Rigid flex manufacturing is changing fast with new technology. Better materials and robots make the process more precise and quick. For instance, laser drilling creates tiny holes with great accuracy. HDI designs allow smaller boards that do more tasks. These improvements cut down waste and help the environment. As more people need circuit boards for IoT and medical tools, rigid-flex tech keeps improving. It provides strong and flexible solutions for today’s needs.

Key Takeaways

- Rigid-flex PCBs mix hard and bendable materials. They work well for small and tricky electronic designs.

- New tools like laser drilling and HDI make smaller boards. These boards waste less and work better.

- AI design tools help by doing tasks automatically. This makes designing faster and reduces mistakes in making PCBs.

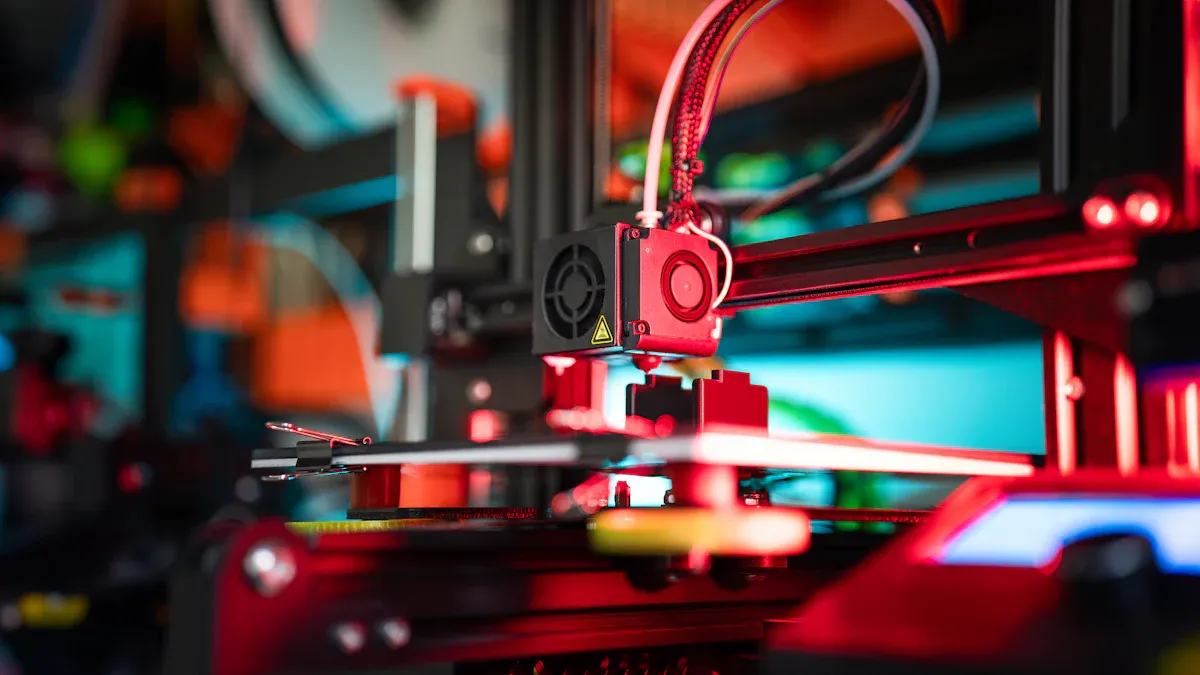

- 3D printing is cheap for testing ideas. It lets people create cool designs without costly molds.

- Rigid-flex PCBs save money over time. They use fewer parts and are easier to put together.

Overview of Rigid-Flex PCB Manufacturing

What Are Rigid-Flex PCBs?

Rigid-flex PCBs mix strong rigid boards with bendable flexible ones. These designs have stiff parts joined by flexible layers. This makes them fit well into tricky electronic systems. They are used where space is tight and bending is needed. Unlike regular PCBs, rigid-flex boards can bend into 3D shapes. This reduces the need for extra connectors and wires.

The demand for rigid-flex PCBs is growing worldwide. By 2033, their market value may hit $3,777.5 million. Industries like aerospace, medical tools, and electronics drive this growth. Asia-Pacific leads, holding 75% of the market share. This shows how important rigid-flex PCBs are becoming in many fields.

Why Are Rigid-Flex PCBs Important?

