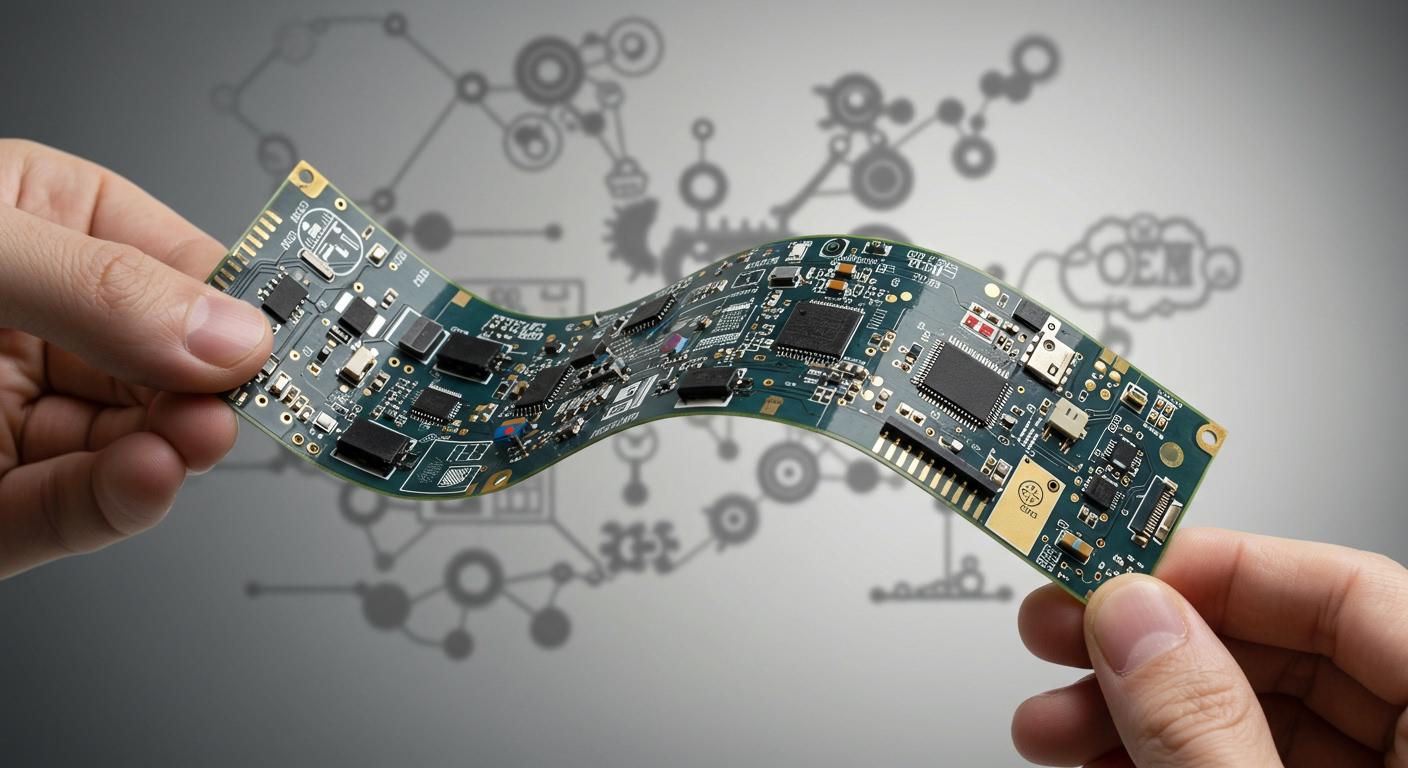

You rely on OEM flexible circuits when you need custom electronic solutions that combine reliability and versatility. These circuits fit into tight spaces and withstand harsh environments, making them ideal for modern designs. Many industries choose flexible circuits because they bend, twist, and integrate into complex products while producing almost no waste.

- The automotive sector uses OEM flexible circuits to improve electric and autonomous vehicle designs.

- Medical device manufacturers trust flexible circuits for advanced, lightweight equipment.

| Reliability Metric | OEM Flexible Circuits (Rigid-Flex) | Traditional Rigid PCBs |

|---|---|---|

| Connection Reliability | Fewer connectors, reducing failure points | More connectors, higher failure risk |

| Flex Cycle Durability | Designed for repeated flexing | Limited flexing capability |

| Environmental Resistance | Better suited for harsh environments | Less resistant to environmental stress |

| Lifespan | Generally longer due to fewer failure points | Shorter lifespan due to more potential failure points |

Key Takeaways

- OEM flexible circuits offer reliability and versatility, making them ideal for tight spaces and harsh environments.

