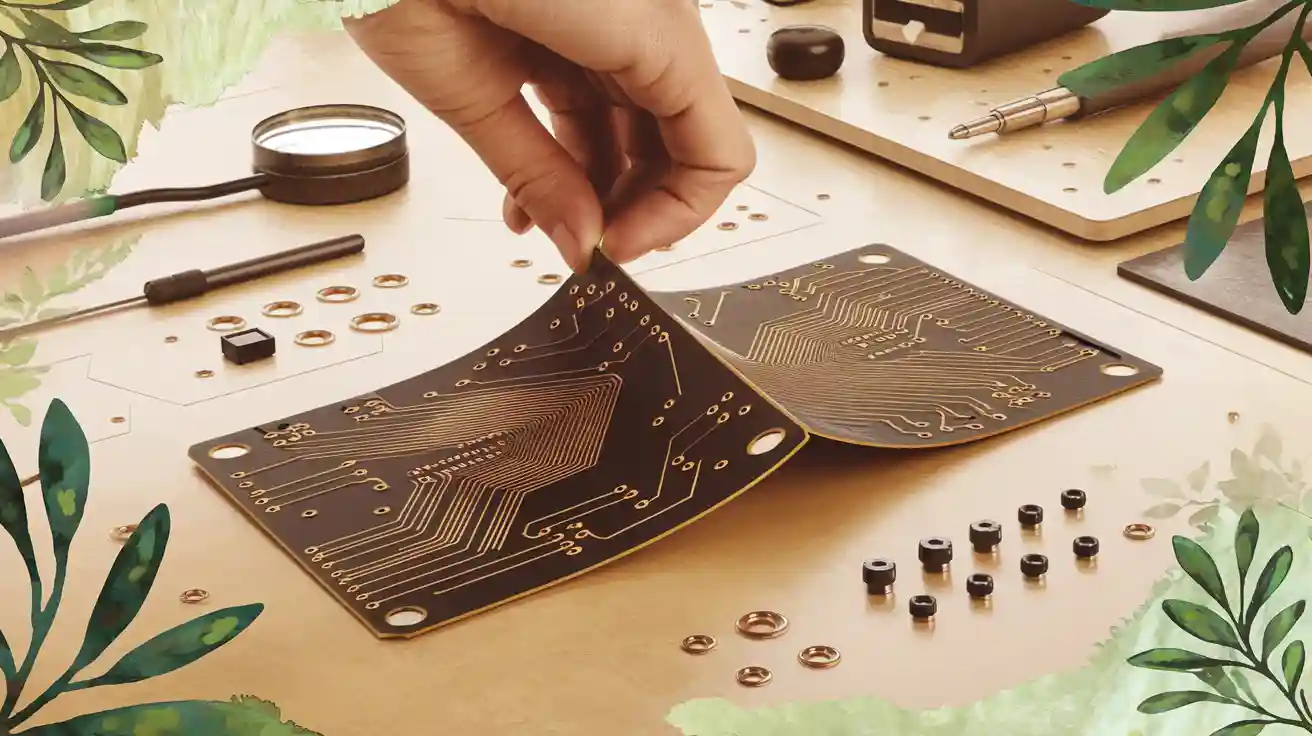

Loose Leaf Flex PCB: Benefits and Drawbacks

Loose leaf flex PCBs are flexible, lightweight, and save space. These traits are perfect for small, modern designs. They work well in devices that move or need tight spaces. But, they also have some problems. Making them needs great care, which costs more money. Plus, their thin design makes them easier to damage when handled. Even with these issues, loose leaf flex PCBs are important for advanced uses where regular rigid PCBs don’t work.

Key Takeaways

- Loose leaf flex PCBs are bendable and light, perfect for small gadgets.

- They can fold and twist, helping create cool designs for wearables and tiny devices.

- Even though they are useful, they cost more to make and need gentle handling to prevent harm.

- Think about your project needs. These PCBs work well in moving setups but might not handle heat well.

Understanding Loose Leaf Flex PCBs

Definition and Structure

A loose leaf flex PCB is a special circuit board. It can bend and twist without breaking. Unlike stiff boards, these use thin, bendable materials like polyimide or polyester. This makes them fit into small spaces or moving devices.

The board has several layers. The bottom layer is a flexible base that holds everything. On top, copper lines create the circuit paths. A coverlay or solder mask protects the circuits from damage and the environment. These layers make the board strong but flexible.

- Tip: These PCBs are great for tight spaces or moving parts.

Key Differences from Rigid PCBs

Loose leaf flex PCBs are very different from rigid ones. The biggest difference is flexibility. Rigid PCBs are hard and made of fiberglass. Flex PCBs use soft, bendable materials. This lets them fold or fit odd shapes.

They are also lighter than rigid PCBs. This makes them perfect for portable gadgets. They work well in places where rigid boards might break under stress. But making them is harder and needs special tools.

Flex PCBs can handle bending many times. However, they are easier to damage when handled. Rigid PCBs are tougher but can’t bend or fit into small spaces.

