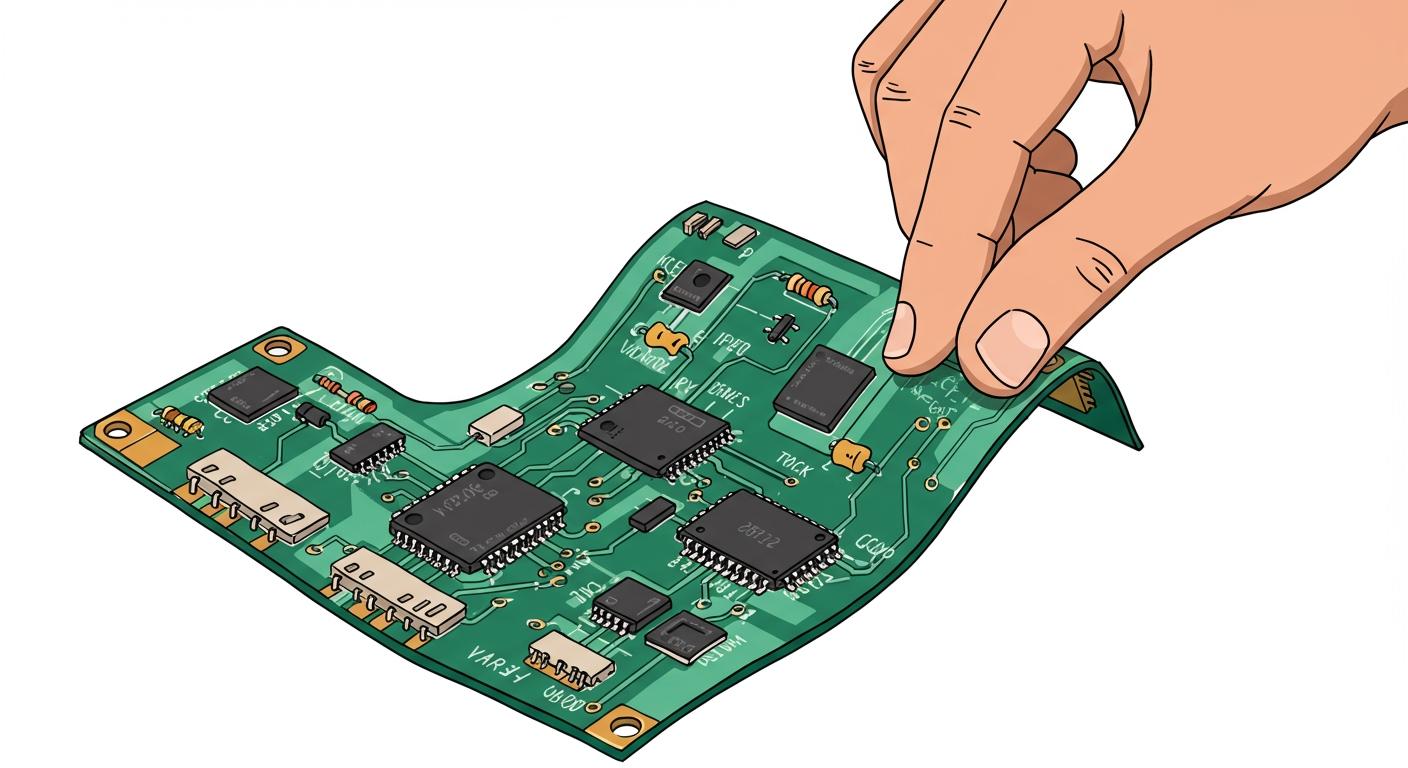

When you use flexible circuit components, you notice many key parts. These parts help flexible printed circuit boards work well. Substrate materials like polyimide and polyester give the boards their shape. Copper and other conductive materials make the electrical paths. Adhesives and coverlay keep the traces safe and insulated. You also find connectors, microcontrollers, converters, flash memory, antennas, batteries, and encapsulation materials. Flexible Circuits Components have mounted electronic parts. These parts help with processing, power, and communication.

- substrate materials

- conductive materials

- adhesives

- coverlay

- connectors

- microcontrollers

- converters

- flash memory

- antennas

- batteries

- encapsulation materials

- mounted electronic parts

Key Takeaways

- Flexible circuits use materials like polyimide and polyester. These materials give strength and flexibility. Pick the right substrate for your project’s needs.

- Copper is the main conductor in flexible circuits. It gives great conductivity and flexibility. You can use silver or carbon for special needs.

- Adhesives and coverlay protect circuits from damage. Choose the right adhesive for how much bending and heat your circuit will get.

- Connectors are important for linking flexible circuits to devices. Use the right connector to make strong and reliable connections.

- Stiffeners and surface finishes can make flexible circuits last longer. These parts help circuits work well in tough places.

