A led flex pcb is a special circuit board. It is made from materials that can bend. It connects and powers LEDs. It does this by moving electricity through thin, bendy paths. Flexible designs help engineers put lights on curved surfaces. They also use them in wearables and inside cars. The global market for flexible PCBs has grown fast. It is now worth billions of dollars. More industries want energy-saving and creative lighting. People interested in lighting technology can learn a lot. They can see how a led flex pcb helps lights last longer and work better.

Key Takeaways

- LED flex PCBs are bendable boards. They power LEDs in small or curved spaces. Regular boards cannot fit in these places.

- These boards use special materials like polyimide and rolled annealed copper. These materials help the boards handle heat. They also let the boards bend many times without breaking.

- Flexible PCBs help designers make new lighting shapes. They are used in wearables, cars, homes, and digital signs. These lights are bright and save energy.

- Good heat management in LED flex PCBs keeps LEDs cool. This makes the lights last longer and work better.

- Flexible PCBs are strong and let designers be creative. They let lights fit in small, moving, or odd places. They also save energy and cut down on waste.

LED Flex PCB Basics

What Is an LED Flex PCB

A led flex pcb is a printed circuit board that can bend and twist. It does not break when it moves. This board uses thin, bendy materials instead of hard ones. Engineers use these boards to power LEDs in tight spaces. Regular boards cannot fit in these places. These boards work well in things that move or change shape. Some examples are wearable gadgets, curved screens, and car interiors. Flexible printed circuits help designers put lights around corners or in small spots. This makes them very useful for new lighting ideas.

Key Materials and Structure

Flexible printed circuit boards have many layers and special materials. The main layer is polyimide film. Polyimide can handle high heat and lots of bending. Some boards use polyester, but polyimide is better with heat. The copper foil is the part that carries electricity. Engineers pick rolled annealed copper because it bends without breaking. Glue like epoxy or acrylic sticks the copper to the base. A coverlay made from polyimide or polyester keeps the copper safe from harm and water.

Some led flex pcbs use aluminum as the bottom layer. Aluminum helps take heat away from the LEDs. This keeps them cool and working longer. Some boards have a ceramic polymer layer for more heat and stress protection. The layers in a flexible printed circuit board are:

- Substrate layer (polyimide or polyester)

- Copper conductive layer (single or double-sided)

- Adhesive layer

- Coverlay film for protection

- Solder mask and silkscreen for markings

Note: The materials and thickness of each layer change how much the board bends and how well it handles heat.

Flexible printed circuits can be single-layer or double-layer. Single-layer boards are thinner and bend more. Double-layer boards have copper on both sides. They are stronger and spread heat better, but they do not bend as much.

Flexibility vs. Rigid PCBs

Flexible printed circuit boards are different from rigid boards in many ways. Rigid PCBs use FR-4 epoxy laminate. This makes them stiff and strong, but they cannot bend. Flexible printed circuits use thin polyimide films. These let them bend, twist, and fold. This means engineers can use them where rigid boards would break or not fit.

| Feature | Rigid PCBs | Flex PCBs |

|---|---|---|

| Substrate Material | FR-4 epoxy, ceramic-filled laminates | Polyimide film, polyester, PTFE |

| Flexibility | Low (cannot bend) | High (can bend and twist) |

| Max Temp (°C) | 130–260 | Up to 400 |

| Thickness | Thick, stable | Thin, lightweight |

| Use Cases | Computers, TVs, industrial machines | Wearables, curved lights, automotive LEDs |

Rigid boards are best for things that do not move and need to be strong. Flexible printed circuit boards are great for products that move, bend, or need to fit odd shapes. Some designs use both types together. These are called rigid-flex PCBs. They give the good parts of both kinds.

Flexible printed circuits have changed how engineers make lighting. Now, they can put LEDs in places they could not before. This helps people come up with new and smart lighting ideas.

How LED Flex PCBs Work

Electrical Pathways

Electrical pathways in flexible PCBs send power and signals to each LED. These pathways are thin copper lines that can bend with the board. Engineers make these lines strong so they do not break when bent. The copper is rolled and annealed, which makes it tough and bendy. This helps the board last through many bends.

