You face a critical choice when selecting materials for flexible printed circuit boards. PET material pcb offers you a cost-effective option with excellent flexibility. Polyimide provides superior thermal stability and higher performance, but it comes at a higher price. Your decision on material affects durability, heat resistance, and overall product reliability. Material selection shapes how well your design meets its intended purpose.

Key Takeaways

- Selecting the right material for flexible PCBs impacts durability, heat resistance, and overall reliability. Consider your application's specific needs.

- PET offers a cost-effective solution with good flexibility, making it ideal for consumer electronics. Use it for high-volume production to save costs.

- Polyimide excels in thermal stability and mechanical strength, suitable for demanding environments like aerospace and automotive. Choose it for high-temperature applications.

- PEN provides a balance between cost and performance, making it a good choice for moderate heat applications. Assess your needs to find the right fit.

- Always check for RoHS compliance and future-proofing when selecting materials. This ensures your design meets industry standards and adapts to future requirements.

Flex PCB Material Comparison Overview

Key Factors in Material Selection

When you choose a material for your flexible PCB, you must weigh several important factors. Each decision affects the performance, reliability, and cost of your final product. Engineers often focus on the following aspects:

| Factor | Description |

|---|---|

| Copper thickness | Affects current carrying capacity, signal integrity, and heat dissipation. |

| Substrate material | Provides mechanical support and electrical insulation; common types include FR-4, PTFE, and metal core. |

| Thermal performance | Important for heat-sensitive applications; involves thermal conductivity and CTE. |

| Dielectric constant | Indicates ability to store electrical energy; lower values are better for high-frequency applications. |

| Cost | Varies based on material type and thickness. |

| Environmental impact | Considers material composition, recyclability, and disposal options. |

| RoHS compliance | Ensures materials meet regulations on hazardous substances. |

| Signal integrity | Measures how well a PCB transmits signals; influenced by dielectric constant, copper thickness, and trace geometry. |

| Future-proofing | Selecting materials that can accommodate future upgrades or changes. |

You should pay close attention to substrate choice, as it determines the mechanical flexibility and electrical insulation of your circuit. Copper thickness also plays a key role in current handling and heat dissipation. If your design requires high-frequency operation, you need to consider the dielectric constant. Lower values help maintain signal integrity. Cost and environmental impact influence your decision, especially for large-scale production.

Thickness is another critical parameter. Comparing pet material pcb and polyimide flex pcb thickness helps you balance flexibility with mechanical strength. Thinner substrates allow tighter bends but may reduce durability. You must select the right thickness to match your application's needs.

Tip: Always check for RoHS compliance and future-proofing when selecting materials. This ensures your design meets industry standards and remains adaptable to future requirements.

