You must follow strong flex pcb design rules to keep things safe and working well in aerospace and drone systems. Reliability is very important for every mission. Making things lighter helps save fuel and makes things faster. Using space well lets you add more technology to small places. Recent studies show that every gram is important. Launch costs can be thousands for each kilogram. By picking smart designs and new materials, you can meet strict rules for safety, strength, and handling tough environments.

Key Takeaways

- Reliability is very important. Always add backup parts so circuits work each time. Use light materials like polyimide to save weight and space. Follow strict bend radius rules to stop damage to circuits when used. Test everything well under fake conditions to find weak spots before using it for real. Work with suppliers early to make design and making better.

Flex PCB Design Rules Overview

Reliability and Redundancy

Reliability is very important in flex PCB design for aerospace and drone systems. Circuits must work every time a flight happens. Redundancy means you have backup parts if one fails. Staggering traces in flexible areas helps stop cracks. Do not put vias in places that bend. Keep vias at least 50 mils from the flex-rigid edge. Mechanical tests are needed to check strength. You should do stress tests and heat tests to see if the board can handle hard conditions.

Tip: Put conformal coatings on your circuits. This protects them from water and chemicals. It helps your system stay safe in tough places.

| Design Rule | Description |

|---|---|

| Bend Radius | The smallest bend is 10 times board thickness for static use, 100 times for moving use. |

| Trace Staggering | Stagger traces to lower stress and stop cracks. |

| Via Placement | Keep vias away from bends and flex-rigid edges. |

| Thermal Management | Use thermal vias and materials that spread heat. |

| Environmental Resilience | Use coatings to protect from water and chemicals. |

| Mechanical Testing | Do stress and heat tests on the board. |

Signal Integrity and EMI

Signal integrity means signals must stay clear for good data. Signals must be steady, especially for radar or satellite use. Flexible parts can make signals weaker because the board bends. Signals near bends can lose quality. Aluminium PCBs help stop signal loss and electromagnetic interference (EMI). This lowers errors and helps missions succeed.

- Signal integrity is needed for fast data.

- Flexible boards can change signal quality.

- Signals near bends can get worse.

- Aluminium PCBs lower EMI and signal loss.

Weight and Space

Flex pcb design rules help save weight and space in aerospace and drone systems. You can make boards 20% lighter than regular rigid PCBs. Space savings can be up to 50%. This lets you put more technology in small spaces and use less fuel.

| Weight Reduction | Space Savings |

|---|---|

| 20% or more | Up to 50% |

Rigid-flex PCBs give you the good parts of both flexible and rigid boards. You can use them to fit more parts in small spaces. Using strong materials like polyimide gives better heat resistance, flexibility, and strength. Polyimide is better than FR4 and PTFE for heat and chemical safety. Always follow bend radius rules: 10 times thickness for static, 100 times for moving. These rules help stop damage and make circuits last longer.

Importance of Design Rules

Environmental Stresses

Designing electronics for aerospace and drone systems is tough. There are many challenges from the environment. High altitude can harm circuits. Fast temperature changes can also cause problems. Strong vibrations shake the boards and may break them. Moisture and chemicals can make boards unsafe. You need materials that can handle these stresses. Polyimide and other strong materials help circuits work in hard places. You should test your boards in fake environments to see if they last. Following flex pcb design rules keeps your electronics safe from breaking.

Note: Testing boards in tough conditions shows weak spots before use.