Rigid-flex PCBs are key to modern gadgets. Their special design gives many benefits like better reliability, lighter weight, and flexible use. They help make small devices work well without losing quality. These boards are also tough, perfect for aerospace and military needs.

Rules ensure rigid-flex PCBs meet high standards. For example, IPC-2292 lists rules for design and materials. IPC-6013 checks their performance to keep quality high. These rules make sure rigid-flex PCBs work well in different uses.

In electronics, they help create slim phones and smartwatches. In medical tools, they power tiny, precise machines. Their ability to adapt makes them a must-have for advanced technology.

Latest Technologies in Rigid-Flex PCB Manufacturing

Advanced Materials for Better Strength

The materials used in rigid-flex PCBs are very important. New polyimide films and strong adhesives improve their durability. These materials help the boards handle heat and wear better. This makes them great for tough jobs in aerospace and cars.

High-frequency PCBs also gain from these new materials. They have low signal loss and work well at high speeds. This is crucial for devices like medical tools and communication systems.

Tip: Pick materials that are both strong and flexible. This keeps the boards durable and working well.

Laser Drilling for Tiny Holes

Laser drilling has changed how small holes are made in PCBs. It is very precise and can make tiny holes as small as 0.005 inches. It also cuts production time by half compared to older methods. This means fewer mistakes and better results.

Here’s a quick look at what laser drilling can do:

| Metric | Value |

|---|---|

| Microvia Size | As small as 0.005 inches |

| Capture Pad Size | As small as 0.003 inches |

| Depth-to-Diameter Ratio | Up to 15:1 |

| Trace Resolution | Up to 3 mils (0.076 mm) |

| Yield Improvement | Aiming to double soon |

Using laser drilling helps make smaller, better PCBs with fewer errors. This is especially useful for electronics where size and reliability matter.

HDI for Smaller Boards

High-Density Interconnect (HDI) is key for modern PCB designs. It allows more wires in less space, making boards smaller but more powerful. This is helpful for medical tools, car electronics, and gadgets.

For example:

- A medical company made smaller diagnostic tools with HDI.

- A car electronics maker improved driver systems using HDI.

- A tech brand used HDI to create thinner smartphones.

HDI saves space and improves how boards work. It reduces signal problems and makes boards more reliable. With HDI, you can build smaller, better devices without losing quality.

AI-Driven Design Tools for Better Results

AI tools are changing how rigid-flex PCBs are designed. They make the process faster and more accurate. These tools study past data to suggest the best ways to connect parts, place layouts, and route wires. By automating tasks, they reduce mistakes and save time.

AI also helps reuse old designs smartly. It suggests rules based on past work and tech needs. This reduces manual work and ensures designs meet standards. AI can even create layouts automatically, cutting down errors from manual work.

Here’s how AI tools improve PCB design:

| Feature | Benefit |

|---|---|

| Schematic Connections | AI picks parts and links them, saving time and avoiding mistakes. |

| Reusing Designs | Old designs are reused, making work faster and more efficient. |

| Rule Suggestions | AI gives rules based on past work, reducing manual input. |

| Layout and Routing | AI finds the best layout and wire paths using past data. |

| Checking and Testing | AI checks designs and suggests fixes for better accuracy. |

| Auto Layout Creation | AI makes layouts automatically, saving time and reducing errors. |

Using AI tools means faster designs, fewer mistakes, and better layouts for rigid-flex PCBs.

3D Printing for Prototypes and Parts

3D printing is changing how rigid-flex PCBs are made. It allows for creative designs and saves money. You can make detailed prototypes and parts without needing costly molds. This is great for small production runs.

Selective Laser Sintering (SLS) 3D printing is special. It creates complex designs with less waste. It works well for high-frequency PCBs by improving signal flow. While traditional methods give smoother surfaces, 3D printing is better for the environment because it reuses materials.

Here’s a comparison of SLS 3D printing and traditional methods:

| Feature | SLS 3D Printing | Traditional Methods |

|---|---|---|

| Cost | Cheaper for small batches | Expensive due to mold costs |

| Surface Quality | Rougher finish (Ra: 6–12 µm) | Smoother finish (Ra: <1.6 µm) |

| Design Options | Allows complex, custom designs | Limited by mold shapes |

| Speed | Slower for big batches | Faster for mass production |

| Environmental Impact | Less waste, more material reuse | More waste, less reuse |

With 3D printing, you can make prototypes faster, cut costs, and try new ideas for rigid-flex PCBs.

