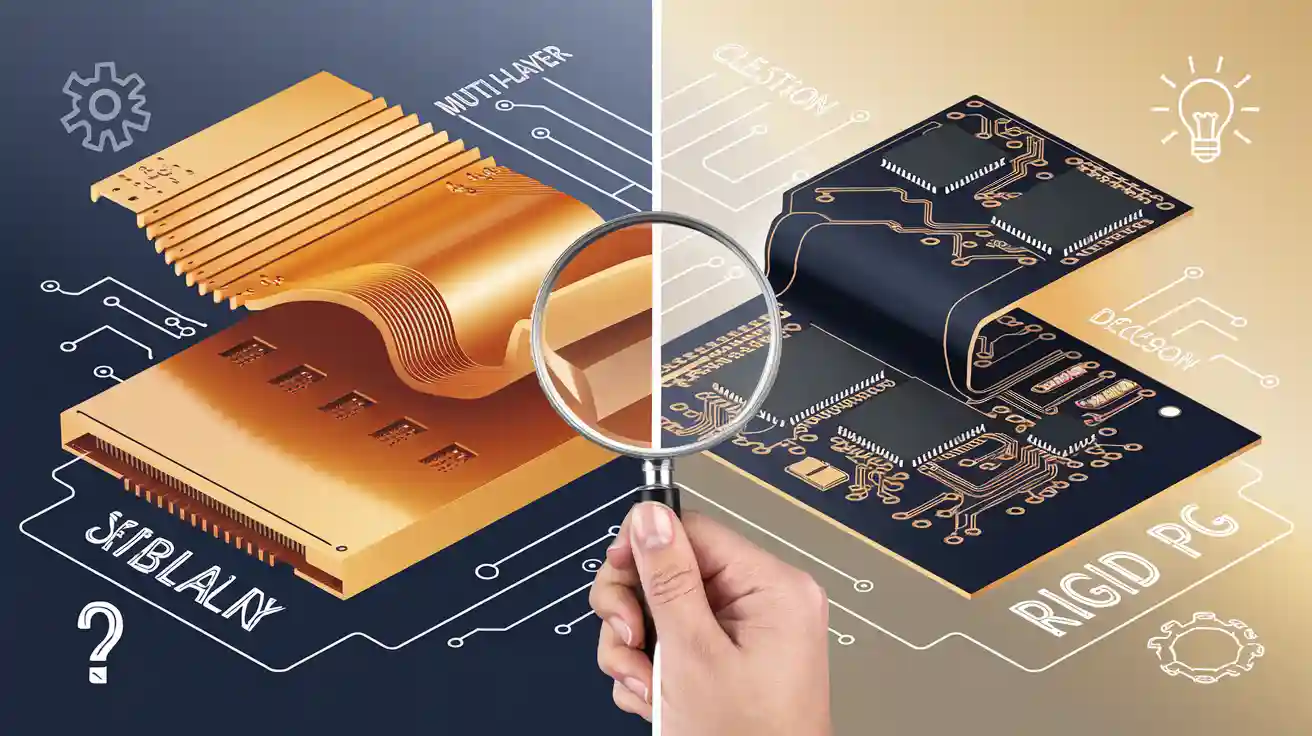

Choosing the best circuit board depends on what your project needs. Engineers pick multi layer FPCs for light and bendy gadgets in wearable tech. Rigid-flex PCBs work well for things that need both stiff and bendy parts, like smart fitness trackers. Each board type has different performance, price, and strength. The material you pick changes the weight and how it handles heat. The table below shows the main differences:

| Criteria | Multi-layer FPCs | Rigid-Flex PCBs |

|---|---|---|

| Performance | Flexible, moderate frequency | Stable, adaptable, durable |

| Cost | Higher | Higher due to complexity |

| Durability | Withstands bending | Combines flexibility, stability |

| Design Flexibility | Thin, curved designs | Integrated rigid/flex sections |

| Application Suitability | Wearables, compact electronics | Dynamic, advanced devices |

Key Takeaways

- Multi layer FPCs are thin and light. They are very flexible. These are good for small, bendy devices. You can use them in wearables and foldable screens.

- Rigid-flex PCBs have stiff and flexible parts. They are strong and last a long time. They give great signal quality. These work well for tough and high-performance projects.

- Multi layer FPCs cost less to make. They are easier to build, especially in small batches. Rigid-flex PCBs cost more money. They are better for heavy use and complex designs.

- Making flexible PCBs needs careful planning. You must think about bend radius and layer alignment. This helps stop damage and keeps them working well for a long time.

- Picking the right PCB depends on your project’s needs. Think about space, flexibility, durability, cost, and complexity. Talking to experts helps you choose the best one.

