I see the demand for flexible pcbs in China rising every year. The market reached USD 1.5 billion in 2024 and continues to grow fast.

| Metric | Value |

|---|---|

| Market size in China (2024) | $1.5 billion |

| Projected CAGR (2026-2033) | 9.2% |

| Projected market (2033) | $3.2 billion |

When I choose a flex pcb china supplier, I look for quality, experience, and innovation. Top names like BESTFPC, Zhen Ding Technology, and Unimicron Technology stand out. These companies lead the flexible pcb industry with advanced technology, reliable delivery, and strong customer support. I focus on manufacturers who understand complex flex pcb needs, offer quick turnaround, and provide flexible pcb solutions for smart devices and automotive projects.

Key Takeaways

- China's flexible PCB market is growing rapidly, expected to reach $3.2 billion by 2033 with strong demand in automotive and smart devices.

- Top manufacturers like BESTFPC, Zhen Ding Technology, and Unimicron lead with advanced technology, quality certifications, and reliable delivery.

- Choosing a supplier requires checking quality certifications, production capabilities, product range, pricing, lead times, and customer service.

- Industry trends include miniaturisation, use of durable materials, rapid prototyping, online ordering, and a focus on sustainability.

- Requesting samples and maintaining clear communication with suppliers help ensure project success and reduce risks.

Top Flex PCB China Manufacturers

Leading Companies 2025

When I look at the flex pcb china market, I see a group of companies that lead the way in technology and export volume. These manufacturers have built strong reputations for quality and reliability. Here are some of the top names I trust for flexible pcbs and automotive pcbs:

- BESTFPC: Known for expertise in polyimide flexible pcb and small-batch production.

- South-Electronic: Offers a wide range of flexible pcbs and multilayer pcbs for automotive pcbs and consumer electronics.

- Zhen Ding Technology: Ranks among the top exporters, specialising in flexible circuit boards and multilayer pcbs.

- Unimicron Technology: Delivers advanced flex pcb solutions and holds a leading position in the pcb industry in china.

- Wus Printed Circuits: Supplies high-end automotive pcbs and rigid-flex multilayer pcbs to global brands.

- Suzhou Dongshan Precision (DSBJ): Supplies flexible pcb to Apple and excels in high-volume, high-quality production.

- Kingboard Laminates: Provides materials for multilayer pcbs and flexible pcbs.

- Flex Plus (Xiamen): Focuses on custom flex pcb and automotive pcbs.

- Shenzhen Kinwong Electronic: Offers a broad product range, including flexible pcb and multilayer pcbs for automotive pcbs.

- Hitech Circuits, XPCB, Huanyu PCB, Viasion Technology, FS Technology, ELEPCB, FC Electronic, China PCB One, PCBWay, KingSong PCB Technology, Zhejiang Zapon Electronic: Each of these flexible circuit manufacturers brings unique strengths in flexible pcb, multilayer pcbs, and automotive pcbs.

| Rank | Company Name | Export Intentions (USD Billion) | Main Products |

|---|---|---|---|

| 3 | Zhen Ding Technology Holding Ltd | 4.80 | Flexible PCBs, Multilayer PCBs |

| 7 | Unimicron Technology Corporation | 8.60 | Advanced PCBs, Multilayer PCBs |

| 9 | Flexium Interconnect, Inc. | 3.70 | High-End PCBs, Flexible PCBs |

Industry Trends

I have noticed several trends shaping the flex pcb china market in 2025. The demand for flexible pcbs and automotive pcbs continues to rise, driven by new applications in electric vehicles, wearables, and medical devices. Manufacturers now use advanced materials like polyimide and polyester films, which make flexible pcb more durable and lightweight. Miniaturisation and high-density multilayer pcbs have become standard, especially for automotive pcbs and flexible displays.

Export growth stands out as a key trend. Over the past five years, China’s export volume of flexible pcbs has surged, with a 61% increase from 2023 to 2024. In October 2024 alone, exports jumped by 261% compared to the previous year. This growth confirms China’s leading role in the global flexible pcb market.

