You have many options when picking an fpc maker in 2025. The market for flexible printed circuit board makers is getting bigger. This is because industries like consumer electronics and automotive want better products.

- The global fpcb market size is about USD 23.89 billion in 2024.

- It may grow to USD 50.90 billion by 2030.

- The expected CAGR from 2025 to 2030 is 13.7%.

Big printed circuit board makers like AT&S and BESTFPC. try to give better service choices. You should check design support, prototyping, and assembly when you compare companies. This helps you choose the best one for your project.

Key Takeaways

- The flexible printed circuit board market is growing fast. It may reach USD 50.90 billion by 2030.

- When you pick an FPC maker, look at what they do best. Check their quality standards. Think about how much they can make. See what support services they offer.

- Big companies like Nippon Mektron and Zhen Ding Tech. Group are famous for new ideas. They are also known for being reliable in making FPCs.

- Find companies that give many services. These should include design, prototyping, assembly, and packaging. This will help make your project easier.

- Always look at prices and ask for a full price list. This helps you get the best deal for your flexible printed circuit board needs.

Top FPC Makers

Leadership Criteria

It is important to know what makes a company special. You want a manufacturer that fits your project and gives good quality. The table below shows what you should check when you compare flexible printed circuit board manufacturers:

| Criteria | Description |

|---|---|

| Specialization | Manufacturers should match your product needs, like rigid, flex, or HDI substrates. |

| Quality Standards | Look for certifications such as ISO 9001 and UL for good quality. |

| Production Volume | Think about if the manufacturer does high-volume or small batch jobs. |

| Lead Times | Pick manufacturers with fast turnaround if you need speed. |

| Technological Capabilities | Advanced skills are needed for hard jobs like microvias. |

| Support and Communication | Good customer service and clear communication help your project. |

Use these points to compare printed circuit board manufacturers. This helps you find the best flexible printed circuit board makers for your needs. You can see which ones have the right skills, quality, and support.

Leading Brands Overview

There are many top flexible printed circuit board manufacturers in the market. Some brands are famous for their new ideas, trustworthiness, and service. Here is a list of top flexible printed circuit board manufacturers you should know:

- Nippon Mektron

- Zhen Ding Tech. Group

- Interflex

- Nitto Denko

- MFLEX

- Career

- Flexium

- Si Flex

- Wintech

- BESTFPC

- Abis Circuits Co., Ltd.

- AirBorn, Inc.

- Alper S.R.L.

- Amphenol Corporation

- AT & S Austria Technologie & Systemtechnik Aktiengesellschaft

- BHflex Co., Ltd.

- ES&S Solutions GmbH

- Eurocircuits GmbH

- ExPlus Co., Ltd.

- Fralock Holdings, LLC

- Fujikura Ltd.

- Ichia Technologies Inc.

- Jinghongyi PCB (HK) Co., Limited

- Mekoprint A/S

- Multek Corporation

- NOK Corporation

- Schweizer Electronic AG

- Shenzhen Kinwong Electronic Co., Ltd.

- Sumitomo Electric Industries Ltd.

- Tech Etch, Inc.

- Tianjin Printronics Circuit Corp.

- TTM Technologies, Inc.

- Würth Elektronik eiSos GmbH & Co. KG

These manufacturers lead the market because they use advanced technology, give strong support, and make high-quality products. Many of these printed circuit board manufacturers have big market shares and work with many industries.

Let’s see what makes some of these top flexible printed circuit board manufacturers special. The table below shows the main strengths and new ideas of a few leading brands:

| Company Name | Unique Strengths and Innovations |

|---|---|

| Nippon Mektron | Started in 1969, known for new ideas, many electronic products, and good manufacturing. |

| Zhen Ding Tech. Group | Began in 2006, known for many product types like flexible printed circuits and high-density boards. |

| Interflex | Makes many FPCB products, known for being reliable and using advanced technology. |

| MFLEX | Started in 1984, focuses on research and development to stay ahead in technology. |

Nippon Mektron has a long history and is good at new ideas. Zhen Ding Tech. Group makes many kinds of pcb products, including high-density boards. Interflex is known for reliable work and advanced technology. MFLEX spends money on research and development to stay ahead.

These top flexible printed circuit board manufacturers set high standards for others. You can trust them for quality, speed, and support. Many other pcb manufacturers also give good service and advanced skills. You should look at their strengths and pick the one that fits your needs.

If you want the best flexible printed circuit board manufacturers, check their specialization, quality standards, and support. Use the points and brand list above to help you choose. The right fpc maker will help you get the results you want for your project.