Flexible PCBs are not the same as rigid PCBs. The table below shows how they are different:

| Aspect | LED Flex PCBs (Flexible) | Traditional Rigid PCBs |

|---|---|---|

| Substrate Material | Polyimide, flexible, thermal resistance up to 400°C | FR-4, glass-reinforced epoxy laminate, rigid |

| Copper Traces | Rolled annealed copper, thinner (0.5-1 oz/ft²), designed to endure bending and flexing | Thicker copper (1-2 oz/ft²), rigid and stable |

| Bend Radius | Very small (as low as 0.1 mm), supports dynamic flexing | Inflexible, no bending capability |

| Signal Integrity | Requires careful impedance control to maintain signal quality during bending | Stable dielectric properties support high-speed signals without flex-induced degradation |

| Mechanical Stress | Designed to withstand repeated flex cycles (hundreds of thousands) | Not designed for flexing, prone to damage if bent |

| Thermal Conductivity | Lower (~0.2 W/m·K), less efficient heat dissipation | Higher (~0.3 W/m·K), better thermal management |

| Application Impact | Enables compact, foldable LED designs with maintained electrical performance | Provides stable mounting and signal integrity for fixed LED assemblies |

Flexible PCBs let designers put lights in small or curved places. The copper lines keep working even when the board bends. This makes flexible PCBs great for wearables, car parts, and new lighting ideas.

LED Integration

Engineers put LEDs right onto the surface of flexible PCBs. They use surface-mount technology to stick each LED to copper pads. This keeps LEDs close to the board, saving space and helping heat move away. Flexible PCBs can hold lots of LEDs in a small spot, making lights bright and even.

Designers can put LEDs in lines, curves, or special shapes. The board bends, so LEDs can go around corners or on bumpy surfaces. This lets people make creative lighting designs. For example, car makers use flexible PCBs for LED strips in dashboards and doors. Wearables use them for thin, glowing bands or screens.

Flexible PCBs work with many types of LEDs, like single-color, RGB, or addressable LEDs. Engineers can control each LED by itself, making cool lighting effects. The board’s design gives each LED the right power and keeps them connected, even when bent or twisted.

Heat Dissipation

LEDs get hot when they are on. Too much heat can hurt the LEDs and make them not last as long. Flexible PCBs use different ways to get rid of heat and keep LEDs cool.

| Technique | Description |

|---|---|

| Thermal Vias | Small holes through PCB layers that transfer heat vertically to outer layers for dissipation. |

| Aluminum Heat Sinks | Attached to high-temperature areas to increase surface area for heat transfer. |

| Copper Planes | Copper layers strategically placed to spread heat away from hotspots. |

| Coverlay Lamination | Polymer layer with thermal conductivity acting as a heat sink on the PCB surface. |

| Proper Adhesive | Use of thermally conductive adhesives to improve heat transfer between layers and components. |

| PCB Layout Optimization | Strategic placement of components and copper planes to enhance airflow and heat distribution. |

| Material Selection | Choosing materials with high thermal conductivity to facilitate heat dissipation. |

| Thinner Core/Coverlay | Reducing thickness to lower thermal resistance and improve heat conduction. |

Designers use these ways to help flexible PCBs lose heat:

- Copper pour designs help heat move away fast.

- Thermal vias let heat move up and down through layers.

- Aluminum and special materials help heat move out.

- Cooling systems keep LEDs working well for a long time.

To make heat management better, engineers do these things:

- Use adhesives that can handle high heat, up to 220°C.

- Make the board bigger to help heat escape.

- Use thin core and coverlay materials for better heat flow.

- Add aluminum heat sinks to move heat away.

- Put copper planes in the right spots to spread heat.

- Use sticky adhesives to attach boards to metal cases.

- Stay under the max temperature for all materials.

- Add heat pipes or spreaders made of aluminum or graphite.

- Use thermal via arrays that still let the board bend.

- Make cases that let air move or heat escape.

- Use computer tools to find hot spots and fix them.

- Keep heat sources and sinks close, and don’t put hot parts together.

- Make copper lines wide and spaced out to lower heat.

- Balance the number of layers for good heat flow and bending.

- Use shielding materials like Kevlar or titanium for safety.

- Use solid or cross-hatched copper or silver layers for EMI shielding.

Tip: Good heat control helps LEDs last longer and shine brighter. Flexible PCBs with good heat loss can power bright lights in small spaces without getting too hot.