Multi-layer FPCs Vs Rigid Flex PCBs

Circuit Board Performance

Engineers look at how well circuit boards work. They compare multi layer FPCs and rigid-flex PCBs. Multi layer FPCs are very flexible and light. This makes them good for small devices. Rigid-flex PCBs have better signal quality. They keep signals strong, even after bending many times. These boards control impedance within ±5%. They also block crosstalk up to -50dB. This is because of shielding layers and special routing. Rigid-flex PCBs handle fast signals well. Thick copper and power planes help with this. Their design spreads out stress. This lets them bend over 1,000 times. Both types use strong materials like DuPont polyimide. Rigid-flex PCBs work better in tough places. They resist heat and shaking.

| Performance Metric | Multi Layer FPCs | Rigid-Flex PCBs |

|---|---|---|

| Impedance Control | Moderate, less precise | ±5% accuracy, stable after bends |

| Crosstalk Suppression | Basic | -50dB with shielding |

| Signal Stability | Good for moderate speeds | Excellent for high-speed signals |

| Mechanical Reliability | Good for light use | Superior, 1000+ bend cycles |

| Thermal/Vibration Testing | Limited | -40°C to 125°C, ≥20G vibration |

FPC Quote Cost

Cost is important when picking a PCB. Multi layer FPCs usually cost less to make. This is true for small and medium batches. The material for multi layer FPCs costs about $0.50 per square inch. Rigid-flex PCBs cost $1.50 or more per square inch. Making multi layer FPCs is simpler. The unit price is about $2 for each device. Rigid-flex PCBs need special tools and more steps. Their unit price is $5 to $7. Prototypes also cost less for multi layer FPCs. They are under $300. Rigid-flex PCBs cost $500 to $1,000 for prototypes. When making many boards, rigid-flex PCBs get a bit cheaper. But they still cost more than multi layer FPCs.

| Cost Aspect | Multi Layer FPCs | Rigid-Flex PCBs |

|---|---|---|

| Material Cost (per sq. in) | ~$0.50 | ~$1.50+ |

| Manufacturing Cost | 20-40% less than rigid-flex | Higher, complex process |

| Unit Cost (Low/Med Volume) | ~$2 | $5–$7 |

| Prototype Cost | <$300 | $500–$1,000 |

| Volume Impact | Cost-effective <10,000 units | Scales down, still higher |

Tip: Swiss startups and small companies save money with multi layer FPCs. These are best for wearable and portable gadgets.

PCB Durability

Durability shows how well a board handles bending and stress. Both multi layer FPCs and rigid-flex PCBs use polyimide. This gives them heat resistance and flexibility. Designers pick copper laminates without glue. This lowers stress when bending. Rigid-flex PCBs often have stiffeners under parts. This gives extra support. To stop damage, engineers use a bend radius 10 times the material thickness. Traces go across bend lines, not along them. They are made wider to stop cracks. Vias and parts are kept away from bends. If not, they get extra support. Both types follow IPC rules for strength. They are tested for thousands of bends. Rigid-flex PCBs spread out stress better. This makes them good for things that bend a lot.

- Use polyimide for heat and flexibility.

- Pick copper laminates without glue.

- Keep bend radius at least 10 times thickness.

- Put traces across bend lines.

- Make vias stronger if in bend areas.

- Add stiffeners under parts in rigid-flex PCBs.

- Test for thousands of bends.

Printed Circuit Board Flexibility

Flexibility is a big plus for both board types. Multi layer FPCs are thin and light. They fit curved and small designs. More layers mean a bigger bend radius is needed. For example, a 0.1 mm thick multi layer FPC needs a 1.0 to 1.2 mm bend radius for static use. For moving bends, the radius should be 20 times the thickness. Rigid-flex PCBs mix stiff and flexible parts. They follow the same bend rules. Flexible parts must be designed carefully. This stops damage but limits tight bends. Bigger bend radii make boards last longer. But this can limit where parts and traces go.

| Layer Count | Static Minimum Bend Radius (x thickness) | Dynamic Minimum Bend Radius (x thickness) |

|---|---|---|

| Single Layer | 10 | 100 |

| Double Layer | 10 | 150 |

| Multi Layer | 20 | Not advised |

Note: Multi layer FPCs are best for light, curved designs. Rigid-flex PCBs work for complex shapes with stiff parts.

PCB Board Applications

The right board depends on your project needs. Multi layer FPCs are great for small, light devices. These include smartwatches and fitness bands. They fit in tight spaces and allow creative shapes. Rigid-flex PCBs are used in advanced electronics. These include medical tools, aerospace, and factory controls. They mix stiff and flexible parts. This helps with placing parts and routing traces. Rigid-flex PCBs also handle heat and movement well. This makes them good for places with lots of shaking or motion.

- Multi layer FPCs: Wearables, small electronics, light sensors.

- Rigid-flex PCBs: Medical tools, aerospace, car electronics, factory machines.