Service Offerings

When you pick an fpc maker, check their services. The best companies help you from start to finish. They support design, prototyping, assembly, packaging, and turnkey solutions. Let’s look at these services so you know what they do.

Design and Prototyping

Your flexible pcbs should work well for your project. Top companies help with design and fast prototyping. They use smart tools for high-density flex circuits and high-density interconnect boards. You can get quick prototypes, small batches, and even 3D printing.

Here is a table that shows what top makers offer for design and prototyping:

| Manufacturer | Services Offered |

|---|---|

| Rayming | Rapid prototyping, high-speed precision prototyping |

| PCBA Now Inc. | High precision PCB prototyping services |

| BEC Manufacturing | Quality-focused, sustainable solutions |

| Global Well PCBA | Design, fabrication, assembly, quick-turn prototyping |

| Elecrow | PCB Prototyping, Assembly, Flexible PCBs, 3D Printing |

You can also get these services:

- Rapid prototyping

- Quick-turn prototyping (done in 48 hours)

- Flexible, rigid-flex, and multilayer boards

- Component sourcing

- Acrylic laser cutting

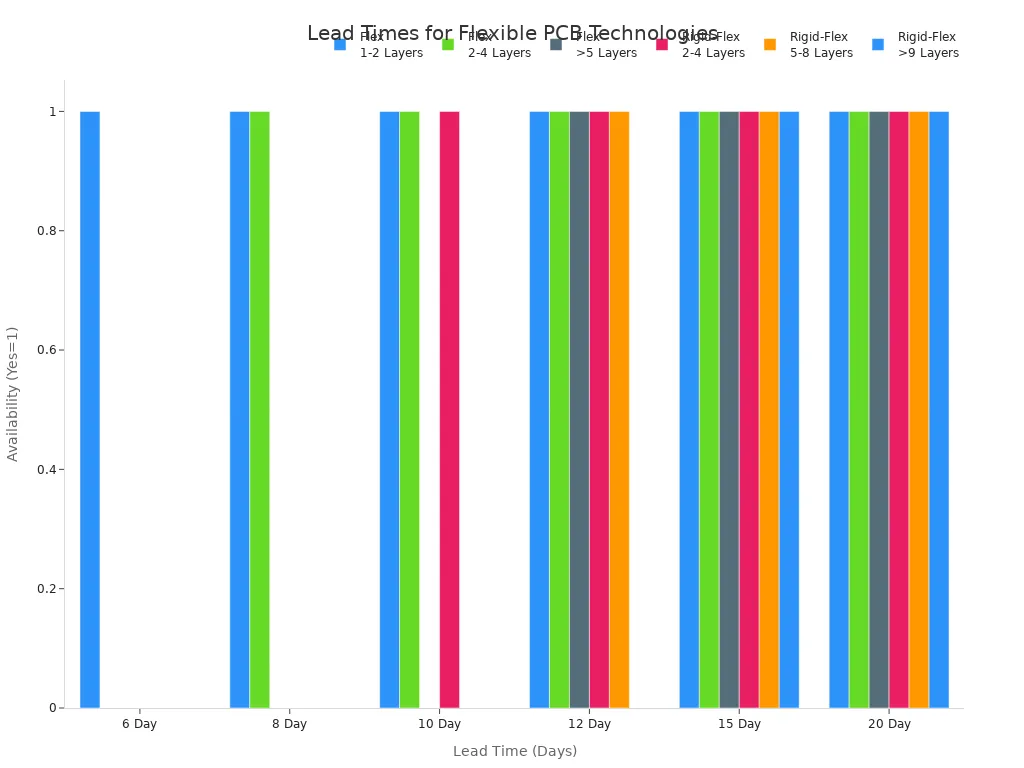

Lead times are important if you need your fpcb quickly. Some factories in China finish parts in 7 days. A Dallas factory can deliver big orders in 10 days. This depends on how hard and good the job is. You can use split deliveries and stocking programs for big orders.

Assembly and Packaging

After design and prototyping, your boards need to be put together and packed. Top makers use smart technology for assembly. You get flexible pcbs, rigid-flex, and automotive-grade boards. Companies like South-Electronic and Amkor Technology do high-performance assembly for many industries.

Here is a table that compares assembly and packaging skills:

| Manufacturer | Specialization | Technologies Offered |

|---|---|---|

| South-Electronic | Telecom, automotive, consumer products | Flexible, rigid-flex, automotive-grade PCBs |

| Amkor Technology | Outsourced packaging and test services | IC packaging, test services, strategic manufacturing |

| JCET Group Co., Ltd. | Semiconductor assembly and test | Wafer-level packaging, SiP, flip-chip |

| Huatian Technology | Advanced semiconductor packaging | SiP, TSV, Fan-Out, Wafer-Level Packaging |

You want your flexible printed circuit board to arrive safely. Makers use moisture barrier bags, desiccants, and high-density foam. These keep your boards safe from shocks, vibration, and moisture. You also get vacuum packaging, antistatic trays, humidity cards, and clear labels for date and amount. This protects your flexible pcbs during shipping and meets world standards.