- Different types of flexible circuits, like single-sided and double-sided, provide unique advantages for various applications.

- Choosing the right supplier is crucial; look for quality certifications and strong customer support to ensure reliable products.

- Implement best practices during design and manufacturing to enhance the performance and longevity of flexible circuits.

- Stay informed about the latest technologies and trends in flexible circuits to maintain a competitive edge in your designs.

Flexible Circuit Systems

Flexible circuit systems give you the freedom to design electronic products that fit unique shapes and demanding environments. You can choose from several types, each offering distinct advantages for your application. The following table summarizes the main types of flexible circuits used in electronics manufacturing:

| Type of Flexible Circuit | Description |

|---|---|

| Single-sided flex circuits | Have a conductor layer made of metal or conductive polymer on a flexible dielectric film. |

| Double access/back-bared flex | Allow access to selected features of the conductor pattern from both sides. |

| Sculptured flex circuits | Involve a multi-step etching method yielding conductors with varying thickness along their length. |

| Double-sided flex circuits | Feature two conductor layers and can be fabricated with or without plated through holes. |

Single Side Flexible PCB

Single side flexible PCBs offer a straightforward solution for many OEM applications. You work with a single conductive copper layer on a flexible dielectric substrate. This design keeps manufacturing simple and cost-effective. You can use single side flexible circuits in devices where space is tight and flexibility is critical.

Tip: Choose single side flexible PCBs for applications that require maximum flexibility and minimal complexity.

When you compare single side flexible PCBs to double side flex PCBs, you notice several performance differences:

| Aspect | Single-Sided Flexible PCBs | Double-Sided Flexible PCBs |

|---|---|---|

| Component Placement | Limited space due to circuitry on one side | More efficient use of space with components on both sides |

| Flexibility | Greater flexibility due to simpler construction | Slightly stiffer due to the second layer of substrate |

| Manufacturing Complexity | Simpler to manufacture | More complex due to circuitry on both sides |

| Cost | Cheaper due to simpler structure | More expensive due to added complexity |

| Design Flexibility | Limited design options | More complex interconnects and better signal integrity |

You often see single side flexible circuits in consumer electronics, sensors, and basic flex print applications.

Double Side Flex PCB

Double side flex PCBs provide you with more design options and improved signal integrity. You get two conductive copper layers, one on each side of the flexible substrate. This structure allows you to place components on both sides, making better use of available space.

- You can route more complex interconnects.

- You achieve better electrical performance.

- You support higher-density designs.

Double side flexible circuits suit applications where you need moderate flexibility and increased functionality. You find them in medical devices, automotive electronics, and advanced flexi-circuits.

Multilayer Flexible Circuits

Multilayer flexible circuits take your design capabilities to the next level. You work with three or more copper layers separated by thin polyimide films. This configuration lets you accommodate high-density components and add more functions to your product.

- You benefit from very fine lines, which enable high board density.

- You leave room for additional components and features.

- You solve complex routing challenges in compact spaces.

Multilayer flexible circuits are ideal for sophisticated devices such as smartphones, tablets, and aerospace systems. You can meet demanding electrical requirements and ensure reliable performance in harsh environments.

Rigid-flex PCB

Rigid-flex PCBs combine the best features of rigid and flexible printed circuit boards. You integrate rigid sections for component mounting and flexible sections for dynamic bending. This hybrid design reduces the number of connectors, cables, and solder joints, lowering the risk of mechanical failure.

- You eliminate traditional interconnect points, which are common failure sources.

- You use durable materials like polyimide to withstand harsh environments.

- You achieve long-term reliability in mission-critical applications.

Rigid-flex PCBs endure high-shock loads, making them suitable for military, aerospace, and industrial systems. You can trust these boards to deliver consistent performance over time.

Note: When designing flexible circuits, pay attention to technical flexibility, layer usage, component positioning, trace routing, operating environment, and electrical requirements. These factors ensure your flexible circuit system meets OEM standards and performs reliably.