Swiss engineers often pick multi layer FPCs for new consumer products. Rigid-flex PCBs are chosen for tough jobs needing strength and high performance.

Multi Layer FPCs

Complex Multi Layer FPCs Structure

A multi layer fpc has many layers of copper circuits. These layers are stacked on top of each other. Polyimide film holds the layers together. This film makes the board bend and resist heat. Cover layers keep the copper safe from water and scratches. Designers can use up to 20 layers in one board. This lets them fit lots of wires in small spaces. The board can be stacked in 3D shapes. It fits into tight or curved spots easily. The board is thin and light. Engineers use it to make small and light devices.

Multi Layer Flex PCBs Strengths

Multi layer fpc boards have many good points. They bend and twist without breaking. This is great for things that move or fold. Their thin build saves space and weight. This helps with portable electronics. Engineers can make cool shapes and layouts. This makes products look better and work better. These boards can hold complex circuits. This is useful for advanced devices.

Note: Multi layer fpc boards need fewer connectors and cables. This means faster assembly and fewer failures.

Multi-layer Flexible Circuits Weaknesses

Multi layer fpc boards also have some problems. They cost more than single-layer or rigid boards. Making them needs careful work and perfect alignment. This can take more time to produce. The thin material is not good for heavy parts or strong hits. Designers must not use sharp bends. They need to keep the bend radius big to stop damage. If the board breaks, it is hard to fix.

Best FPCs Uses

Devices that bend a lot or need to be very thin use multi layer fpc boards. Foldable screens and flexible LCDs use these boards. They bend well and save space. Portable signs and foldable ads also use these circuits. They are light and bend many times. Multi layer fpc boards are best for products with special shapes and low weight. Wearables and new portable electronics use them a lot.

Rigid-Flex PCBs

Rigid-flex PCBs Structure

Rigid-flex PCBs have stiff and bendy parts in one board. The stiff parts use FR-4. FR-4 is strong and keeps parts safe from heat. The bendy parts use polyimide. Polyimide bends easily and lasts a long time. Designers join the stiff and bendy parts inside the board. This means you do not need big connectors. It saves space and makes small devices possible. Smartwatches use this design to save up to 40% space. Using the right materials stops the layers from coming apart. This is important when temperatures change, like in cars.

- Stiff parts: FR-4 gives strength and heat protection

- Bendy parts: Polyimide lets the board bend and stay strong

- Inside connections: No need for big connectors outside

- Space saved: Up to 40% in small gadgets

Soft and Hard PCBs Strengths

Rigid-flex PCBs are strong and work well with electricity. The table below shows how hard and soft PCB parts are different:

| PCB Type | Mechanical Stability | Electrical Performance |

|---|---|---|

| Hard PCBs | Very strong, keeps shape, handles heat well | Some changes in signals, not best for radio waves |

| Soft PCBs | Bends more, not as strong as hard PCBs | Great for fast signals, better for high frequencies |

Hard parts hold parts in place. Soft parts let the board bend and fold. This helps in devices that move or change shape.

Semi-flex PCBs Weaknesses

Semi-flex PCBs can be used in many ways but have some problems. The spot where stiff and bendy parts meet can get weak. If not made right, these spots can crack or split. Heavy parts should not go on bendy areas. This can make the board break. You must keep the bend radius big enough. If not, the board can fail. Making semi-flex boards costs more because they are harder to build.

Note: Good design and picking the right materials help stop these problems and make the board last longer.

Best Rigid-flex PCBs Uses

Rigid-flex PCBs are used in many fields that need small, strong, and good boards.

- Medical tools: Used in implants and test devices where space is tight and the board must work well.

- Aerospace: Used in drones and planes where saving weight and being tough is important.

- Consumer electronics: Needed in smartwatches, folding phones, and wireless earbuds that bend and are small.

Designers must make sure the change between stiff and bendy parts is smooth. They also need to keep signals steady for things like 5G phones. Good polyimide and FR-4 make the boards last longer, especially in medical and aerospace jobs.

Diffenrences Decision Factors

Space

Space is important in all electronics. Multi layer fpc boards are picked for thin and light gadgets. These boards save space by stacking layers close together. Designers use them in wearables and small devices. Rigid-flex PCBs also help save room. They mix stiff and bendy parts, so engineers can put parts in tight places. This design means fewer connectors and cables are needed. Both types make devices smaller, but multi layer fpc boards are the thinnest.

| PCB Type | Space Efficiency | Typical Use Case |

|---|---|---|

| Multi Layer FPC | Very high | Smartwatches, sensors |

| Rigid-Flex PCB | High | Medical devices, drones |

Tip: If your project has little space, flexible circuits work well.