I also see more companies investing in rapid prototyping, online ordering, and turnkey solutions. These innovations help customers get custom flexible pcb and automotive pcbs faster and more efficiently. The focus on sustainability and the use of environmentally friendly processes is another important trend. As a result, the flex pcb china market remains highly competitive and continues to set new standards for flexible circuit manufacturers worldwide.

Flex PCB Selection Criteria

When I select a manufacturer for flex pcb or automotive pcbs, I always check several important factors. These criteria help me ensure that I get high-quality flexible pcbs, reliable pcba, and excellent service for my projects.

Quality and Certifications

Quality matters most in flexible pcb production. I look for manufacturers who hold recognised certifications. These show that the company follows strict quality management and safety standards. Here is a table of the most common certifications I check:

| Certification | Description |

|---|---|

| ISO 9001:2015 | Ensures consistent quality management practices across organisations. |

| IATF 16949 | Focuses on automotive pcbs, guaranteeing product quality and reliability. |

| UL | Confirms product safety through rigorous testing. |

| RoHS | Restricts hazardous substances in electronic products. |

| REACH SVHC | Ensures chemical safety for substances of very high concern. |

| CQC | Indicates compliance with Chinese quality standards. |

I always verify these certifications before placing any pcba order. They give me confidence in the flexible circuit boards I receive.

Capabilities and Technology

Production capabilities and technology set leading manufacturers apart. I want a partner who can handle complex multilayer pcbs and deliver both prototypes and mass production. Here is a comparison of what top companies offer:

| Company Name | Production Capabilities | Technological Offerings & Services | Industry Focus | Unique Strengths |

|---|---|---|---|---|

| Topfast Electronic Ltd | Rapid prototyping, high mix/low volume | Customised materials, DFM analysis, one-stop pcba | General electronics | Quick turnaround, custom solutions |

| Wintech | Custom flexible pcbs, low-mid volume | Turnkey systems, SMT, fast prototypes | Global top 500 enterprises | Complex designs, fast delivery |

| Tripod Technology | High-precision manufacturing | Strong R&D, advanced manufacturing | Automotive, medical, IoT | Innovative, reliable delivery |

I choose manufacturers who invest in advanced equipment and can support automotive pcbs, flexible pcbs, and multilayer pcbs with strong technical service.

Product Range

A broad product range means the manufacturer can meet all my needs. I prefer companies that offer flexible pcb, rigid-flex, multilayer pcbs, and pcba. Here is a table showing typical products and applications:

| Manufacturer | Main Products | Applications |

|---|---|---|

| Suzhou Dongshan Precision Mfg. | Flexible pcb, rigid-flex, multilayer pcbs, pcba | Automotive pcbs, telecom, consumer electronics |

| Zhen Ding Tech. Group | FPC, SLP, HDI, rigid-flex, pcba | Mobile, AR/VR, smart home, networking |

| Unimicron Technology Corporation | PCB, HDI, FPC, rigid-flex, pcba | Healthcare, high-speed communications |

I find that a wide product range allows me to source all my flexible pcbs and automotive pcbs from one supplier, saving time and improving service.

