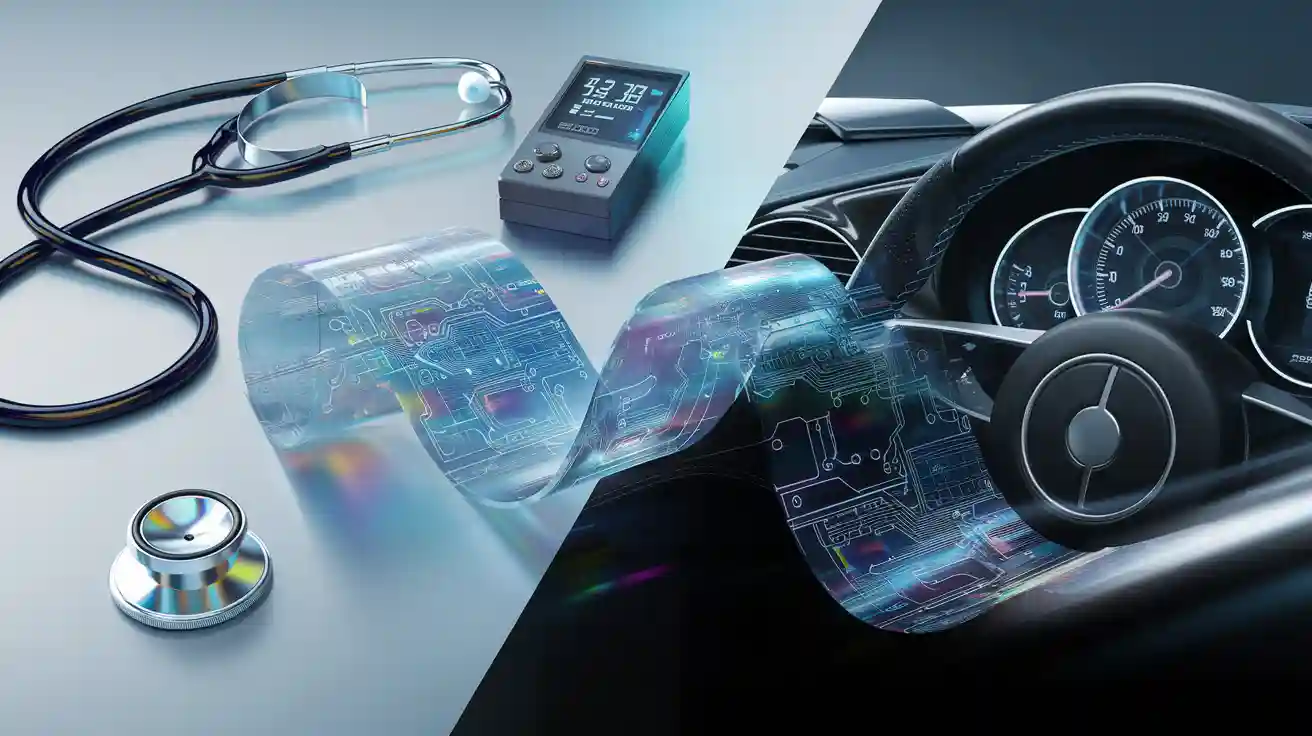

The fpc system brings a new era of design possibilities to both medical and automotive fields. Engineers now rely on advanced substrate materials such as polyimide and liquid crystal polymer, which offer high flexibility and withstand repeated bending cycles. The table below highlights key technological advancements that drive this transformation:

| Advancement | Impact in Medical and Automotive Sectors |

|---|---|

| Advanced Substrate Materials | Endure harsh environments, repeated bending, high frequencies |

| Manufacturing Innovations | Enable scalable, precise, and cost-effective production |

| Automation and Quality Control | Achieve high reliability and low defect rates |

| Biocompatibility and Stretchability | Allow safe use in wearable and implantable devices |

The fpc system and printed circuit boards now meet strict demands for flexibility, durability, and safety.

Key Takeaways

- Flexible printed circuits enable compact, reliable, and durable designs in medical and automotive devices.