Design rules help make aerospace and drone electronics safer and more reliable:

| Rule | Description |

|---|---|

| 1 | Follow IPC-A-610 Class 3 Standards for Quality: This makes sure solder joints and assembly are strong against heat and force. |

| 2 | Focus on Thermal Management for Extreme Conditions: This stops parts from getting too hot, so they work well in high heat. |

| 3 | Pick Materials for Durability in Harsh Environments: Strong materials fight temperature changes and chemical damage. |

| 4 | Improve Routing for Signal Integrity and Reliability: Good routing keeps signals clear and lowers interference. |

| 5 | Design for Vibration and Mechanical Stress: This helps stop parts from falling off or traces from cracking. |

| 6 | Add Redundancy for Fail-Safe Operation: If one part fails, others keep working, which is important for safety. |

| 7 | Test Well Under Simulated Extreme Conditions: Lots of testing makes sure boards work in tough aerospace places. |

Compliance Needs

You must follow strict rules when designing flex PCBs for aerospace and drones. These rules help keep things safe and high quality. IPC Class 3/3A means your boards must be very reliable. AS9100 checks risk and makes sure quality is good. Groups like the FAA and EASA want lots of tests and paperwork. You need to follow these rules to get your products approved.

| Compliance Standard | Description |

|---|---|

| IPC Class 3/3A | Makes sure aerospace PCBs are very reliable, with careful design and checks to stop problems. |

| AS9100 | A certificate based on ISO 9001, it checks risk and quality for aerospace uses. |

| FAA and EASA | These groups make sure parts are tested, checked, and approved for aerospace. |

Tip: Always keep notes about your design and tests. This helps you pass checks and makes customers trust you.

Key Design Considerations

Material Selection

You must pick the best materials for your flex PCBs. Polyimide is the top choice for aerospace and drone use. It can handle very hot and cold temperatures. It bends easily and does not break. It also stands up to chemicals and shaking. Polyester (PET) costs less and is good for simple jobs. But it does not protect as well as Polyimide. Rigid-flex designs mix hard and bendy parts. This lets you put heavy parts in small spaces.

| Material | Advantages |

|---|---|

| Polyimide (PI) | Wide temperature range, excellent flexibility, chemical, vibration, and shock resistance. |

| Polyester (PET) | Cost-effective, decent flexibility, best for basic circuits. |

| Rigid-Flex | Mixes rigid and flexible sections for complex layouts and tight spaces. |

Stackup and Layers

How you build your board changes how it bends and lasts. A good stackup lets your board bend without breaking. It keeps signals clear, even when the board bends. If you plan your layers well, you can stop cracks and peeling.

| Benefit | Description |

|---|---|

| Mechanical Flexibility | Lets the board bend as needed without damage. |

| Signal Integrity | Keeps signals strong and clear in bending areas. |

| Durability | Lowers the risk of cracks and delamination in moving parts. |

| Lifespan Extension | Reduces signal loss over time, making your board last longer. |

Bend Radius

You need to follow bend radius rules to keep circuits safe. If you bend the board too much, copper lines can break. Here are some easy rules: For 1-2 layer boards, bend at least 6 times the thickness. For 3 or more layers, bend at least 12 times the thickness. Most flexible boards do well with a bend radius 10 times the thickness.

Tip: A bigger bend radius helps your board last longer.

Thermal Management

Heat can hurt your circuits fast. Use materials that spread heat, like low CTE dielectrics and thick copper. Add thermal vias and heat sinks to move heat away. Put hot parts together to control heat better. Passive systems, like heat pipes, work without power. Active systems, like heaters, help in very cold places.

Chemical Resistance

Aerospace and drone places have water, dust, and chemicals. Polyimide film protects against heat and chemicals. It keeps your board bendy and strong. Conformal coatings add more protection. They block water and dust. These things help your flex PCBs last longer and work safely in tough places.

Application Strategies

Lightweighting

Flexible PCBs help make drones and aircraft lighter. These boards do not need heavy connectors or wires. You can build small designs that fit tight spaces. Flexible PCBs bend and twist but do not break. This keeps your system strong in hard conditions. They can change shape, so you can make tiny systems. Saving weight and space is very important.

| Advantage | Description |

|---|---|

| Space-saving properties | Flexible PCBs remove big connectors and wires. This lets drones have small designs. |

| Mechanical stress resistance | They bend and twist but stay strong in tough places. |

| Compactness and reliability | Their shape-changing ability helps make tiny systems. This is key for saving weight. |

Tip: Lighter drones and planes use less fuel and go faster. This is important for flying machines.