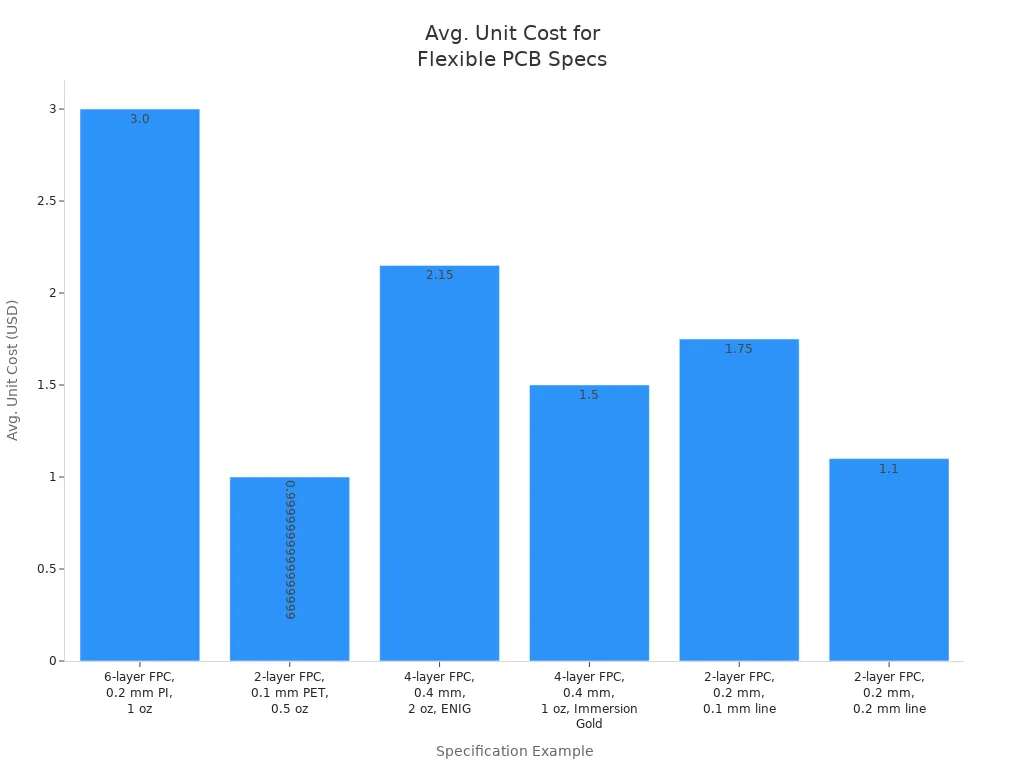

Pricing and Lead Time

Cost and delivery speed affect every project. I compare pricing models and lead times before making a decision. Here is a table that helps me understand what to expect:

| Pricing Model | Description | Cost Range (Prototype) | Cost Range (Mass Production) | Lead Time (Prototype) |

|---|---|---|---|---|

| Flat-rate Prototyping | Fixed price for small quantities | $80–$150 | N/A | 3–5 days (single-layer) |

| Custom Quote Model | For complex multilayer pcbs and rigid-flex | $200–$500 | N/A | 7–15 days |

| Mass Production Pricing | Bulk orders, economies of scale | N/A | $10–$20 per unit | Varies, often shorter |

I always plan my pcba orders to avoid rush fees and keep costs low. Bulk orders for automotive pcbs and multilayer pcbs usually offer the best value.

Customer Service

Great service makes a big difference. I look for manufacturers who provide fast responses, technical support, and regular updates. Good communication helps me avoid mistakes and ensures my flexible pcb and pcba projects run smoothly. I always request samples before large orders to check quality and service. Reliable service builds trust and long-term partnerships.

Tip: Always check for certifications, technical support, and clear communication when choosing a supplier for flexible pcbs, automotive pcbs, and multilayer pcbs. These factors protect your investment and ensure project success.

Company Profiles

BESTFPC

I have worked with BESTFPC for several years and always found their expertise in flex pcb and rigid-flex pcb impressive. They have over 20 years of experience in the industry, which gives them a deep understanding of both design and manufacturing. Their team specialises in polyimide flexible pcb, which offers excellent flexibility and thermal resistance. I appreciate that they strictly follow IPC-6013 and IPC-2223 standards, ensuring high performance and reliability for every project.

Some of the core strengths I have observed include:

- Specialisation in rigid, flex, and rigid-flex PCB technologies for enhanced durability and compact design.

- Strong expertise in material selection and quality control, especially for polyimide-based flexible pcbs.

- Support for prototype and small batch production, which helps me test new designs quickly.

- Ability to handle complex projects with tight tolerances and multiple layers.