- Vacuum packaging

- Low adhesion packaging material

- Standard and special vacuum trays

- Cardboard between each piece

- Humidity indicator card

- Production date and quantity labels

Turnkey Solutions

If you want things easy, look for turnkey solutions. These services cover everything from start to finish. You get design, development, making, assembly, and support all together. This saves time and helps you avoid mistakes.

Wintech and RayMing PCB are great for turnkey services. They handle every step so you can focus on your project. Other companies also offer full or part turnkey solutions. Here is a table that shows what you get:

| Manufacturer | Services Offered |

|---|---|

| PFC | Full turnkey for flexible circuits, design, development, manufacturing, assembly, customer support |

| Technotronix | Custom Flex PCB fabrication, design to production, quality and cost optimization |

| Best Flexible Circuits | Consignment, full and partial turnkey assembly, design, prototyping, procurement, quality control |

You can pick turnkey services for high-density flex circuits, high-density interconnect boards, and more. This makes your project faster and easier.

Tip: If you want less stress and more speed, turnkey solutions from Wintech or RayMing PCB can help you finish your flexible printed circuit board project on time.

Price Comparison Summary

When you look at flexible printed circuit board manufacturers, check their prices. Prices can be very different from one company to another. You should think about the board type, size, and how many layers it has. These things help you find the best price for your project.

Pricing Models

Flexible printed circuit board manufacturers use different ways to set prices. Some charge for each board. Others give prices for big orders or whole projects. The table below shows how prices change when you buy more boards:

| PCB Type | Cost per Unit Range (Low Volume) | Cost per Unit Range (Bulk) |

|---|---|---|

| Single-Layer PCBs | $1 to $5 | Below $1 |

| Double-Layer PCBs | $1 to $10 | Varies |

| Multi-Layer PCBs | $10 to $20 | 20-50% reduction possible |

| Advanced PCBs | > $50 | Varies |

If you order a lot of boards, the price for each one goes down. Printed circuit board manufacturers give discounts for big orders. This helps you save money if you need many boards.

You can also look at prices for different board types and sizes. Here is another table to help you:

| PCB Type | Size | Price Range (Low Volume) |

|---|---|---|

| Rigid FR-4 PCB | 4-layer 6"x4" | ~$30 per square inch |

| Flexible Polyimide | 4-layer 6"x4" | $150 to $300+ per square inch |

| Rigid PCB | 12"x18" 8-layer | ~$150 |

| Flexible PCB | 12"x18" 8-layer | Starts at $1,500 and can exceed $3,000 |

Flexible printed circuit board manufacturers charge more for flexible boards. Special materials and hard designs make the price higher.

Cost Transparency

Printed circuit board manufacturers show you what makes up the price. You see costs for materials, work, and other fees. Flexible printed circuit board manufacturers use very thin materials, which cost more than regular ones. If the design is hard or has many layers, the price goes up.

If you order a lot, your cost can go down. Small orders cost more because setup takes time and money. Machines can help make boards faster, but they cost more at first.

Different industries need different prices. Consumer electronics want low prices. Aerospace needs boards that work very well. This changes how printed circuit board manufacturers set their prices.

Tip: Always ask flexible printed circuit board manufacturers for a full price list. This helps you compare and pick the best choice for your project.

Quality and Certifications

Standards

You want your flexible printed circuit board manufacturers to follow strict rules. Top printed circuit board manufacturers get global certifications to prove their quality. These standards help you get good pcbs for your projects. Here is a table with important certifications from leading flexible printed circuit board manufacturers:

| Certification Type | Details |

|---|---|

| IPC Certifications | IPC 6013 type 4 class 3 & (S), IPC 6012 Class 3 & 3S, IPC 1791 Trusted Electronics QML |

| ISO Certifications | ISO 9001, AS9100D, MIL-PRF-31032, ITAR Registered |

Some certifications matter most to customers. For example, PICA Manufacturing Solutions has UL 796 and IPC 6013 certifications. These show they care about quality and reliability.

Flexible printed circuit board manufacturers use these standards for their quality checks. You can trust your boards will work for important jobs.