- In medical devices, FPCs improve patient comfort by fitting curved body parts and support continuous health monitoring.

- Automotive electronics benefit from FPCs through space-saving layouts, weight reduction, and resistance to harsh conditions.

- Advanced materials and manufacturing ensure FPCs meet strict safety, biocompatibility, and durability standards.

- Ongoing innovations in both sectors drive miniaturisation, better performance, and easier assembly for future devices.

FPC System in Medical Devices

Applications in Healthcare

The fpc system has become essential in modern healthcare. Medical engineers use flexible printed circuit boards in a wide range of devices. These include wearable monitors, implants, imaging equipment, and diagnostic tools. For example, a wearable ultrasound system for Alzheimer’s therapy uses a flexible honeycomb-shaped patch and an ultrasonic drive circuit on an FPC board. This design allows noninvasive, continuous brain stimulation and real-time monitoring of patient biomarkers. The patch’s flexibility and biocompatibility make it suitable for direct skin contact, which is vital for wearable monitors and implants. Flexible PCBs also support multifunctionality and energy efficiency, making them ideal for diagnostic tools and imaging equipment. These advances show that the fpc system enables miniaturised, intelligent medical devices that can monitor, treat, and image patients continuously.

Note: The flexible PCB market is growing rapidly, with projections reaching nearly $43 billion by 2029. Medical devices and healthcare wearables are major drivers of this expansion, reflecting the increasing demand for advanced, patient-friendly technology.

Flexible PCB Benefits

Flexible PCBs offer several advantages in medical devices. Their bendable design fits unconventional shapes, which is important for wearable and implantable devices. Devices can conform to curved or irregular body parts, improving patient comfort during long-term use. High-Density Interconnect (HDI) technology allows more components in a smaller space, supporting miniaturisation without sacrificing performance. Heart monitors and glucose meters, for example, must be compact, lightweight, and reliable. By combining flexible PCB technology with HDI design, engineers can integrate sensors, wireless modules, and processors into slim devices. Patients can wear these devices all day, which enables continuous health monitoring.

Flexible printed circuit boards also provide a high degree of reliability. In critical medical applications, they can endure over 100,000 bending cycles without failure. Advanced materials, such as PTFE-based laminates, ensure signal integrity in high-frequency uses. Security features like secure boot and hardware security modules protect device integrity. These qualities make flexible PCBs a trusted choice for life-saving medical equipment.

Addressing Medical Challenges

Medical devices must meet strict requirements for safety and performance. Flexible PCBs achieve biocompatibility through careful material selection and testing. Manufacturers follow ISO 10993 standards, which include checks for chemical composition, toxicity, and mechanical strength. This process ensures that materials do not release harmful substances or cause adverse reactions. Regulatory approval from bodies like the FDA and EU MDR depends on these standards.

| Requirement Aspect | Details |

|---|---|

| Surface Treatment | Immersion gold plating, 2 micro-inch thickness over nickel layer (≥ 5μm nickel, ≥ 0.05μm gold) |

| Corrosion Resistance | Withstands frequent wiping with alcohol, iodine vapours, hydrogen peroxide (no corrosion after 1000 wipes) |

| Biocompatibility Standard | Complies with ISO 10993, ensuring no heavy metal precipitation and safety for human contact |

| Electrical Performance | Contact resistance ≤ 8mΩ, ensuring low transmission loss and detection error ≤ 0.5% |

| Sterilisation Durability | Gold layer corrosion resistance supports frequent disinfection with common medical disinfectants |

Sterilisation is another key challenge. Flexible PCBs use corrosion-resistant gold plating, which withstands repeated cleaning with alcohol and other disinfectants. This durability ensures a secure connection and reliable performance even after many sterilisation cycles.

Medical devices also face higher costs in pcb manufacturing compared to traditional printed circuit boards. Flexible PCBs use more expensive materials and require complex processes, such as laser drilling and controlled impedance testing. Strict quality standards, like IPC Class 3, add to the cost but guarantee reliability.

