and Sandwich Designs

Multi-layer pcbs have three or more layers. These layers stack up like a sandwich. This lets engineers put more circuits in a small space. It also keeps signals clean and lowers noise. Multi-layer boards help with fast data and tricky chips.

- Multi-layer boards fit more parts in less space.

- Power and ground planes inside lower noise.

- Shorter traces and special layers help signals move fast.

- The sandwich build makes the board strong against heat and shaking.

- Extra copper and thermal vias spread heat and keep the board cool.

Factories use these boards in robots, sensors, and control systems. More layers cost more, but they work better and last longer for important jobs.

SMT and Through-Hole Assembly

Engineers use two main ways to put parts on a pcb. These are surface mount technology (SMT) and through-hole technology (THT).

| Aspect | SMT Advantages | SMT Disadvantages | THT Advantages | THT Disadvantages |

|---|---|---|---|---|

| Component Size & Board Space | Smaller parts, more parts per board, both sides usable | Parts are fragile, less heat tolerant, hard to fix by hand | Strong bonds, better for heat | Bigger parts, holes take space, fewer parts fit |

| Assembly Process | Fast, uses machines, saves time and energy | Needs special machines, hard to fix by hand | Easy to test and fix by hand | Slow, needs drilling, more work |

| Performance | Good for high-speed signals, less signal loss | Not as strong in tough places, parts can break | Good for tough jobs, handles heat well | Slower signals, more signal loss |

| Inspection & Testing | Hard to see and test, needs special tools | Needs costly inspection tools | Easy to see and test | Still takes time to build |

| Environmental Impact | Less waste, uses less material, energy-saving | Drilling makes waste, lead solder can harm health |

SMT lets factories build boards faster and fit more parts in less space. This is good for smart sensors and small control units. THT gives stronger joints and works better in places with lots of shaking or heat. Many industrial boards use both ways to get the best results.

PCB Classes and Their Relevance

Not all printed circuit boards are the same. The IPC sets classes for pcbs based on how much reliability is needed.

| Aspect | IPC Class 2 (Industrial Automation) | IPC Class 3 (Mission-Critical Systems) |

|---|---|---|

| Reliability | Moderate to high; allows minor defects | Zero defects; flawless solder joints |

| Materials | Standard for moderate conditions | High-grade for extreme environments |

| Testing & Inspection | Visual and AOI; less strict | Advanced tests, X-rays, stress tests |

| Environmental Suitability | Good for controlled factory settings | Handles extreme heat, shaking, moisture, chemicals |

| Manufacturing Complexity | Simpler, faster, cheaper | More complex, slower, costly |

| Typical Applications | Automation controllers, HVAC, industrial controls | Aerospace, medical, military electronics |

Class II pcbs are used in most factories. They balance cost and reliability. Class III boards are for jobs where failure is not allowed, like planes or medical tools. Class I boards are for simple gadgets and do not last as long.

Tip: Picking the right pcb class helps factories save money and keep machines safe.

PCB Type Comparison Table

| PCB Type | Features & Structure | Advantages | Limitations | Typical Applications in Industrial Automation |

|---|---|---|---|---|

| Single-sided | Traces and parts on one side | Cheap, simple | Few parts, simple jobs | Basic controls, simple devices |

| Double-sided | Traces and parts on both sides, linked by holes | More parts, better cooling | More costly, more complex | Control systems, electronics |

| Multi-layer | Three or more layers, stacked with insulation | Most parts, best signal and cooling | Expensive, hard to make | Robots, advanced controls, aerospace |

| Flexible | Thin, bendable materials | Bends, saves space, resists shaking | Fewer parts, costs more, less cooling | Sensors, small devices, cars |

| Rigid-Flex | Mix of stiff and bendy parts | Reliable, saves space, good signals | Costs more, harder to design, less bendy than pure flex | Aerospace, medical, cars |

| HDI | Tiny traces, small holes, many parts | Small size, fast data, good signals | Needs advanced tools, costs more | 5G, high-speed computing, smart cars |

This table helps engineers pick the best board for each job. They look at how tricky the system is, how much space there is, and how tough the board must be.