Vibration Resistance

Electronics need protection from shaking and vibration. Flexible PCBs bend instead of cracking when shaken. Wider traces help spread electric current better. This makes the board last longer. Placing parts carefully keeps them safe. Fewer connection points mean fewer chances for problems. Small and light boards work best where there is lots of vibration.

| Design Principle | Contribution to Vibration Resistance |

|---|---|

| Use of Flexible Materials | The PCB bends but does not break, lowering stress. |

| Wider Traces | Electric current spreads out, making the board stronger. |

| Careful Component Placement | Fewer weak spots, so parts stay safe. |

| Fewer Connection Points | Less chance for problems, so the board works better. |

| Compact and Lightweight Nature | Small boards are good when space and weight matter. |

Space Optimisation

Flexible PCBs let you fit more tech into small spaces. These boards work for tricky and 3D designs. You can use curved and odd shapes. Flexible PCBs fit in panels, antennas, and avionics boxes. They save up to 90% of space and 75% of weight in aircraft.

- Tricky and 3D designs fit into hard layouts.

- Curved shapes work for plane panels and satellites.

- Odd shapes are good for cockpits and antennas.

- Flexible PCBs match aerodynamic needs and wearable gadgets.

Saving space and weight lets you add more features without making things heavier.

Integration

Flexible PCBs help your system work better when you use them. Single-layer boards give strong electric links and steady power. Their small size fits into many parts. Flexible PCBs survive vibration, shock, and radiation. They lower weight and help save fuel. You can use them in tight places, which helps with 3D packing. Signals stay clear, so avionics and navigation work well.

- Rigid-flex PCBs handle shocks, so they are good for control and navigation.

- Being light means flight gear is not weighed down.

- Good signals help keep communication safe.

Flexible PCBs fit aircraft shapes, so you can use space well and make flying smoother.

Challenges and Solutions

Mechanical Fatigue

Mechanical fatigue happens when flexible PCBs bend or twist a lot. This can make small cracks in copper lines. Layers might start to peel apart. You can stop this by using rolled annealed copper. This copper bends without breaking. Strong adhesives or adhesiveless laminates keep layers together. Pick materials that expand at the same rate when hot or cold. This keeps stress low when temperatures change fast.

- Use rolled annealed copper to stop tiny cracks.

- Pick strong adhesives or adhesiveless laminates to keep layers together.

- Choose materials that expand the same amount to lower stress.

You should test your boards by bending them many times. Shake them to see if cracks or peeling happen. Vibration tests show if your circuits can survive real flights. Flexible circuits can wear out faster if temperatures change a lot. Big movements and many bends can make the board last less time.

Tip: Always test your boards by bending and shaking before using them in drones or planes.

Manufacturing Tolerances

You must control how closely your boards are made to the right size. Flexible PCBs in aerospace must handle very hot and cold temperatures. They need to survive strong shaking up to 20G. Use high-Tg FR-4 or polyimide for strong boards. These materials do not bend or warp easily. A glass transition temperature of 170°C or more stops layers from peeling. Impedance control within ±10% keeps signals clear. This is very important for military and flight systems.

- Temperature range: -55°C to 125°C

- Vibration resistance: up to 20G

- Material choice: high-Tg FR-4 or polyimide

- Glass transition temperature: 170°C or more

- Impedance control: ±10% tolerance

Quality Assurance

You need good checks to make sure your boards are safe for flight. Start by looking at the board and checking all connections. Test signal quality and speed with special tools. Environmental tests check if the board can handle heat, cold, wet, and shaking. Flight simulations show if the board stays stable and cool during real missions.

| Testing Stage | Description |

|---|---|

| Preliminary Electrical and Functional Testing | Look at the board, check connections, and test firmware. |

| Signal Integrity and High-speed Performance | Test impedance and signal quality with special tools. |

| Environmental Durability and Structural Strength | Test for heat, wet, shock, and vibration resistance. |

| Flight Simulation and Field Verification | Pretend to fly to check if the board stays stable and cool. |

Note: Careful testing and strong materials help you meet strict aerospace rules and keep your systems safe.