Robots for Faster Production

Robots are improving rigid-flex PCB manufacturing by working faster and more accurately. They handle tricky tasks and keep quality consistent. Robots with predictive maintenance can fix problems before they happen, reducing downtime.

Automation boosts production time by 60%. Most robotic arms now have predictive maintenance, which helps avoid delays and keeps production running smoothly.

| Feature | Value |

|---|---|

| Uptime Improvement | 60% |

| Predictive Maintenance Use | 90% |

By using robots, you can make products faster, lower costs, and ensure better quality in rigid-flex PCB manufacturing.

Benefits of These Technologies

Better Performance and Reliability

New methods make rigid-flex PCBs work better and last longer. These updates help devices handle tough conditions and stay reliable. Testing proves these improvements are effective.

| Test Type | What It Checks |

|---|---|

| Thermal Cycling Test | How PCBs handle repeated heating and cooling. |

| Thermal Shock Test | If PCBs survive sudden temperature changes. |

| Solder Mask Dissolution Test | Resistance to chemicals and heat during soldering. |

| Acid and Alkali Resistance Test | PCB strength in harsh chemical environments. |

These tests show rigid-flex PCBs are strong and dependable. They are perfect for important uses like satellites and medical tools. For example, a satellite maker used them to save space and lower costs. This shows how these technologies help in big industries.

Lower Costs Over Time

Rigid-flex PCBs cost more to make at first but save money later. Their simple design means fewer parts and no extra connectors. This lowers assembly costs. Their toughness also reduces repairs and downtime.

- Fewer parts make assembly easier and cheaper.

- Strong design means fewer breakdowns and less fixing.

- Industries like aerospace and cars benefit from long-term savings.

Investing in these PCBs saves money without losing quality. They are a smart choice for both small and big projects.

More Flexible Designs

New ideas in rigid-flex PCB making allow creative and compact designs. Flexible PCBs mix strong rigid boards with bendable ones. This makes them great for tricky electronics.

- Loose-leaf stack-ups improve design options.

- Automation and AI tools help create better designs.

- Flexible PCBs work well for wearables, offering comfort and strength.

These updates let you make PCBs for many uses, like gadgets or factory machines. Flexible designs keep your products ahead in a fast-changing market.

Reduced Weight and Space Requirements

Making electronics lighter and smaller is very important today. Flexible PCBs help achieve this by mixing rigid and bendable layers. This removes the need for big connectors and cables. It makes devices weigh less and take up less space.

Flexible PCBs let you build small gadgets that still work well. They can bend to fit tight spaces, which is great for wearables, medical tools, and aerospace systems. For example, in wearables, their light weight makes them comfy but still strong.

These boards allow creative designs that rigid ones can't do. You can make 3D shapes that fit into tricky spaces. This is useful for industries like cars and electronics, where every gram and millimeter matter.

Lighter Flexible PCBs also save energy. Smaller devices need less power, so batteries last longer. This is helpful for IoT gadgets, which need to work for a long time.

- Tip: Use lightweight materials and smart layouts for better space and performance.

By using Flexible PCB technology, you can create products that are smaller, lighter, and more efficient. This keeps your designs ahead in a market that wants new and practical ideas.

Industry Applications of Rigid-Flex PCBs

Aerospace and Defense

Rigid-flex PCBs are very important in aerospace and defense. They work well in tough conditions, making them great for satellites, planes, and military tools. These boards are strong and small, helping to save weight and space in high-tech systems.

In aerospace, they fit into tight spaces for advanced systems. In defense, they make communication devices and radar systems more reliable. Their tough design handles heat and shocks, which is crucial for important missions.

Tip: Use materials that resist heat and vibration for better durability in aerospace and defense projects.

Medical Devices

Medical tools need to be precise and reliable, and rigid-flex PCBs help with both. These boards allow smaller designs, like health monitors and implantable devices. Their flexible structure fits into complex layouts, making them ideal for advanced medical tools.

Rigid-flex PCBs are also durable, handling frequent use and harsh conditions like sterilization. They simplify assembly, speeding up production for life-saving devices.

| Key Drivers | Description |

|---|---|

| Device Miniaturization for Electronics | Smaller, lighter devices are in demand, especially in wearables and medical tools. |

| Healthcare Electronics | Reliable, compact devices like implantable tools and health monitors are increasingly needed. |

Consumer Electronics

Consumer gadgets depend on rigid-flex PCBs for their flexibility and performance. These boards help make thinner phones, lighter laptops, and smaller wearables. Combining flexible and rigid parts makes assembly easier, cutting costs and boosting efficiency.