PCB Assembly and Quality in Automation

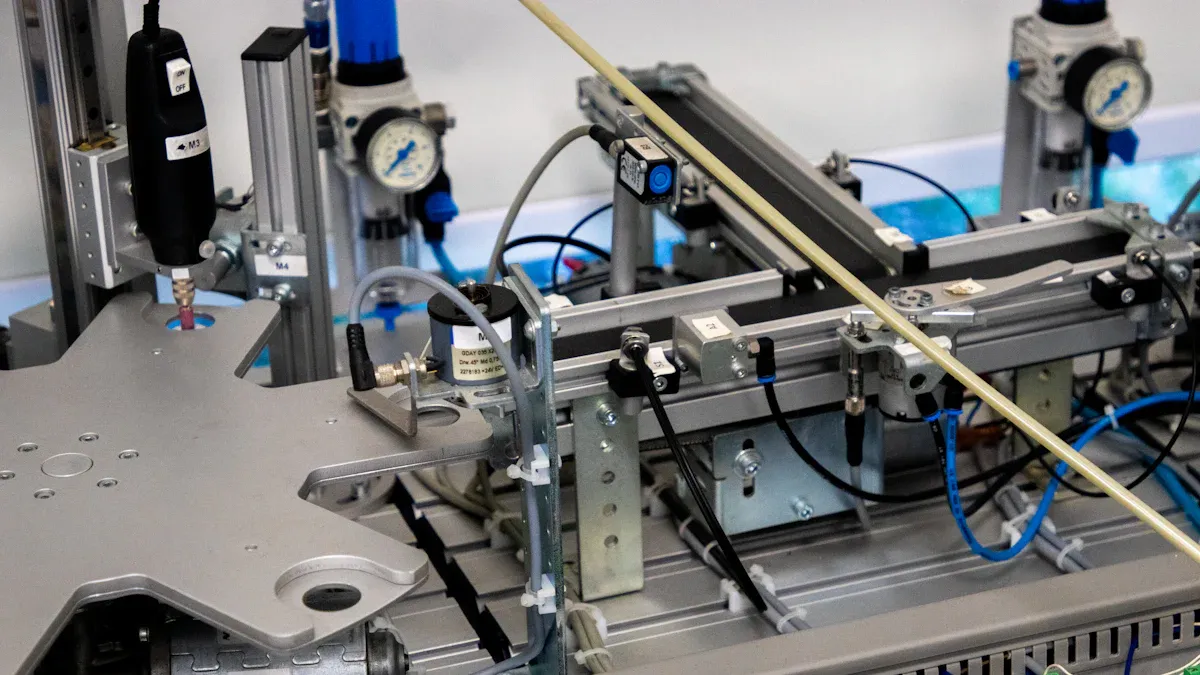

Automated Manufacturing

Factories use special machines to put together pcb assemblies. These machines work fast and place parts very carefully. They use Surface Mount Technology (SMT) for small parts on top of the board. Through-Hole Technology (THT) puts bigger parts through holes in the board.

- Robotic arms pick up parts and set them on the board.

- Reflow ovens melt solder paste to stick SMT parts in place.

- Wave soldering moves boards over hot solder for THT parts.

- AOI systems use cameras to check for missing or wrong parts.

- Flying probe tests check if the board works right.

- Cobots help people by doing easy, repeated jobs.

- Vision systems and IoT tools watch the process as it happens.

All steps follow strict rules like IPC-A-600 and RoHS. These rules help keep quality high and make sure each pcb assembly is good.

Tip: Using machines for pcb assembly lowers mistakes and makes things faster. This helps factories build strong products for hard jobs.

Testing and Reliability

Quality checks are very important in pcb assembly. Factories do many tests to find problems early and make sure boards work well.

- In-Circuit Testing (ICT) looks for open or short circuits and checks each part.

- Flying probe tests find loose wires and other electrical problems.

- Functional tests make sure the board works in real life.

- AOI systems use cameras to spot missing or wrong parts and solder issues.

- X-ray inspection finds hidden problems inside the board.

- Visual checks look for scratches or parts that are not straight.

Factories also review designs and pick strong materials for each pcb assembly. They follow rules like ISO 9001 and UL to keep quality high. Stress tests show if boards can handle heat, cold, and shaking.