Flexible Flex Circuit Design

Flexible Circuit Design Supplier-BESTFPC

When you select a supplier for flexible circuit design, you want a partner who delivers consistent quality and reliability. BESTFPC stands out by focusing on strict quality control and customer satisfaction. You can evaluate their performance using several key criteria:

| Criteria | Description |

|---|---|

| On-time delivery rates | You receive your orders on schedule, with rates above 97%. |

| Reorder rates | High reorder rates show that clients trust and return for more business. |

| Response times | You get answers to your questions in under three hours, ensuring smooth communication. |

| ISO certifications | You benefit from international quality standards in every product. |

| RoHS compliance | You meet environmental regulations and avoid hazardous substances. |

| Production capacity | You can scale your projects thanks to large factory size and skilled workforce. |

| Quality verification | You can request samples to check impedance control, bend endurance, and layer alignment. |

Tip: Always ask for product samples before placing a large order. This step helps you verify the supplier’s quality and ensures the circuits meet your technical requirements.

Flex Circuit Manufacturers

You have access to a global network of leading flex circuit manufacturers. These companies drive innovation and set industry standards. When you choose a manufacturer, you benefit from their expertise, advanced technology, and commitment to expanding flexible electronics portfolios.

- Samsung Group (South Korea)

- LG Corp. (South Korea)

- Panasonic Corporation (Japan)

- The 3M Company (US)

- Konica Minolta Inc. (Japan)

- First Solar, Inc. (US)

- E Ink Holdings (Taiwan)

- BEST Technology Ltd. (CN)

- Blue Spark Technologies, Inc. (US)

- BrightVolt Technologies (US)

These manufacturers distinguish themselves by launching new products, investing in research, and meeting the demands of diverse industries. You can rely on their flexible circuits for applications in consumer electronics, automotive, medical devices, and more.

Flexible Circuit Technologies

You can unlock new possibilities in product design by using the latest flexible circuit technologies. Flexible PCBs allow you to create intricate layouts and shapes that rigid boards cannot match. You can bend, twist, and fit circuits into tight spaces, which opens the door to innovative product development.

Some of the most common flexible circuit technologies include:

- Coils for wireless charging and signal transmission

- Sensor components for real-time monitoring and data collection

- Electrodes for neuro-stimulation and medical applications

You also see flexible circuits used in:

- Smartphones, tablets, and wearable devices

- Automotive electronics for advanced driver assistance systems

- Lightweight, bendable designs that support miniaturization and multifunctionality

Recent innovations have pushed the boundaries even further:

- Embedded passive technology integrates resistors and capacitors directly into the circuit, saving space.

- Flex-to-install components simplify assembly and improve reliability.

- 3D flexible circuits enable you to design products with complex, three-dimensional shapes.

You can choose from single-layer flex circuits for medical biosensors or multi-layer flex circuits for RF antennas and high-frequency applications. Each technology offers unique benefits, allowing you to tailor your design to your specific needs.

Note: By staying informed about the latest flexible circuit technologies, you ensure your products remain competitive and meet the highest industry standards.

Flexible Circuits Applications

You see oem flexible circuits driving innovation across many industries. Their adaptability and reliability make them essential for advanced product designs.

Medical Devices

You rely on flexible circuits for medical devices that demand precision and durability. These circuits power wearable monitors, implantable sensors, and diagnostic equipment. You find them in:

- Continuous glucose monitors and heart rate trackers

- Pacemakers and cochlear implants

- Flexible endoscopes and portable ultrasound probes

- Wearable electrotherapy and drug delivery systems

- Minimally invasive surgical tools and robotic surgery systems

- Flexible ECG electrodes and remote monitoring devices

You must ensure these circuits meet strict standards, including ISO 13485:2016 certification and FDA registration. Manufacturers also follow IPC performance specifications to guarantee safety and reliability.

Automotive

You use oem flexible circuits to improve safety and efficiency in vehicles. Their lightweight design helps boost fuel economy and extend battery life in electric cars. You benefit from circuits that withstand temperature changes, humidity, and vibrations. Flexible circuits fit into tight spaces for sensors, enhancing accuracy and reducing electromagnetic interference. You also see them in LED lighting systems, which save space and improve heat dissipation.

Consumer Electronics

You experience flexible circuits in everyday devices. They enable slim, lightweight designs for wearables, smartphones, and tablets. You find them in:

- Printers and speakers

- PCs and TVs

- Lighting and cameras

- Controls, touch screens, and touch pads

Flexible circuits support advanced features and compact layouts, making electronics more user-friendly and reliable.