Performance and Cost Summary

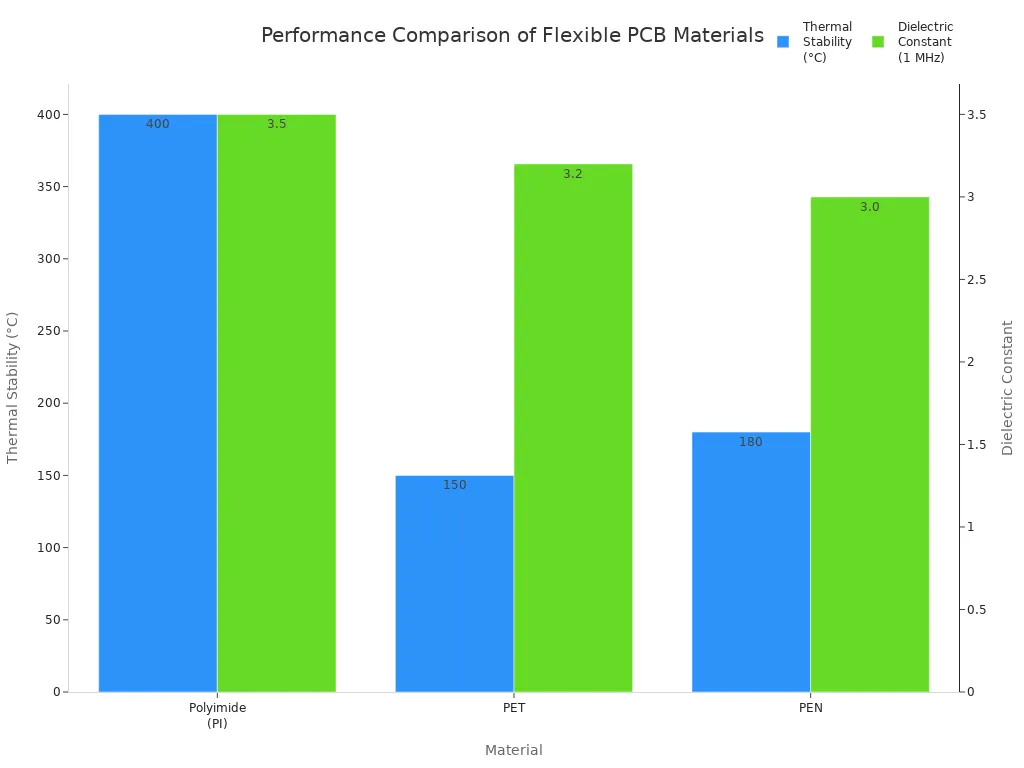

You will notice clear differences when you compare the main flexible PCB materials. Polyimide, PET, and PEN each offer unique properties. The table below summarises their key characteristics:

| Material | Typical Thickness (μm) | Thermal Stability (°C) | Dielectric Constant (at 1 MHz) | Cost | Best Applications |

|---|---|---|---|---|---|

| Polyimide (PI) | 12.5 - 125 | Up to 400 (short-term) | 3.5 | High | Aerospace, Automotive, Industrial |

| PET | 25 - 125 | Up to 150 (continuous) | 3.2 | Low | Consumer Electronics, Keypads |

| PEN | 25 - 125 | Up to 180 (continuous) | 3.0 | Medium | Automotive Sensors, Moderate Heat Uses |

Polyimide stands out for its high thermal stability and wide thickness range. You should choose it for demanding environments, such as aerospace or automotive systems. PET offers a lower-cost solution with good flexibility, making it ideal for consumer electronics. PEN provides a middle ground, with moderate heat resistance and cost.

When you conduct a flex pcb material comparison, you must look beyond just cost. Thermal stability, dielectric constant, and application suitability all play vital roles. Polyimide flex pcb thickness can reach very thin levels, supporting complex, high-density designs. PET and PEN also offer a range of thicknesses, but you may need to compromise on heat resistance or mechanical strength.

You should always match the material to your application's requirements. If you need high flexibility and low cost, PET may suit you best. For high-temperature or mission-critical uses, polyimide remains the top choice. PEN works well for moderate environments where you need a balance between performance and price.

PET Material PCB Properties and Applications

PET Flexible PCB Thickness and Range

You often see pet flexible pcb thickness as a key specification in consumer electronics. Manufacturers select thickness based on the required flexibility and mechanical strength. You can find PET flexible PCBs in the following thickness range:

- 25 μm (1 mil)

- 50 μm (common choice)

- 125 μm (5 mil)

Thinner options allow you to create circuits that bend easily. Thicker PET material pcb provides more durability for demanding environments. When you perform a flex pcb material comparison, thickness remains a critical factor for both design and reliability.

Advantages of PET Material PCB

You benefit from several advantages when you choose pet material pcb. PET offers excellent flexibility, which suits applications where you need repeated bending. You also gain cost savings, as PET is less expensive than polyimide. PET provides good electrical insulation and chemical resistance. You can use PET for designs that do not require high thermal stability. PET flexible pcb thickness options give you versatility for different product requirements.

Tip: PET material pcb works well for high-volume production, especially when you need to keep costs low.

Limitations of PET Material PCB

You must consider some limitations before selecting PET. PET does not match the thermal stability of polyimide. You may face restrictions in high-temperature environments. PET flexible pcbs can lose mechanical strength if you use very thin substrates. You should compare polyimide flex pcb thickness with PET to ensure your design meets durability standards. PET also has lower resistance to harsh chemicals compared to some alternatives.