Compliance

Printed circuit board manufacturers must follow rules for each industry. You need to check if your pcb manufacturers meet the right standards for your field. Here is a table with key standards and what they focus on:

| Standard | Description | Key Focus Areas |

|---|---|---|

| UL 796 | Safety of flexible printed circuits | Flammability, MOT, CTI |

| IPC 6013 | Performance for flexible wiring | Reliability in tough conditions |

| ISO 13485 | Medical device quality management | Risk management, validation |

| IPC Class 3 | High-performance/critical systems | Tight tolerances, strict inspection |

| FDA 21 CFR 820 | Medical device quality system | Design controls, corrective actions |

| RoHS | Restriction of hazardous substances | Limits on toxic materials |

| REACH | Chemical safety in manufacturing | Chemical transparency |

| ISO/TS 16949 | Automotive quality management | Defect prevention, waste reduction |

| AEC-Q100 | Automotive integrated circuit qualification | Durability in harsh environments |

| IPC-6012 | PCB design and fabrication guidelines | Material and testing requirements |

Flexible printed circuit board manufacturers must meet ISO 13485 for medical devices. They also need ISO/TS 16949 for cars. RoHS and REACH help protect the environment. Many printed circuit board manufacturers use eco-friendly materials and lean manufacturing. They design boards to be recycled and use less material. This helps keep the planet clean.

Note: If you pick flexible printed circuit board manufacturers with strong quality and compliance, you get products that work well for your industry.

Choosing FPC Maker

Project Needs

First, think about what your project needs before you choose an fpc maker. Flexible printed circuit board manufacturers have many choices, but not all are right for every job. Here are the main things to think about:

- You want your final product to work well. Pick printed circuit board manufacturers who make high-quality fpcb.

- Make sure flexible printed circuit board manufacturers can change designs for your needs.

- Skilled workers are important. They help fix hard design problems.

- Good storage keeps your fpcb safe after it is made.

- Ask for clear prices so you do not spend too much.

- Choose printed circuit board manufacturers who help you at every step.

Tip: If you need fast samples or small orders, ask about quick-turn services and batch options. This helps new companies and R&D teams test ideas fast and change designs without spending a lot.

Application Fit

Flexible printed circuit board manufacturers make products for many uses. You should pick service offerings that match your project. The table below shows how top printed circuit board manufacturers help different jobs:

| Application Area | Technical Advantages | Key Applications |

|---|---|---|

| Consumer Electronics | High-density interconnects, 100,000+ bend cycles | Foldable smartphones, convertible laptops |

| Medical Devices | Biocompatible, resists fluids and heat, 1M+ flex cycles | Hearing aids, endoscopes, pacemakers |

| Automotive Applications | Handles 20G vibrations, extreme temperatures, reduces vehicle weight by 10% | Sunroofs, airbag systems, EV battery management |

Check if flexible printed circuit board manufacturers have worked in your industry. For example, cars need boards that last in tough places. Medical devices need boards that are safe and always work.

Support

Support from printed circuit board manufacturers makes your project easier. Look for flexible printed circuit board manufacturers who give:

- Help with design and making sure your board can be built.

- Free checks for design and files before making your board.

- 24/7 tech support if you have urgent questions.

- Full quality checks with many inspections.

- Fast samples and help after you buy.

Printed circuit board manufacturers who do these things help you avoid problems like hard designs, picking the wrong materials, and testing issues. You get better boards and finish faster.

Note: If you have questions or special needs, talk to flexible printed circuit board manufacturers. Good support helps you fix problems and finish your project on time.

You can find many differences between flexible printed circuit board manufacturers. Every company has its own products, uses, and strengths.

| Manufacturer | Main Products | Applications | Advantages |

|---|---|---|---|

| Nippon Mektron, Ltd. | Single-sided FPC, Double-sided FPC, Multi-layer FPC | Automotive, Medical Devices, Robotics | New ideas in stretchable and very flexible FPCs |

| Yougn Poong Electronics | Flex PCB, Multi-layer PCB | Display, Automotive | Makes cheaper parts and stretchable FPCs |

| Unimicron Technology | HDI PCB, Rigid-Flex PCB | Consumer Electronics, Healthcare | Uses advanced ways to package products |

Pick printed circuit board manufacturers that match what you need. Startups like fast prototyping and small orders. Big companies want full service and certified quality. R&D teams need special features and good support. Use price and service points to get the best deal and quality.

The industry is changing to smaller parts, flexible PCBs, and smarter ways to make things. You get new benefits as printed circuit board manufacturers use AI, better materials, and 3D printing.

2025-09-25

2025-09-25

BEST

BEST

.png)

.png)

.png)

.png)

.png)