A led flex pcb uses smart copper lines, careful LED placement, and good heat control. These things help flexible PCBs power modern lights in ways rigid boards cannot.

Why Use LED Flex PCBs

Flexibility and Durability

Flexible pcbs are special because they can bend and twist. They do not break when you fold them. This makes them great for things that move or fit in small spaces. Flexible pcbs can bend many times and still work. This is important for wearable technology and devices that check things all the time. In cars and robots, flexible pcbs keep working even with shaking or bumps.

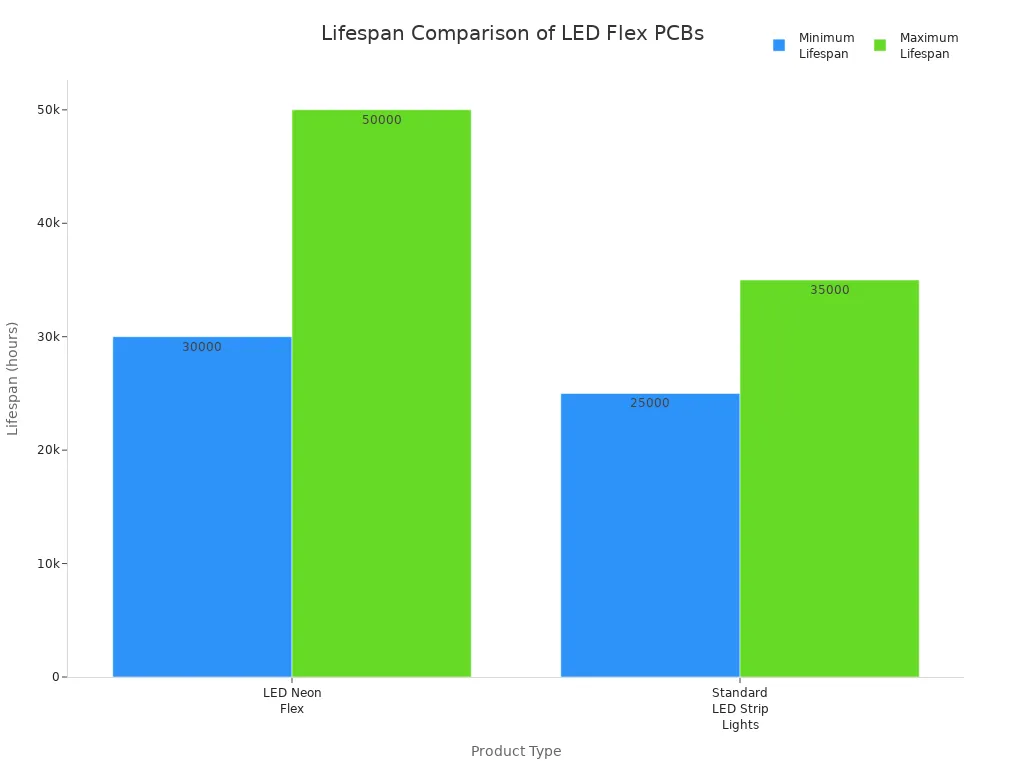

The table below shows how long different flexible lights last and how strong they are:

| Feature | LED Neon Flex | Standard LED Strip Lights |

|---|---|---|

| Lifespan (hours) | 30,000 to 50,000 | 25,000 to 35,000 |

| Design | Enclosed silicone/polyurethane body | Exposed or semi-exposed design |

| Environmental Protection | High (IP65 to IP68, UV resistant) | Limited, mostly indoor use |

| Durability Factors | Resistant to dust, moisture, physical damage | Vulnerable to heat, humidity, adhesive weakening |

| Suitable Environments | Outdoor, harsh climates, permanent installations | Indoor, protected outdoor spots, short-term use |

| Maintenance Needs | Low due to robust protection | Higher due to potential LED fading and damage |

Flexible pcbs use rolled annealed copper and polyimide coverlay. These materials stop cracks and keep circuits safe from heat and water. This helps flexible pcbs last longer and need less fixing, even in hard places.

Design Freedom

Flexible pcbs let designers make many shapes. They can fold them into rectangles, cubes, or other forms. This helps engineers put lights in small or odd spaces. Flexible pcbs are used in led embedded clothes and smart towels for wearables. Designers also use them in things that need to check health or sports in real time.