- Rigid-flex pcbs that reduce connectors and solder joints, improving mechanical stability and reliability.

- Applications in demanding sectors like aerospace, medical devices, IoT, and consumer electronics.

Their manufacturing capabilities stand out, especially when I need quick response and on-time delivery. BESTFPC’s reputation for high quality and customer orientation makes them a top choice for flex pcb china projects.

| Aspect | Details |

|---|---|

| Certifications | ISO, IATF, SGS, UL, ISO13485, ISO9001, RoHS |

| Industry Experience | 17-20 years in Flex PCB design and production |

| Export Focus | Medical and smart wearable devices (80% of export volume) |

| Annual Export Volume | Up to 1 million pieces |

| Company Type | Chinese EMS PCB service company |

| Production Capability | One-stop production of rigid-flex PCB, multi-layer flex PCB, and special FPC boards |

| Factory Size & Staff | 3000m² factory, 200+ staff, daily peak production up to 100K pieces |

Note: BESTFPC’s ability to deliver small batches and multi-category flex pcb products with high quality and fast turnaround has earned them a strong reputation in the industry.

South-Electronic

I often recommend South-Electronic for projects that require a wide range of flexible pcbs and multilayer pcbs. Their team has built a solid reputation for delivering reliable pcba and flexible pcb solutions for automotive and consumer electronics. I value their commitment to quality and their ability to handle both large and small orders efficiently. Their customer service team responds quickly, which helps me keep my projects on track.

Zhen Ding Technology

Zhen Ding Technology stands out as a global leader in flexible pcb manufacturing. I have seen them invest heavily in research and development, which allows them to offer innovative solutions for miniaturised and high-reliability applications. Their partnerships with major OEMs help them tailor products to specific market needs. Zhen Ding’s scale and advanced manufacturing processes make them a preferred supplier for mobile phones, wearables, AR/VR, and networking equipment.

- Zhen Ding ranks as the top PCB manufacturer globally, operating under the Hon Hai Group.

- They offer a broad product range, including flexible pcbs, HDI pcbs, and rigid pcbs.

- Their focus on advanced manufacturing and one-stop pcb service supports high-demand applications.

- Major clients include Apple, which speaks to their quality and reliability.

- They accept only large-scale orders, which shows their market dominance.

| Aspect | Evidence |

|---|---|

| Market Position | Ranked as the top PCB manufacturer globally, under Hon Hai Group |

| Product Range | Offers flexible PCBs, HDI PCBs, rigid PCBs |

| Innovation Focus | Advanced PCB manufacturing, one-stop PCB service |

| Major Clients | Supplies large OEMs like Apple |

| Order Policy | Accepts only bulky orders, indicating large-scale production and market dominance |

Unimicron Technology

Unimicron Technology has a long history in the flex pcb industry, starting in Taiwan in 1990. I trust them for their focus on innovation and quality, especially in HDI and flexible pcb products. Their global supply chain network ensures reliable delivery for automotive, consumer electronics, and telecommunications projects. I have seen their products used in LCDs, smartphones, and network cards, which shows their versatility.

- Unimicron operates subsidiaries in several countries, including Vietnam, Japan, and Germany.

- They specialise in HDI, flexible, and rigid-flex pcbs.

- Their international presence and large supply chain network make them a reliable partner for global projects.

- They hold key certifications and serve a wide range of industries.

Wus Printed Circuit

When I need high-volume multilayer pcbs or advanced flex pcb solutions, I often turn to Wus Printed Circuit. Their production capacity reaches about 1.5 million square feet of pcb per month, which is impressive. They plan to expand this by 25% by the end of 2024. Their main products include double-sided, multilayer, and high-density interconnect (HDI) pcbs, as well as communication RF modules and embedded passives.

| Aspect | Details |

|---|---|

| Production Capacity | 1.5 million square feet of PCB per month |

| Planned Expansion | 25% increase by end of 2024 |

| Product Specialisation | Double-sided, multilayer, HDI PCBs, RF modules, embedded passives |

| Industries Served | Telecommunications, consumer electronics, automotive |

| Manufacturing Process | Industry 4.0, automation, IoT integration |

| Operational Efficiency | Low defect rate (0.2% vs. industry average 0.5%) |

Their use of Industry 4.0 technologies and automation ensures high efficiency and low defect rates, which I find essential for demanding pcba projects.