Common failure modes include mechanical fragility, poor adhesion of conductive layers, and thermal damage during assembly. Engineers address these issues by selecting high-quality materials, optimising design, and using advanced manufacturing techniques. Rigorous testing and compliance with standards like IPC-6013 ensure that flexible PCBs meet the demands of critical medical applications.

FPC System in Automotive Electronics

Printed Circuit Boards in Vehicles

Automotive engineers rely on printed circuit boards to power a wide range of vehicle systems. The fpc system supports advanced interconnects, sensors, and antennas, which are essential for modern vehicles. Flexible printed circuit boards fit into tight spaces and allow creative layouts for complex electronics. These boards appear in many areas of a car:

- Sensors for tyre pressure, airbag deployment, and exhaust monitoring

- Infotainment systems, including touchscreens and head-up displays

- Ambient lighting in dashboards, doors, and seats

- Connectivity modules, such as antennas for telematics and wireless communication

- Power management and engine control units

The table below highlights key application areas and their functions:

| Application Area | Description and Examples |

|---|---|

| Sensors | Used in safety systems such as tyre pressure monitoring and airbag deployment. Printed sensors enhance safety features. |

| Displays | Printed electronics used in infotainment systems, head-up displays, and instrument clusters. |

| Lighting | Includes ambient lighting solutions integrated into dashboards, doors, and consoles. |

| Connectivity Components | Printed antennas for improved vehicle connectivity. |

| Driving Forces | Lightweighting for fuel efficiency, cost reduction via roll-to-roll manufacturing, design flexibility, and increased functionality. |

| Advanced Systems | Integration in ADAS, electric/hybrid vehicles, and infotainment emphasising safety, lighting, and sensors. |

The global advanced PCB market reached USD 70 billion in 2024. Flexible printed circuit boards now represent a significant part of this market, especially as electric vehicles and advanced driver-assistance systems become more common. Polyimide materials, known for their flexibility and heat resistance, continue to grow in popularity for automotive uses.

Automotive Benefits

Flexible printed circuit boards offer several advantages in automotive electronics. Their ability to bend and fold allows engineers to design compact modules that fit into irregular spaces. This feature is vital for navigation systems, entertainment consoles, and control modules, where space is limited. The lighter polymer core, such as polyimide film, reduces the overall weight of the electronic system. Rigid-flex PCBs combine rigid and flexible sections, which eliminates the need for loose wires and connectors. This design simplifies assembly and further reduces both weight and space.

Key benefits include:

- Space-saving layouts for tight or curved areas

- Weight reduction, which improves fuel efficiency

- Simplified wiring, leading to fewer connection failures

- Durability against vibration and shock

Overmolded PCBs, which have a protective plastic or elastic layer, resist heat, oil, and vibration. This makes them ideal for harsh engine environments. Overmolding also provides waterproofing and dustproofing, meeting high protection standards such as IP67 and IP68. These features ensure failure-free operation even under extreme environmental conditions.

Note: Rigid-flex and overmolded PCBs help automotive manufacturers achieve excellent thermal management. They spread heat efficiently and protect sensitive components from thermal stress.

Overcoming Automotive Challenges

Automotive electronics face many challenges, including vibration, temperature extremes, and long-term reliability. Vehicles operate in extreme operating conditions, such as rapid temperature changes and constant mechanical stress. Engineers must design printed circuit boards that withstand these harsh environments.

The table below outlines common challenges and solutions:

| Challenge Aspect | Description | Mitigation Strategies |

|---|---|---|

| Vibration | Mechanical stress from vibrations can loosen components or crack solder joints. | Use surface-mount components, secure large parts with adhesives, avoid placing parts near edges. |

| Temperature Extremes | Swings from -10°C to 50°C cause thermal expansion and fatigue. | Use robust materials, add heat sinks and thermal vias, optimise copper planes for heat dissipation. |

| Thermal Management | Heat from power components can degrade reliability. | Attach heat sinks, add thermal vias, use copper pours, monitor with simulation tools. |

| Environmental Stress Testing | Boards tested for temperature cycling, humidity, and vibration to ensure reliability. | Design for vibration resistance and thermal stability, pass rigorous tests for long-term durability. |

Common failure modes include delamination at the rigid-flex interface, trace cracking in dynamic flex areas, and plated through-hole barrel cracking. Engineers address these issues by selecting compatible materials, using rolled-annealed copper, and maintaining proper bend radii. They also avoid routing traces perpendicular to fold lines and reinforce rigid areas with adhesives. These strategies help maintain reliability and extend the lifespan of automotive electronics.