Implementing Flex PCB Design Rules

Manufacturability

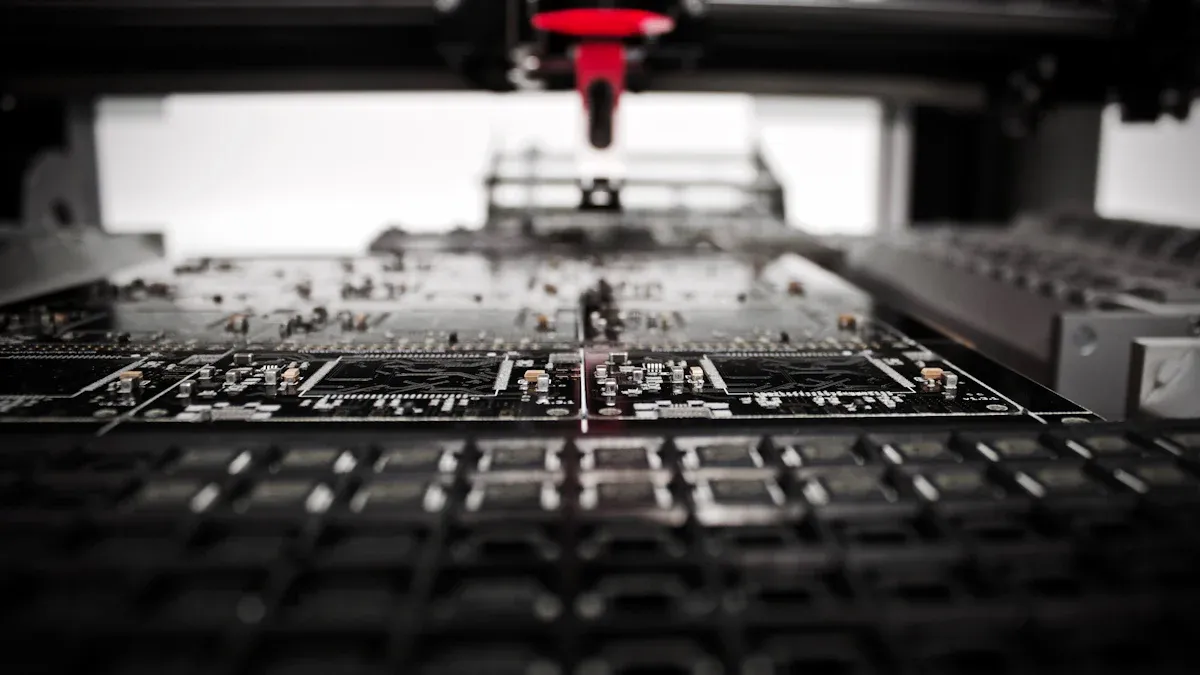

You must make designs that are simple to build and follow strict rules. Good design choices help your boards work well during flights. Here are some things you should do: Use Design for Manufacturing (DFM) ideas. This helps you get the right sizes for traces and vias. Think about heat, signal quality, and board strength when you plan. Use exact methods like automated solder paste printing and pick-and-place assembly. These ways make your boards better and more reliable. If you think about manufacturability early, you can stop expensive mistakes later. Your boards will pass tests and last longer in hard places.

Tip: Speak with your manufacturer early. This helps you find problems before they cost a lot.