Suzhou Dongshan Precision

Suzhou Dongshan Precision, also known as DSBJ, has a strong legacy in flex pcb manufacturing since 1980. I rely on them for flexible pcbs, rigid pcbs, rigid-flex pcbs, and components for telecommunications and electric vehicles. Their factories in Yancheng, Zhuhai, and Suzhou allow them to serve global markets efficiently. I have seen their products used in EVs, telecom, and consumer electronics.

- DSBJ is the second-largest FPC manufacturer and third-largest PCB manufacturer globally.

- They specialise in advanced multilayer pcbs and HDI pcb design, assembly, and fabrication.

- Their acquisition of Multek has expanded their pcba capabilities with advanced SMT production lines.

- They offer comprehensive EMS solutions, including precision sheet metal and contract manufacturing.

Tip: DSBJ’s strategic partnerships and global reputation make them a reliable choice for large-scale flex pcb and pcba projects.

Kingboard Laminates

Kingboard Laminates plays a vital role in the flex pcb supply chain in China. I often source copper clad laminates from them, which are essential for manufacturing flexible pcbs and multilayer pcbs. Their operations cover over 60 manufacturing plants, and they serve industries like consumer electronics and automotive.

- Kingboard supplies flexible copper clad laminates, a key material for flex pcb products.

- Their business includes single, double, multi-layer, and HDI pcbs.

- I trust their materials for consistent quality in my pcba projects.

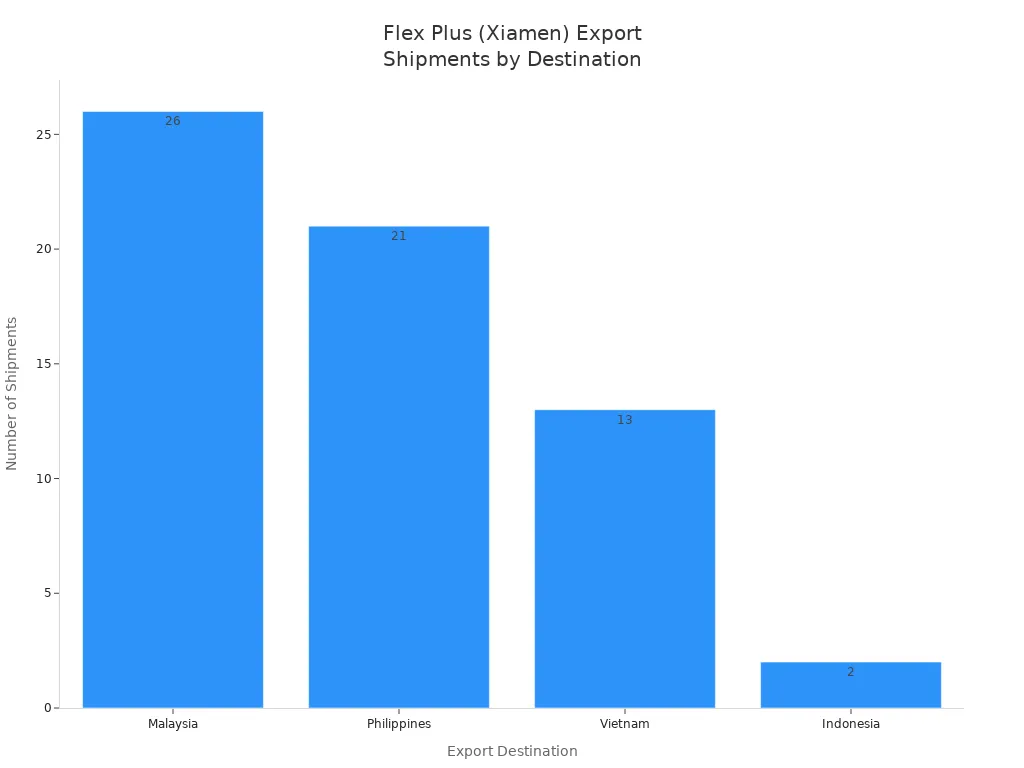

Flex Plus (Xiamen)