- Flexible pcbs can bend into many shapes for cool lights.

- They work well in wearables, helmets, and smart fabrics.

- Flexible pcbs do not break from shaking or bumps, which helps moving things.

Flexible pcbs help engineers make lights for new products. Wearable technology and the Internet of Things make flexible pcbs even more useful.

Common Applications

Flexible pcbs are used in many lights we see every day. In stores, they light up signs and displays. In cars, flexible pcbs control dashboard lights, headlights, and brake lights. At home, they are in smart bulbs and led embedded clothes.

- Store signs and lights use flexible pcbs for bright light.

- Car lights use flexible pcbs for dashboards and headlights.

- Home lights use flexible pcbs in smart bulbs and led clothes.

Flexible pcbs often have aluminum bases to help get rid of heat. This keeps LEDs cool and helps them last longer. Flexible pcbs also make products smaller and easier to move. Because they bend and fit in special spaces, they are the best choice for new lighting ideas.

Advanced Lighting Solutions

Innovative Designs

Engineers use flexible LED PCBs to make lights fit many shapes. These designs change how we use light every day. Flexible PCBs let lights bend around car parts and building walls. They also fit inside wearable devices. Some cool designs are:

- Car lights that fit dashboards, doors, and headlights for better looks and saving energy.

- Wearable tech like smartwatches and fitness bands where flexible lights add comfort and last longer.

- Building lights for bridges and monuments that can show moving colors.

- Digital signs that bend and twist for fun ads.

- Big curved video screens at shows and sports events.

- Home and office lights like cove lights and accent panels.

- Art displays that use light for fun and hands-on experiences.

Flexible LED PCBs use new materials like graphene-based substrates and ceramic-polymer mixes. These help the boards bend more, handle heat better, and last longer. Chip-on-Board technology lets more LEDs fit in small spaces. This makes lights brighter and use less energy.

Performance Benefits

Flexible LED PCBs work better than old lights. They use less power, so you save money and energy. Most of the power turns into light, not heat. This keeps them cool and helps them last longer. Many flexible LED modules work for up to 50,000 hours. This means you do not have to change them often.

The table below shows the main performance benefits:

| Performance Benefit | Description |

|---|---|

| Energy Efficiency | Flexible LED PCBs can save up to 80% energy compared to old bulbs, cutting costs and pollution. |

| Extended Lifespan | LEDs often last over 50,000 hours, reducing the need for new lights and repairs. |

| Thermal Management | Metal-core designs help spread heat, keeping LEDs safe and boosting performance. |

| Brightness and Color | Flexible PCBs support many colors and brightness levels for creative lighting. |

| Compact Form | The flexible design fits many uses and spreads light evenly. |

Flexible LED PCBs are also good for the planet. They use less material and weigh less. They last longer, so there is less trash. Many companies use green ways to make them and use parts that can be recycled. This makes flexible lighting a smart choice for both good performance and helping the environment.

LED flex PCBs are made with bendy materials like polyimide. They can bend and fold to fit in tight spots. This makes them great for smart lights and things you can wear.

- These boards help control heat better and make products more reliable. They let people design lights in ways that stiff boards cannot.

- Because they are thin and tough, products last longer and use less power.

As lighting gets better, LED flex PCBs will help create new ideas for homes, cars, and smart gadgets.

FAQ

What makes LED flex PCBs different from regular PCBs?

LED flex PCBs use bendable materials like polyimide. Regular PCBs use stiff materials. Flex PCBs can twist and fit into tight spaces. Rigid PCBs cannot bend. Flex PCBs work well in wearables, cars, and curved lights.

Can LED flex PCBs handle high temperatures?

Yes. Polyimide and special adhesives help LED flex PCBs resist heat. Many flex PCBs work at temperatures up to 400°C. This keeps LEDs safe and working longer.

Where do people use LED flex PCBs most often?

People use LED flex PCBs in car lights, wearable devices, smart home lights, and digital signs. These boards fit in places where rigid PCBs cannot go.

How do LED flex PCBs help with energy savings?

LED flex PCBs use less power because they support efficient LEDs. Most of the energy turns into light, not heat. This saves money and helps the environment.

2025-08-07

2025-08-07

BEST

BEST

.png)

.png)

.png)

.png)

.png)