Automotive manufacturers invest in advanced pcb manufacturing processes to meet strict quality standards. They test boards for resistance to vibration, heat, and moisture. Overmolded PCBs provide extra protection, making them more stable and durable than traditional enclosures. This approach ensures that printed circuit boards continue to perform reliably in extreme environmental conditions.

Flexible PCB Technology: Medical vs Automotive

Shared Advantages

Flexible PCB technology delivers significant value in both medical and automotive sectors. Engineers in both fields benefit from design freedom, allowing them to create devices that fit into tight or irregular spaces. High-density assembly enables more components to fit onto smaller boards, supporting miniaturisation and advanced functionality. Flex circuits can bend and twist, making them ideal for wearable medical monitors and compact automotive sensors.

Both sectors rely on printed circuit boards for reliability and durability. Automated quality control and advanced inspection methods, such as cyclic bending tests, ensure that devices meet strict safety and performance standards. Material innovations, including polyimide and liquid crystal polymer, provide thermal stability and flexibility. These materials help devices withstand harsh environments, whether inside the human body or under a car bonnet.

Note: Miniaturisation techniques, such as embedded passives and 3D stacking, reduce board thickness and improve integration. This supports the trend towards smaller, smarter devices in both industries.

Sector Innovations

Medical and automotive sectors each require unique adaptations of flexible PCB technology. In healthcare, engineers use biocompatible flexible PCBs with special coatings for direct skin contact and short-term implants. Manufacturing methods like Roll-to-Roll processing and Laser Direct Imaging allow high-volume, precise production for medical wearables. Stretchable electronics can elongate up to 50% without losing conductivity, enabling skin-like sensors for continuous health monitoring. Transparent flexible PCBs combine optical clarity with flexibility, improving the design of compact medical devices and enhancing light transmission for optical applications.

In the automotive sector, engineers develop flexible PCBs with single-layer designs optimised for weak signal transmission. These designs use parallel wiring to reduce signal delay and interference. Surface treatments, such as electro-hard gold plating, provide abrasion and corrosion resistance, ensuring long service life even in harsh conditions. Rigid-flexible printed circuit boards combine rigid and flexible layers, offering durability and space-saving layouts for sensors and control units. Specialised assembly and testing methods guarantee that these boards meet the high standards required for automotive reliability.

| Sector | Unique Innovations |

|---|---|

| Medical | Biocompatible coatings, stretchable electronics, transparent flexible PCBs, miniaturisation |

| Automotive | Single-layer sensor designs, electro-hard gold plating, rigid-flexible PCBs, advanced assembly |

Flexible PCB technology continues to transform medical and automotive sectors. Engineers achieve miniaturisation, reliability, and sustainability through advanced materials and design. Medical devices benefit from innovations such as hybrid connectors and simplified assembly, as shown below:

| Future Trend / Innovation | Description |

|---|---|

| Miniaturisation | Smaller connectors for portable devices |

| High-Speed Data Transmission | Over 10Gb/s with strong shielding |

| Rugged Durability | Enhanced shock and vibration resistance |

| Simplified Assembly | Tool-free connectors for robotic installation |

| Hybrid Connectors | Combined signal and power delivery |

Automotive systems adopt high-precision FPCs for real-time data and user-friendly interfaces. Sustainability improves with lightweight designs and eco-friendly materials. Future developments will drive further innovation and reliability across both industries.

2025-08-04

2025-08-04

BEST

BEST

.png)

.png)

.png)

.png)

.png)