Typical PET FPC Applications

You find PET FPCs in many industries. The table below shows common uses in automotive and medical sectors:

| Sector | Applications |

|---|---|

| Automotive | Airbag systems, GPS devices, Infotainment systems |

| Medical | Hearing aids, Pacemakers, Diagnostic equipment |

You also see PET material pcb in consumer electronics, such as keypads and display modules. Flexible pcbs with PET substrates support lightweight and compact designs. You can rely on PET for applications where moderate heat resistance and high flexibility are required.

Polyimide Flex PCB Thickness and Features

Polyimide Material Properties

You will find polyimide stands out for its excellent thermal stability and mechanical strength. Polyimide films maintain their shape and performance even under high temperatures. This property makes them a top choice for demanding environments. Flexible polyimide films resist chemicals and moisture, which helps protect your circuits from harsh conditions. You can rely on polyimide to deliver consistent electrical insulation and flexibility.

Polyimide materials excel in thermal stability, which is crucial for flexible PCB manufacturing. You can trust these films to withstand extreme heat where other materials might fail.

Benefits of Polyimide FPC

You gain several advantages when you use polyimide FPCs in your designs. Polyimide supports higher operating temperatures, which allows your circuits to function in extreme environments. The material’s ruggedness means your circuits resist vibration and shock. You also save space and weight because polyimide substrates are thin and lightweight. This enables you to bond circuits within compact product structures.

| Benefit | Description |

|---|---|

| Higher operating temperature | Polyimide materials provide better thermal stability, allowing circuits to withstand extreme heat. |

| Ruggedness | Flat foil conductors dissipate heat better and are more resistant to vibration and shock. |

| Space saving | Thin dielectric substrates enable bonding circuits within product structures. |

| Weight saving | Reduced weight due to fewer connectors and smaller conductors. |

| Increased product reliability | Elimination of traditional connectors enhances reliability by reducing assembly issues. |

Drawbacks of Polyimide FPC

You should consider some limitations before choosing polyimide. The cost of polyimide is higher than PET or PEN. You may also find that polyimide absorbs moisture more easily, which can affect performance if not managed properly. Processing polyimide requires careful handling because of its sensitivity to certain chemicals during manufacturing.

Note: Polyimide offers superior performance, but you must balance this against higher material and processing costs.

Common Polyimide FPC Uses

You will see polyimide FPCs in many high-reliability applications. These include:

- Aerospace systems, such as onboard weapon navigation and sensors

- Automotive radar modules

- Mobile phone and digital cameras, including thermal imaging devices

- Medical equipment, such as endoscopes and other medical devices

- Fibre optic transmission systems

- Portable ATM terminals

- Military aircraft

Polyimide’s unique properties make it the preferred choice for industries where reliability, heat resistance, and durability are essential.

Other Flexible PCB Materials

PEN and Other Alternatives

You may encounter polyethylene naphthalate (PEN) as a popular alternative to PET and polyimide. PEN offers a unique balance between cost and performance. You also find other materials such as PTFE (polytetrafluoroethylene), LCP (liquid crystal polymer), and even flexible ceramics in specialised applications. Each material brings its own set of strengths and weaknesses. You should consider these options when your design requirements do not fit the standard PET or polyimide profiles.

Properties and Suitability

PEN stands out for its improved thermal stability compared to PET. You can use PEN in environments where temperatures reach up to 180°C. This makes it suitable for automotive sensors and moderate heat applications. PTFE provides excellent chemical resistance and low dielectric constant. You often see PTFE in high-frequency circuits. LCP offers outstanding moisture resistance and dimensional stability. You may select LCP for advanced communication devices. Flexible ceramics deliver high-temperature performance, but you usually reserve them for niche markets due to their cost.

| Material | Max Continuous Temp (°C) | Chemical Resistance | Dielectric Constant | Typical Use Case |

|---|---|---|---|---|

| PEN | 180 | Good | 3.0 | Automotive sensors, displays |

| PTFE | 260 | Excellent | 2.1 | RF circuits, aerospace |

| LCP | 220 | Excellent | 2.9 | Antennas, high-speed data lines |

| Ceramic | 300+ | Excellent | 6.0 | Extreme environments |

Note: You should always match the material’s properties to your application’s demands. This ensures reliability and cost-effectiveness.