A real example comes from car factories. Aluminum pcbs in electric cars made them 15°C cooler and saved energy. Another factory used aluminum pcbs for power supplies. This cut heat problems by 30% and made machines work longer. These stories show that good pcb assembly and testing help factories get better results.

Choosing PCB Solutions for Industrial Automation

Picking the right printed circuit board is important for factories. You need to think about where it will be used, how well it must work, and how much it costs. Each kind of PCB helps with different problems in factories. Engineers must choose the best board for each job.

Metal Core PCB Solutions

Metal core PCBs have a metal layer, usually aluminum or copper. This metal helps take heat away from hot parts. These boards are good for machines that run all day and get very hot.

- Metal core PCBs move heat away much faster than normal boards. Their thermal conductivity is from 1 to 7 W/m/K. Regular FR4 boards only reach about 0.3 to 0.4 W/m/K.

- The metal base makes the board strong and stiff. This helps it not break when machines shake or bump it.

- Engineers put hot parts close to the metal core. They use special materials to fill spaces and help heat move better.

- There is a layer that keeps the metal and copper circuits apart. This layer lets heat pass but stops electricity from crossing.

- These boards are tested with heat and cold to make sure they last.

Note: Metal core PCBs stop machines from getting too hot. This keeps chips safe and helps machines last longer. They are used in power supplies, LED lights, and motor drives in factories.

FR4 PCB Solutions

FR4 PCBs are made from fiberglass and epoxy. This type is used a lot in factories because it is strong, works well, and does not cost too much.

- FR4 boards keep electricity inside and do not bend easily.

- They can take high heat and do not melt or fall apart.

- Engineers use thicker copper and wider lines to help with heat. They also add holes and heat sinks to cool the board.

- FR4 does not get ruined by acids, oils, or other chemicals in factories.

- The board stays strong even if it gets hot or wet.

- FR4 PCBs follow safety rules like flame resistance and RoHS.

| Feature | Benefit in Industrial Automation |

|---|---|

| Electrical insulation | Keeps signals clear and parts safe |

| Thermal stability | Works in hot and cold places |

| Mechanical strength | Survives shocks and vibration |

| Chemical resistance | Handles oils, acids, and cleaning agents |

| Cost-effectiveness | Fits most budgets for control panels and sensors |

FR4 PCBs are found in motor controls, PLCs, and robots. They last a long time, even in hard places, and work for both easy and hard designs.

Flex PCB Solutions

Flex PCBs are made from thin, bendy stuff like polyimide. These boards fit in small spaces or where things move a lot. Factories use them in robots, sensors, and machines with moving arms.

| Scenario / Application Area | Explanation / Benefits |

|---|---|

| Industrial Electronics | Powers robotic arms and sensors where flexibility and durability are critical; supports repeated motion. |

| Durability in Harsh Environments | Withstands vibrations, shocks, and temperatures up to 400°C, suitable for industrial and aerospace uses. |

| Lightweight and Space Saving | Thin, lightweight, and foldable to fit into tight spaces where rigid boards cannot. |

| Flexibility | Can flex up to hundreds of millions of cycles, allowing installation in moving parts without failure. |

| High System Reliability | Reduced interconnection points lower failure rates; polyimide improves thermal stability. |

| High Temperature Suitability | Resistant to acids, oils, gases, and extreme heat, ideal for harsh industrial environments. |

| Cost Savings | Smaller size reduces assembly costs, testing time, and rework. |

Flex PCBs help machines work where regular boards would break. They use fewer wires and connectors, so there are fewer problems. The flexible design spreads heat out and keeps parts cool. These boards help make small, smart devices that last longer and need less fixing.

Tip: When picking a PCB, engineers should check if it can handle tough places, heat, and has safety labels. They should test for shaking, water, and chemicals. Working with good suppliers and following rules helps the board last and work well in any factory.

Printed circuit boards help make factories work better and faster. They give strong and steady solutions for machines. Companies should talk to trained PCB experts. These experts use new design tools and follow important rules. Good and matching PCBs help machines work well and break less. They also last a long time.

If you pick PCBs like an important investment, you will spend less on repairs. Your machines will run better and be easier to upgrade later. Picking the best PCB partner helps your factory do well for a long time.

2025-07-24

2025-07-24

BEST

BEST

.png)

.png)

.png)

.png)

.png)