- Note: Pick the type based on your needs. If you need flexibility and lightness, choose loose leaf flex PCBs.

Advantages of Loose Leaf Flex PCBs

Flexibility for Compact Designs

Loose leaf flex PCBs are great for tight spaces. They can bend, fold, and twist to fit small or odd shapes. Unlike rigid PCBs, they don’t need flat, open areas. These flexible boards work well in wearables, foldable gadgets, and small devices.

Their flexibility also reduces the need for extra connectors or cables. By curving the PCB, parts can connect directly. This makes the design simpler and more reliable. Fewer connectors mean fewer chances for something to break.

- Tip: Use loose leaf flex PCBs for small, efficient designs.

Lightweight for Portable Devices

Portable electronics need to be light. Loose leaf flex PCBs weigh much less than rigid ones. Their thin materials help make devices like phones, tablets, and drones lighter.

Being lightweight also saves energy. In battery-powered devices, lighter PCBs use less power. This helps batteries last longer. Whether it’s a fitness tracker or medical gadget, these PCBs keep devices light and functional.

- Note: Loose leaf flex PCBs improve portability without losing performance.

Durability in Dynamic Environments

Moving parts need strong components. Loose leaf flex PCBs handle bending and stress without breaking. They’re perfect for robots, cars, and wearables that move a lot.

These PCBs also resist shocks and vibrations better than rigid boards. For example, in cars, they stay reliable despite constant shaking. In wearables, they hold up to frequent motion without damage.

- Callout: For devices in tough or moving conditions, choose loose leaf flex PCBs.

High-Density Circuit Integration

Loose leaf flex PCBs are great for fitting many parts in small spaces. Their special design lets you add more components without losing performance. This makes them perfect for modern gadgets where space is limited.

These PCBs can have multiple layers, allowing more connections in tight areas. Unlike rigid PCBs, they don’t need extra room for connectors or wires. This helps save space and makes devices lighter.

- Tip: Loose leaf flex PCBs improve signals by keeping parts close together.

They also support tricky circuit designs. You can place traces in 3D shapes, making creative layouts possible. For example, in wearables, these PCBs can bend or curve to match the product’s shape while keeping circuits packed tightly.

High-density designs make devices more reliable. Fewer connectors and cables mean fewer chances for problems. This is especially useful for industries like aerospace and medical tools, where reliability matters most.

- Callout: Need small, powerful circuits? Loose leaf flex PCBs combine smart design with great performance.

Disadvantages of Loose Leaf Flex PCBs

Higher Production Costs

Loose leaf flex PCBs cost more than rigid PCBs. This happens because they need special materials and methods to make them. Flexible bases like polyimide cost more than fiberglass used in rigid boards. Making these PCBs also needs careful work and advanced machines, which adds to the price.

Prototyping can also be expensive. These PCBs need custom designs for specific uses. Creating these designs takes extra time and money. For small projects, this cost might be a big problem.

- Note: If your budget is tight, think about whether the flexibility and lightweight design are worth the extra cost.

Fragility During Handling

Loose leaf flex PCBs are flexible but easier to damage. Their thin and light design makes them delicate during assembly or installation. Bending too much, rough handling, or too much pressure can cause cracks or tears.

You must handle these PCBs carefully with the right tools. For example, bending them too far can ruin them permanently. This fragility can lead to more defects, especially when making many boards at once.

- Tip: Teach your team how to handle these PCBs properly to avoid damage and waste.

Complex Assembly Requirements

Putting together loose leaf flex PCBs is harder than rigid ones. Their flexible design makes it tricky to hold them steady during soldering or adding parts. You might need special tools or glue to keep them in place.

These PCBs also need careful planning. You must think about how they bend and where parts go to avoid stress. This makes assembly take longer and costs more for labor.

- Callout: Hiring skilled workers and using better tools can make assembly faster and easier.

Limited Heat Resistance

Loose leaf flex PCBs are useful but don’t handle heat well. Materials like polyimide or polyester make them flexible and light. However, these materials resist heat less than fiberglass in rigid PCBs. This makes them unsuitable for very hot environments.

Too much heat can damage the flexible base. It might bend or weaken, causing circuits to fail. For example, in devices like power tools or machines that get hot, these PCBs may stop working over time.

- Tip: Always check if your PCB materials can handle your device's heat.

Soldering is another issue. The heat from soldering can harm the flexible layers. To avoid this, you might need cooler soldering methods or special tools. This makes production harder and more expensive.

Also, these PCBs don’t work well in places with changing temperatures. For example, cars or planes face extreme heat and cold. You might need extra protective layers, but this adds weight and reduces flexibility.

- Callout: For high-heat or changing temperatures, rigid-flex PCBs might work better.

To make these PCBs last longer, keep them cool. Use heat sinks, fans, or other cooling methods to protect them. Planning for heat control during design can prevent problems later.

- Note: Loose leaf flex PCBs are great for small designs but not for hot conditions.

Applications of Loose Leaf Flex PCBs

Medical Devices

Loose leaf flex PCBs are important in modern medical tools. Their light and bendable design helps make small devices. These fit into tight spaces or wearable gadgets. For example, they are used in heart monitors, insulin pumps, and imaging machines. They can bend to fit unique shapes, making them great for worn or inserted devices.