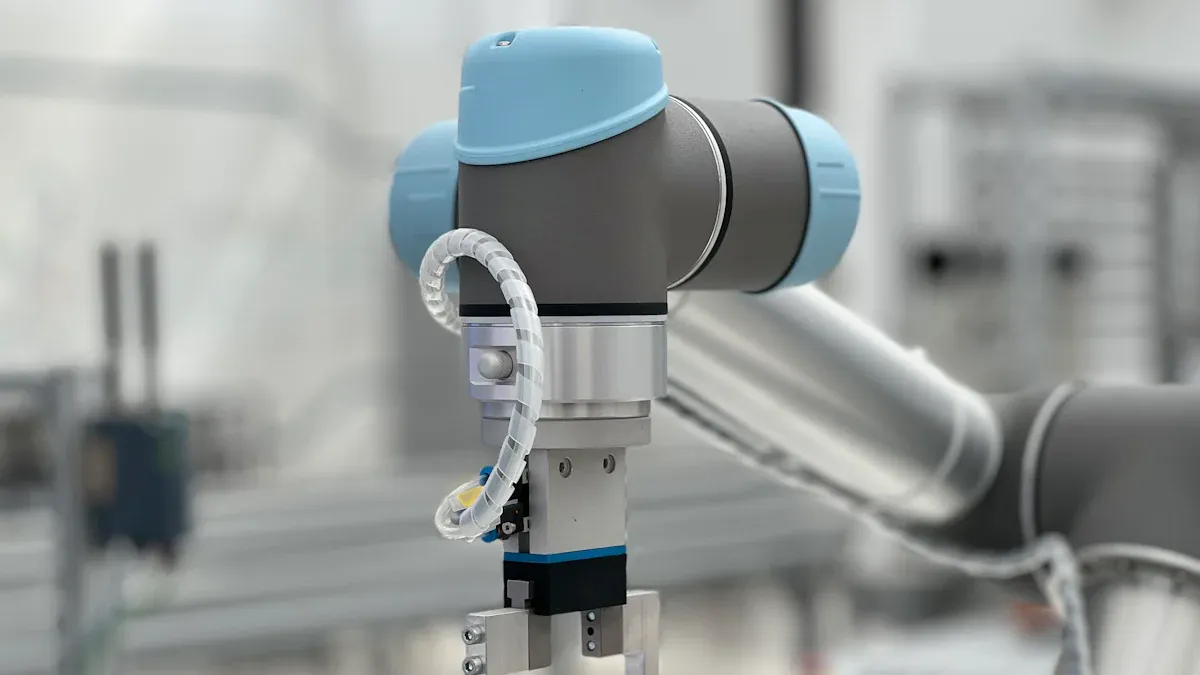

Supplier Collaboration

Working with your suppliers helps make boards safer and more reliable. You get better results when you share ideas and feedback. The table below shows how working with suppliers helps your project:

| Evidence Type | Description |

|---|---|

| Design Feedback | Early teamwork helps you fix problems quickly and improve your design. |

| Risk Mitigation | Finding issues early lets you change things before they cost more. |

| Communication and Feedback Loops | Clear talks help everyone solve problems fast and stay on track. |

| Regular Check-ins | Meetings help your project move forward and handle challenges. |

| Real-Time Data Sharing | Sharing data quickly helps you decide faster and keeps things smooth. |

Strong partnerships help you make better flex PCBs. You also make sure your flex pcb design rules fit what your supplier can do.

Documentation

You need clear and full documents for every part of your project. Good records help you pass checks and keep your work safe. Write down your design choices, test results, and any changes you make. Use easy drawings and notes so others can understand your work. Keep all records up to date. This makes it easier to fix problems and answer questions from inspectors or customers.

Note: Good records show you follow the rules and help you earn trust from clients and regulators.

You can make aerospace and drone systems work better by using strong flex PCB design rules. Picking light and strong materials, like carbon fibre or titanium, helps you lower weight and make things last longer. Rigid-flex PCBs use fewer connectors and wires, so you save space and your drone can fly for longer. It is important to manage heat and stop rust in tough places.

- Rigid-flex PCBs help stop problems from shaking and make things lighter.

- Good material choices help your system stay steady and make batteries last longer.

- Flex circuits fit in small spaces and do not break when shaken.

Look for more information if you want to learn about flexible circuit design for important projects.

2025-09-08

2025-09-08

BEST

BEST

.png)

.png)

.png)

.png)

.png)