Pros and Cons

You gain several benefits by exploring alternatives in your flex pcb material comparison. PEN gives you better heat resistance than PET at a moderate price. PTFE and LCP provide superior chemical resistance and electrical performance, but you pay more for these features. Flexible ceramics withstand extreme temperatures, but you face higher costs and limited flexibility. You must weigh the performance-to-cost ratio for each option. You also need to consider chemical resistance if your product operates in harsh environments. By understanding these trade-offs, you make informed decisions when selecting materials for flexible pcbs.

Side-by-Side Flex PCB Material Comparison

Thickness and Flexibility

You must consider thickness and flexibility when selecting a flexible PCB material. These factors determine how well your circuit bends and fits into compact spaces. Polyimide films offer a wide range of thicknesses, from 12.5 μm to 125 μm. This range supports both ultra-thin and robust designs. PET substrates usually come in thicknesses between 25 μm and 125 μm. PET provides good flexibility, but repeated bending can reduce its lifespan. PEN sits in a similar range to PET, but with slightly improved durability.

| Material | Typical Thickness Range (μm) | Flexibility Level |

|---|---|---|

| Polyimide | 12.5 – 125 | Excellent |

| PET | 25 – 125 | Good |

| PEN | 25 – 125 | Good |

You should match the thickness to your application's needs. Thinner materials allow tighter bends, but may sacrifice mechanical strength.

Thermal Stability

Thermal stability is crucial for circuits exposed to heat. Polyimide withstands temperatures up to 400°C for short periods. This makes it ideal for harsh environments. PET handles continuous temperatures up to 150°C. PEN offers a middle ground, withstanding up to 180°C. If your design faces high thermal loads, polyimide provides the best protection.

| Material | Max Continuous Temp (°C) | Short-Term Max (°C) |

|---|---|---|

| Polyimide | 260 | 400 |

| PET | 150 | 180 |

| PEN | 180 | 200 |

Polyimide flex pcb thickness options allow you to maintain both flexibility and heat resistance in demanding applications.

Electrical Performance

Electrical performance depends on the dielectric constant and insulation properties. Polyimide and PET both offer stable electrical insulation, but polyimide maintains performance at higher temperatures. PEN provides a slightly lower dielectric constant, which benefits high-frequency circuits. PTFE and LCP, though less common, deliver even better electrical properties for specialised uses.

| Material | Dielectric Constant (1 MHz) | Insulation Quality | High-Frequency Suitability |

|---|---|---|---|

| Polyimide | 3.5 | Excellent | Good |

| PET | 3.2 | Good | Moderate |

| PEN | 3.0 | Good | Good |

You should select the material that matches your circuit's frequency and insulation requirements.

Cost Analysis

Cost often drives your material choice, especially for large-scale production. PET material pcb offers the lowest cost, making it attractive for consumer electronics. Polyimide costs more due to its advanced properties and processing requirements. PEN sits between PET and polyimide in terms of price. PTFE and LCP command premium prices, suitable only for high-performance or niche applications.

| Material | Relative Cost | Typical Use Case |

|---|---|---|

| Polyimide | High | Aerospace, automotive, medical |

| PET | Low | Consumer electronics, keypads |

| PEN | Medium | Automotive sensors, displays |

You can reduce costs by choosing PET for less demanding applications, but you may need to invest in polyimide for reliability in harsh conditions.

Application Suitability

You must align your material choice with your application's demands. Polyimide excels in environments that require durability, flexibility, and heat resistance. PET suits high-volume, cost-sensitive products where moderate flexibility and thermal stability suffice. PEN works well for applications that need a balance between performance and price.

-

For wearable electronics:

- Polyimide offers high heat resistance and exceptional flexibility. You should choose it for wearables that require durability during movement.

- PET is more affordable, but less durable under repeated flexing. It fits less demanding wearable applications.

-

For automotive and industrial uses:

- Polyimide remains the preferred option due to its reliability and thermal stability.

- PEN provides a cost-effective alternative for moderate heat environments.

-

For consumer electronics:

- PET material pcb supports lightweight and compact designs at a low cost.

A thorough flex pcb material comparison helps you select the right substrate for your project. You should always consider the application's environment, required flexibility, and budget.