Industrial

You depend on flexible circuits for industrial automation and control systems. These circuits power robotics and motion control, allowing smooth movement and signal flow. In industrial IoT, flexible PCBs collect real-time data in harsh environments. Control panels use flexible circuits for compact designs and fewer cabling errors.

| Manufacturer | Specialty Areas |

|---|---|

| TTM Technologies, Inc. | Fixed and flexible PCBs, backplane assembly, electro-mechanical systems. |

| Nippon Mektron Ltd. | Single-sided and double PCBs. |

| DSBJ | Quality focus, AI diversification, industry expertise. |

| Tripod Technology | Rigid and flexible PCBs, electronic back-end equipment, high-quality production. |

| Kinwong | Collaborative design and production, high-quality PCB goods and services. |

| Unimicron Technology Corporation | Rigid-flex PCBs, integrated circuit carriers, HDI, testing, and burn-in services. |

| Zhen Ding Technology Holdings Co., Ltd. | Carrier board SLP, Rigid PCB RCB, Flexible circuit board FPC, HDI, Module Product. |

| RayMing PCB & Assembly | Full turnkey services, customized flex circuit boards. |

| Hemeixin Electronics Ltd. | Rigid and flexible PCB solutions adhering to quality standards. |

You can select a manufacturer based on your application needs and specialty requirements.

Choosing a Provider

Evaluation Criteria

Selecting the right supplier for oem flexible circuits requires careful evaluation. You want a provider who can deliver consistent flex circuit quality and meet your technical needs. Consider these key criteria:

| Criteria | Description |

|---|---|

| Manufacturing Capacity, Equipment, and Technology | Check if the provider can handle your production volume and uses advanced technology like SMT and THT. |

| Experience in Handling Specific Types of PCBs | Make sure the supplier has experience with the exact type of flexible or multilayer circuits you need. |

| Quality Certifications and Standards | Look for ISO 9001, ISO 14001, RoHS, CE Marking, and UL Certification to ensure compliance. |

| Customer Support and Communication | Assess their ability to provide clear updates and after-sales support. |

| Cost vs. Quality Balance | Weigh the price against the quality offered to avoid future issues. |

You benefit from working with providers praised for reliability and advanced manufacturing. Ms. Carlen Shu and Ms. Angela Her both recommend Omni PCB for their high-quality flexible circuits and excellent customer service.

Design Support

You need strong design support when developing new products with oem flexible circuits. Top providers offer a range of services to help you avoid costly mistakes and speed up development.

| Service Type | Description |

|---|---|

| OEM PCB Design | Production based on your original drawings and materials. |

| ODM PCB Design | Custom design services using your application parameters. |

| OEM FPC Routing | Processing and production after you submit design files. |

| 3D PCB Display | Structural checks to identify defects before manufacturing. |

| Workshop on Design Errors | Immediate solutions for any design errors found. |

| Faster Turnaround | Quick fixes for design or material issues, often within 1-2 days. |

Providers who offer workshops and 3D displays help you catch problems early. You save time and reduce risk by choosing a supplier with these capabilities.

Implementation Tips

You improve your results by following best practices during implementation. Use these tips to maximize reliability and performance:

- Size pads and coverlay openings to allow adhesive squeeze out.

- Stagger traces across layers in double-sided flex circuits to reduce tension.

- Use hatched polygons for power or ground planes to maintain flexibility.

- Avoid placing vias in flex areas unless necessary, and keep them clear of rigid-to-flex interfaces.

- Terminate cutouts and slots with circular sections or relief holes to prevent tearing.

You may face challenges like material selection and manufacturing processes. Providers use additive manufacturing and specialized encapsulation to protect circuits. Alternative interconnection methods, such as chip-on-flex, also boost reliability.

Tip: Always communicate your requirements clearly and request prototypes before full production. This step helps you verify flex circuit quality and ensures your design meets expectations.

You gain significant value and versatility from OEM flexible circuits. To select the right solution, follow these steps:

- Identify your material needs, such as polyimide or copper foils.

- Review design requirements for reliability and manufacturability.

- Confirm that your chosen fabricator can handle complex designs.

| Strategy | Importance |

|---|---|

| Design support | Prevents costly rework and improves engineering outcomes. |

| IPC 2223 standards | Ensures reliable material selection and construction. |

| Budgetary quotes | Helps you manage costs and optimize production choices. |

| Manufacturing location | Influences speed and cost advantages. |

| Certifications | Guarantees compliance with project requirements. |

Explore new trends, including miniaturization, advanced materials, and automation. You can unlock innovative solutions by researching providers and assessing your needs. Start your journey toward flexible circuit excellence today.

2025-09-28

2025-09-28

BEST

BEST

.png)

.png)

.png)

.png)

.png)