Flex Plus (Xiamen) offers a broad range of flexible pcb products, including single-sided, double-sided, multi-layer, and rigid-flex pcbs. I value their focus on high-quality and cost-effective manufacturing. Their certifications include ISO9001:2005, IATF16949, ISO 13485:2016, UL, and ISO14001:2015. Their products serve medical, automotive, EV, communication, and mobile phone industries.

Their export destinations include Malaysia, Philippines, Vietnam, and Indonesia, with Malaysia accounting for the largest share.

I have found their flexible pcb solutions reliable for both domestic and international projects.

Shenzhen Kinwong Electronic

Shenzhen Kinwong Electronic has built a strong reputation for quality and delivery reliability, especially in the automotive pcb market. I have seen their products used by major brands like Tesla and SAIC Volkswagen. Their automotive electronics revenue makes up about 24% of total revenue, and they have reported significant growth in recent years.

Kinwong operates 11 production bases and employs over 15,000 staff. Their certifications include ISO9001, ISO14001, and UL, and they comply with RoHS standards. I appreciate their strong R&D team and robust quality control system, which ensures high-quality pcba and multilayer pcbs for demanding applications.

Hitech Circuits

Hitech Circuits specialises in express prototype pcb assembly services. I often use their services when I need rapid turnaround for complex pcb fabrication and assembly. Their experienced team manages everything from fabrication to assembly in-house, which saves me time and reduces errors.

- They handle prototype volumes of 1-50 pieces, ideal for quick design evaluation.

- Their strengths include competitive pricing, fast quotes, and high-quality production.

- Hitech Circuits focuses on rapid electronics manufacturing, helping me bring products to market quickly and cost-effectively.

- They offer design for manufacture (DFM) and design for testing (DFT) services, even for high-density multilayer pcbs.

XPCB

XPCB provides a wide range of flexible pcbs and multilayer pcbs. I have used their services for both prototypes and mass production. Their team offers strong technical support and quick response times, which helps me meet tight deadlines. They focus on quality and reliability, making them a good choice for pcba projects that require precision.

Huanyu PCB

Huanyu PCB offers a comprehensive range of products, including rigid pcbs, metal core pcbs, flexible pcbs, HDI pcbs, high-frequency boards, and ceramic substrates. I rely on their electronic manufacturing services for design, component procurement, SMT, DIP, testing, and assembly.

- Their certifications include ISO9001, ISO14001, TS16949, and UL approval.

- They use high-quality materials from well-known brands.

- Multiple production bases and advanced equipment ensure consistent quality for my pcba and multilayer pcbs.

Viasion Technology

Viasion Technology focuses on custom flexible pcb and multilayer pcbs. I have found their team responsive and willing to accommodate special requirements. Their flexible pcb solutions are suitable for medical, industrial, and consumer electronics. I appreciate their attention to detail and commitment to quality in every pcba order.

FS Technology

FS Technology offers one-stop pcba services, including flexible pcbs, rigid-flex, and multilayer pcbs. I often use their turnkey solutions for rapid prototyping and mass production. Their team provides strong technical support and quick delivery, which helps me manage complex projects efficiently.

ELEPCB

ELEPCB provides flexible pcb, rigid-flex, and multilayer pcbs for various industries. I value their focus on quality and customer service. Their team supports both small and large orders, making them a flexible partner for my pcba needs.