Flexibility

Flexibility shows how well a board fits in things that move. Multi layer fpc boards bend and twist without breaking. They are best for things that fold or bend a lot, like foldable screens. Rigid-flex PCBs have both stiff and bendy parts. This lets them bend in some spots and stay strong in others. Designers use rigid-flex PCBs when they need both bending and support. Rigid PCBs do not bend and are only for things that do not move.

- Multi layer fpc: Great for projects that need lots of bending.

- Rigid-flex PCB: Good for designs needing both bending and strong parts.

Note: Flexible PCBs are good for things that move. Rigid-flex PCBs give both bending and support in one board.

Reliability

Reliability means how long a board lasts and works well. Multi layer fpc boards handle light bends and heat. They can take some shaking, but heavy parts or sharp bends can hurt them. Rigid-flex PCBs are better for tough jobs. They spread out stress between stiff and bendy parts. This helps them last through many bends and hard use. Engineers use rigid-flex PCBs in planes and hospitals where boards cannot fail.

| PCB Type | Reliability Level | Typical Stress Resistance |

|---|---|---|

| Multi Layer FPC | Good | Light bending, moderate heat |

| Rigid-Flex PCB | Excellent | High vibration, repeated bends |

Cost

Cost matters for every project. Multi layer fpc boards are cheaper to make, especially for small batches. Their materials cost less, and making them is easier. Rigid-flex PCBs cost more because they need special tools and more steps. The price goes up if you add more layers or make it complex. For big orders, rigid-flex PCBs get a bit cheaper, but they still cost more than multi layer fpc boards.

- Multi layer fpc: Cheaper materials and easier to make.

- Rigid-flex PCB: Costs more at first, but can save money by using fewer connectors.

Tip: New companies often pick multi layer fpc boards to save money.

Complexity

Complexity means how hard it is to design and build the board. Multi layer fpc boards let you make cool shapes, but you must plan carefully. Designers need to line up layers just right and avoid sharp bends. Rigid-flex PCBs are even harder to make. Engineers must plan where stiff and bendy parts meet. They also test for strong signals and strength. Making rigid-flex PCBs takes longer and needs more skill.

| PCB Type | Design Complexity | Production Difficulty |

|---|---|---|

| Multi Layer FPC | Moderate | Needs precise alignment |

| Rigid-Flex PCB | High | Requires advanced skills |

Projects with simple shapes and few layers are good for multi layer fpc boards. Harder devices with mixed needs use rigid-flex PCBs.

Real-World Examples

Multi Layer FPC Projects

Engineers pick multi layer fpc boards for thin and light products. These boards work well when space is tight and weight is important. Here are some examples:

- Wearable Devices: Fitness trackers and smartwatches use these boards. The boards bend to fit around your wrist. They also fit inside small cases. This keeps the device light and easy to wear.

- Foldable Phones and Tablets: Flexible screens need circuits that can bend a lot. Multi layer fpc boards let the device fold without breaking wires.

- Hearing Aids: These small medical devices need thin and bendy circuits. The boards fit inside the ear and move with you every day.

- Portable Medical Sensors: Engineers use these boards in health monitors that stick to your skin. The circuits bend with your body and keep working well.

Note: Multi layer fpc boards help designers make new shapes and lighter gadgets. They also use fewer connectors, so there is less chance of something breaking.

Rigid-Flex PCB Projects

Rigid-flex PCBs are best for projects needing strong and bendy parts. These boards handle stress and keep signals steady. Here are some real-world examples:

- Medical Devices: Surgical tools and imaging machines use rigid-flex PCBs. The boards fit in small spaces and survive lots of cleaning and movement.

- Aerospace Systems: Satellites and drones need circuits that handle shaking and heat changes. Rigid-flex PCBs give both strength and flexibility.

- Automotive Electronics: Modern cars use these boards in dashboards and control units. The boards connect moving parts and keep working for a long time.

- Industrial Robots: Rigid-flex PCBs help robots move and bend while keeping electronics safe.

| Project Type | Best PCB Choice | Key Benefit |

|---|---|---|

| Fitness Tracker | Multi layer fpc | Thin, flexible, lightweight |

| Surgical Tool | Rigid-flex PCB | Durable, reliable |

| Foldable Phone | Multi layer fpc | Bends without breaking |

| Drone Controller | Rigid-flex PCB | Handles vibration, heat |

Tip: If your project needs both bending and strength, rigid-flex PCBs are a good choice.

Engineers have to think about space, how much the board can bend, how long it will last, how much it costs, and how hard it is to make. Rigid-flex PCBs are good for tough projects that need to be strong and bendy. Multi layer FPCs work best in small and light gadgets. What the board is made of and how much money you have are important. Teams should talk to PCB experts before picking a board. Getting help from pros makes sure you get the right board for your project.

2025-08-19

2025-08-19

BEST

BEST

.png)

.png)

.png)

.png)

.png)