These PCBs allow many circuits in small spaces. This helps connect sensors and processors without making devices bulky. They are strong and work well even when patients move or during transport. But, you need to think about heat issues for tools that get very hot, like surgical equipment.

- Tip: Loose leaf flex PCBs make medical devices smaller, smarter, and easier to carry.

Consumer Electronics

Loose leaf flex PCBs are key for consumer gadgets. Their flexibility helps create foldable phones, wearables, and tiny cameras. These PCBs remove the need for big connectors, making devices slim and efficient. Their lightweight design makes products like smartwatches and earbuds easier to carry.

They also allow more features in small spaces. This improves performance without making devices bigger. For example, they help create advanced touchscreens and clear displays in phones. Their ability to bend and move makes them durable for daily use.

- Callout: Loose leaf flex PCBs help build stylish and useful electronics.

Automotive Systems

Cars use loose leaf flex PCBs for many systems. Their flexibility fits circuits into small areas like dashboards, sensors, and lights. These PCBs handle shaking and bumps better than stiff boards, keeping them reliable in vehicles.

Their lightweight design helps cars save fuel by lowering weight. In electric cars, they improve battery use and energy efficiency. They also support features like GPS, entertainment systems, and driver-assist tools.

But, they don’t handle heat well. Cars face extreme temperatures, so extra protection may be needed to make them last longer.

- Note: Loose leaf flex PCBs are great for modern cars, offering flexibility, strength, and space-saving benefits.

Aerospace and Defense

Loose leaf flex PCBs are very important in aerospace and defense. They work well in places needing reliability, less weight, and small designs.

Why Choose Loose Leaf Flex PCBs?

- Lightweight Design: Planes and spacecraft need lighter parts to save fuel. Loose leaf flex PCBs are thin and light, helping with this goal.

- Compact and Flexible: These PCBs fit small spaces and odd shapes. This is useful for advanced systems like avionics and missile controls.

- Durability Under Stress: Aerospace and defense tools face tough conditions like shocks and heat. Loose leaf flex PCBs handle these better than stiff boards.

- Tip: Pick loose leaf flex PCBs when saving weight and space matters most.

Problems in Aerospace and Defense Use

Even with benefits, these PCBs have some problems:

- Strict Manufacturing Needs: Aerospace and defense need perfect parts. Making loose leaf flex PCBs for them costs more due to high standards.

- Weak Heat Resistance: Jet engines and space heat can harm flexible materials. Extra layers or cooling systems might be needed, making designs harder.

Common Uses

- Avionics: These PCBs help with navigation, communication, and control systems.

- Defense Tools: Drones, radars, and missile electronics use these lightweight and strong PCBs.

- Spacecraft: Satellites and rockets use them because they fit tight spaces and survive harsh conditions.

Callout: Loose leaf flex PCBs are key for aerospace and defense. They offer flexibility and strength for advanced technology.

Loose leaf flex PCBs are bendable, light, and fit many circuits. These traits make them great for small and moving devices. But, they cost more to make, break easily, and need careful assembly. They work best in fields like medicine, gadgets, and space tech. Think about your project’s needs to decide if these PCBs are the right pick.

FAQ

1. What makes loose leaf flex PCBs different from rigid-flex PCBs?

Loose leaf flex PCBs can bend completely, unlike rigid-flex PCBs. Rigid-flex PCBs mix stiff and flexible parts for added strength. Loose leaf flex PCBs are better for designs needing full flexibility. Rigid-flex PCBs are stronger and work well in tough conditions.

- Tip: Choose rigid-flex PCBs for heat or heavy stress environments.

2. Can loose leaf flex PCBs handle high-frequency signals?

Yes, they can manage high-frequency signals effectively. Their small design keeps components close, reducing signal loss. Adding shielding helps prevent interference in these applications.

- Note: Flex PCBs lower parasitic capacitance, improving high-frequency circuits.

3. How do you protect loose leaf flex PCBs from heat damage?

Use materials like polyimide that resist heat. Add cooling tools like fans or heat sinks. Avoid exposing them to high temperatures for long periods.

- Callout: Good heat control makes flex PCBs last longer.

4. Are loose leaf flex PCBs suitable for mass production?

Yes, but they need special tools and trained workers. Production costs and time are higher than for rigid PCBs. Careful planning can help reduce these challenges.

- Tip: Simplify your design to save time and money.

5. What industries benefit most from loose leaf flex PCBs?

Many industries use these PCBs, including medical, electronics, cars, and aerospace. They are great for small, light, and strong designs.

| Industry | Key Benefit |

|---|---|

| Medical Devices | Small and wearable designs |

| Consumer Electronics | Lightweight and portable |

| Automotive Systems | Handles shaking and bumps |

| Aerospace | Light and dependable |

Note: Check your project needs before choosing flex PCBs.

2025-05-23

2025-05-23

BEST

BEST

.png)

.png)

.png)

.png)

.png)