FC Electronic

FC Electronic delivers a wide range of flexible pcbs and multilayer pcbs. I have used their services for both prototypes and mass production. Their team offers reliable quality and fast turnaround, which is important for my time-sensitive pcba projects.

China PCB One

China PCB One specialises in flexible pcb and multilayer pcbs. I appreciate their ability to handle complex designs and provide quick quotes. Their team supports both domestic and international customers, making them a versatile partner for pcba projects.

PCBWay

PCBWay is well-known for its online ordering platform and rapid prototyping services. I often use their platform for quick quotes and fast delivery of flexible pcbs and multilayer pcbs. Their customer service team responds quickly, which helps me resolve issues and keep my pcba projects on schedule.

KingSong PCB Technology

KingSong PCB Technology offers a broad range of flexible pcbs, rigid-flex, and multilayer pcbs. I trust their team for high-quality production and reliable delivery. Their technical support helps me solve design challenges and optimise my pcba projects.

Zhejiang Zapon Electronic

Zhejiang Zapon Electronic provides flexible pcbs and multilayer pcbs for automotive, medical, and consumer electronics. I have found their team responsive and committed to quality. Their flexible pcb solutions meet strict industry standards, making them a reliable partner for pcba and flex pcb products.

How to Choose a Flex PCB Manufacturer

Assessing Needs

When I start a new project, I always match my requirements to the strengths of different pcb manufacturers. I look for advanced technical capabilities, such as multilayer flex circuits, high-density interconnects, and ultra-thin designs. I check for certifications like ISO 9001 and UL, which show a commitment to quality and safety. I also want a manufacturer who can support rapid prototyping and scale up to volume production without losing quality. Turnkey assembly and online ordering platforms with real-time quoting make the process smoother. Reliable turnaround times, competitive pricing, and strong after-sales service are essential for every pcba project.

Here are the key factors I consider:

- Technical capabilities for complex designs

- Certifications and quality standards

- Ability to handle both prototypes and mass production

- Turnkey assembly and engineering support

- Transparent pricing and responsive service

- Proven delivery reliability

Comparing Companies

I compare companies using a structured approach. First, I gather recommendations and research online. I screen candidates based on their manufacturing capabilities, certifications, and experience. I prepare a detailed request for quotation, including technical specs and lead times. I always evaluate samples for quality and consistency. I use a comparison table to assess each supplier objectively.

| Criteria | Why It Matters |

|---|---|

| Certifications | Ensures quality and safety |

| Manufacturing capability | Supports complex pcba requirements |

| Pricing | Balances cost and value |

| Delivery reliability | Keeps projects on schedule |

| Service and support | Solves issues quickly |

I also check if the company offers testing and debugging, as well as secure packaging and shipping. These steps help me choose the right partner for flexible pcbs and pcba service.

Communication

Clear communication makes every pcba project easier. I look for companies that respond quickly and provide regular updates. Good communication helps me solve problems early and avoid misunderstandings. I always ask for a dedicated point of contact. This ensures I get fast answers and reliable service throughout the project.

Tip: Strong communication builds trust and leads to better results in every pcba service.

Requesting Samples

I never skip the step of requesting samples or prototypes. Prototyping lets me check the manufacturer's workmanship and quality before mass production. I examine the build quality, component placement, and test the functionality. This step helps me spot issues early and ensures the final pcba meets my needs. By reviewing samples, I reduce the risk of defects and costly mistakes.

Note: Always request samples to confirm the manufacturer's capability and the quality of their service.

I have found that the best flex PCB companies in China for 2025 each offer unique strengths, from advanced technology to reliable service. To choose the right partner, I always:

- Check supplier track record and certifications for reliability.

- Review delivery performance and quality control processes.

- Assess communication and flexibility in service.

- Match my project’s flex pcb needs with the supplier’s expertise.

By focusing on quality, strong service, and clear communication, I ensure my projects succeed.

2025-07-23

2025-07-23

BEST

BEST

.png)

.png)

.png)

.png)

.png)