The need for portable devices is growing, increasing the use of flex PCBs. Smaller designs require high-density PCBs, which save space and last longer. Rigid-flex PCBs let you create detailed layouts that work well without losing quality.

| Aspect | Description |

|---|---|

| Design Flexibility | Combines flexible and rigid parts for creative layouts. |

| Durability | Strong boards that work well in tough conditions. |

| Space-Saving Potential | Compact designs save room in devices. |

| Reduced Assembly Complexity | Easier assembly with fewer parts needed. |

Note: Flexible PCB tech is key for making modern consumer gadgets better and smaller.

Automotive Industry

Rigid-flex PCBs are very important for car electronics. They are used in systems like ADAS, infotainment, and EV parts. These boards mix rigid and flexible layers, making them small and strong. They fit into tight spaces while staying durable.

Car electronics must follow strict safety rules. Rigid-flex PCBs meet standards like IPC-6012 and ISO 26262. They work well in tough conditions like heat, vibration, and moisture. This makes them great for engine controls and battery systems. Below are key rules for using rigid-flex PCBs in cars:

| Standard | What It Covers |

|---|---|

| IPC-A-600G | PCB looks, size, layout, and surface details. |

| IPC-6012 | Quality rules for rigid and rigid-flex PCBs. |

| ISO 26262 | Safety rules for car electronics. |

| AEC-Q100/AEC-Q200 | Tests for reliability of car electronic parts. |

| JESD22-A100 | Stress tests for electronics, like vibration and moisture. |

| IEC 61508 | Safety rules for car electronic systems. |

| UL 94 | Checks how materials burn in car PCBs. |

| RoHS | Bans harmful materials to protect health and nature. |

Using rigid-flex PCBs in cars improves safety and performance. They save space and weight while lowering costs and making assembly easier.

Industrial Equipment and IoT Devices

Industrial machines and IoT gadgets need strong and flexible PCBs. Flexible PCBs are great because they bend and fit into small spaces. They are perfect for IoT sensors and factory machines.

In factories, flexible PCBs handle heat, vibration, and chemicals well. For IoT devices, they help make lightweight and energy-saving designs. For example, they are used in smart sensors for factories or wearables for health tracking. Their small size removes the need for big connectors, saving space and boosting performance.

IoT demand has improved flexible PCB technology. HDI designs allow smaller boards with more features. These PCBs also improve signals, helping devices connect better in IoT systems.

Flexible PCBs are ideal for modern industrial and IoT needs. They are strong, adaptable, and help create new and better designs.

New tools like laser drilling, HDI, AI, and 3D printing are changing how rigid-flex PCBs are made. These updates make boards more accurate, faster to produce, and allow for creative designs that fit today’s needs.

- Using these new methods keeps you ahead in a fast-changing market. They make products work better, cost less, and inspire fresh ideas.

Learn how these advanced tools can solve your production problems and help you succeed. The future of electronics relies on adopting these powerful technologies.

FAQ

1. Why are rigid-flex PCBs better than regular PCBs?

Rigid-flex PCBs are strong and can bend. They need fewer connectors and wires, saving space and weight. Their 3D bending ability makes them perfect for small designs in aerospace, medical tools, and gadgets.

2. How does laser drilling help in making PCBs?

Laser drilling makes tiny holes very accurately. It speeds up production and reduces mistakes. This helps create smaller, more reliable PCBs, which are important for modern, compact electronics.

3. Can AI tools make PCB design easier?

AI tools help by automating tasks like layouts and error checks. They use past data to suggest better designs. This saves time, reduces errors, and makes production faster and more accurate.

4. Is 3D printing good for making many PCBs?

3D printing is great for testing and small batches. It allows creative designs and uses less material. But for making many PCBs quickly, traditional methods are better. Use 3D printing for unique and eco-friendly ideas.

5. Which industries use rigid-flex PCBs the most?

Industries like aerospace, medical tools, cars, and IoT depend on rigid-flex PCBs. These boards are strong, flexible, and save space, making them perfect for satellites, health devices, and electric cars.

2025-05-28

2025-05-28

BEST

BEST

.png)

.png)

.png)

.png)

.png)