Flex PCB Material Comparison Table

| Property | Polyimide | PET | PEN |

|---|---|---|---|

| Thickness Range (μm) | 12.5 – 125 | 25 – 125 | 25 – 125 |

| Flexibility | Excellent | Good | Good |

| Thermal Stability | Up to 400°C (short) | Up to 150°C | Up to 180°C |

| Electrical Performance | Excellent | Good | Good |

| Cost | High | Low | Medium |

| Typical Applications | Aerospace, Medical | Consumer Electronics | Automotive Sensors |

You should use this table to compare the main properties side by side. This approach ensures you make informed decisions for your fpc design.

Choosing the Right FPC Material

Design Considerations

You must approach flex pcb design with a clear understanding of your application’s demands. When you select materials for high-flex circuits, durability should be your top priority. Thermal behaviour and cost-effectiveness also play vital roles in ensuring your product performs reliably.

Consider these essential factors for successful fpc selection:

- Choose materials that offer long-term durability, especially for circuits that bend frequently.

- Assess thermal stability to prevent failures in heat-sensitive environments.

- Evaluate cost to balance performance with budget constraints.

- Maximise conductor width in areas that experience repeated bending.

- Avoid plated through-hole (PTH) designs, coverlays, and non-flowing prepreg in transition zones to maintain flexibility.

- Select reinforcement materials based on the mechanical strength your application requires.

Tip: For wearable and IoT devices, flexible PCBs enable compact, lightweight designs and provide the adaptability needed for repeated movement. You should also consider conformal coatings to protect your circuits from environmental contaminants.

When to Use PET vs Polyimide or Alternatives

You need to match the material to your project’s requirements. Polyimide suits applications where you expect high mechanical stress, elevated temperatures, or exposure to harsh environments. Its superior thermal stability and resilience make it ideal for aerospace, automotive, and advanced wearable devices.

PET material pcb offers a cost-effective solution for consumer electronics and products that do not face extreme conditions. You should choose PET when you need good flexibility and electrical insulation at a lower price point. PEN provides a middle ground, balancing cost and moderate thermal resistance, which works well for automotive sensors and displays.

The table below helps you decide which material fits your needs:

| Application Type | Recommended Material | Key Benefit |

|---|---|---|

| High-flex, harsh environment | Polyimide | Maximum durability, heat resistance |

| Cost-sensitive, moderate flex | PET | Affordability, good flexibility |

| Moderate heat, balanced cost | PEN | Thermal stability, reasonable price |

Note: Always align your material choice with the specific requirements of your flex pcb design. This approach ensures reliability and longevity for your final product.

You see clear differences between PET, polyimide, and other flexible PCB materials. PET offers low cost and good flexibility, while polyimide provides superior thermal stability and a wider thickness range. PEN sits between these options. To select the best fpc material, follow these steps:

- Assess your application’s needs, including flexibility and environment.

- Work with your design team to optimise layout and bend radius.

- Choose materials based on flexibility and thermal stability.

- Prioritise reliability and durability for demanding conditions.

- Use quality assurance to confirm performance.

Balance performance and cost to achieve the best results for your project.

FAQ

What is the main difference between PET and polyimide in flexible printed circuit board design?

You will notice PET offers lower cost and good flexibility, while polyimide provides higher thermal stability and durability. You should select PET for consumer devices and polyimide for demanding environments.

Can you use flexible printed circuits in high-temperature applications?

You can use flexible printed circuits in high-temperature settings if you choose polyimide or similar materials. PET does not withstand extreme heat, so you should avoid it for such applications.

How do you select the right fpc thickness for your project?

You should base your fpc thickness on the required flexibility and mechanical strength. Thinner materials allow tighter bends, but thicker options provide better durability for repeated use.

Are PET-based flexible PCBs suitable for automotive electronics?

You can use PET-based flexible PCBs in automotive electronics where moderate heat and flexibility are needed. For high-temperature or critical systems, you should consider polyimide instead.

What are the main benefits of using flexible printed circuit board technology?

You gain space savings, reduced weight, and improved reliability with flexible printed circuit board technology. This approach supports compact designs and enables circuits to fit into complex product shapes.

2025-11-10

2025-11-10

BEST

BEST

.png)

.png)

.png)

.png)

.png)