Flexible Substrate Board Materials

Polyimide and Polyester

Polyimide and polyester are the main flexible substrate materials in flex circuits. Polyimide can handle high heat and is very strong. Polyester works well and costs less money. Both materials help flex circuit boards bend and fit into small spaces.

Here is a table that shows how they compare:

| Material | Thermal Stability | Chemical Resistance | Mechanical Properties | Electrical Insulation | Maximum Operating Temperature | Cost |

|---|---|---|---|---|---|---|

| Polyimide (PI) | Excellent | Excellent | Good | Good | ~260°C | Moderate |

| Polyester (PET) | Good | Good | Good | Good | ~150°C | Low |

Polyimide can take much more heat than polyester. You use polyimide in flex circuits for tough jobs and strong electronics. Polyester is good for things like gadgets and medical tools where price is important.

Role

Flexible substrate materials help flex circuit boards work well and last long. Polyimide gives great heat protection and is very strong. You can use it when you need to bend the board a lot or use it in hard places. Polyester keeps its shape and saves money. Both materials let flex circuits bend and twist, so they are good for wearable electronics and medical devices.

- Polyimide protects against heat and chemicals.

- Polyester is good for cheap and simple designs.

- Both materials keep circuits safe from water and damage.

- Flex circuits with these substrates send signals well.

You can pick the right substrate for your design. Polyimide is best for hot and tough jobs. Polyester is good for everyday electronics that do not need to be super strong.

Multilayer Structures

Multi-layered flexible circuits have more than one layer of flexible substrate materials. This helps you make small and strong flex circuit boards. These structures let you add more wires and features without making the board bigger.

Advantages of multilayer structures:

- You can fit more parts in a small space.

- Signals stay clear and steady.

- You get more ways to design tricky circuits.

- The board lasts longer and works better.

Disadvantages of multilayer structures:

- They cost more to make.

- The design and building are harder.

- It is tough to fix or change them.

You can use multilayer designs to make advanced flex circuits for hard jobs. These structures help you put more features in small devices, but you must plan well and watch the cost.

Conductive Materials in Flex Circuits

Copper Traces

Copper is used the most in flex circuits. Copper traces make the main paths for electricity. These paths connect all the parts together. Copper is good because it bends without breaking. It gives strong connections and moves signals fast. Copper also does not rust easily. This helps flex circuits last longer in hard places.

Other Conductors

Sometimes, you need other materials for special uses. You might use silver, carbon, or copper-nickel alloys. These are helpful if copper is too stiff or costs too much. For example, flexible silver shielding like DuPont CB028 uses a special ink. This ink can bend more than copper can. You use it when you need extra flexibility. Tatsuta shielding film works well on silver and has no adhesive. You pick these when copper shielding is too hard for your design.

- Silver shielding bends more for moving parts.

- Carbon traces are cheaper and work in simple circuits.

- Copper-nickel alloys handle heat and wear in tough places.

- Conductive inks let you print circuits on many surfaces.

Conductivity

You want your flex circuits to move signals fast and safely. Copper gives the best conductivity and bends well. That is why copper is in most flex circuits. Silver and carbon have their own special uses. Silver carries electricity almost as well as copper and bends more. Carbon does not carry electricity as well, but it is cheaper. It works for circuits that do not need much power. Copper-nickel alloys are not as good at carrying electricity. But they are stronger and handle heat better.

Tip: Pick your conductor based on what your circuit needs. Think about cost, how much it bends, and how much power it uses.

You can use different conductors in one flex circuit. This helps you get good performance and save money. When you design flex circuits, think about what each part does. Choose the material that works best.

Adhesives and Coverlay About FPCB

Adhesive Types

Adhesives help hold the layers of flexible circuits together. Picking the right adhesive makes your circuit strong and dependable. There are two main types you will see:

- Acrylic adhesives are good when your circuit needs to bend. They stay soft and flexible. But they can get weak if it gets too hot. In hot places, acrylic adhesives might let the layers come apart. Flame retardants can make them even less strong.

- Epoxy adhesives stick parts together very tightly. They work well when it is hot and do not stretch much. You use epoxy adhesives for circuits with many layers that need to stay together. But they are stiff and not good for circuits that bend a lot.

When you choose an adhesive, think about how much your circuit will bend and how hot it will get.

Coverlay Materials

Coverlay protects your circuit and keeps it insulated. You can pick from different coverlay materials. Each one has special features. Here is a table to help you compare:

| Material | Properties |

|---|---|

| Polyimide coverlay | Most common, great at handling heat and chemicals, very flexible, good for tough places. |

| Polyester coverlay | Cheaper, pretty flexible and insulates well, not as good with heat as polyimide. |

| Acrylic | Sticks well, works at medium temperatures, bonds nicely with polyimide. |

| Silicone | Super flexible, best for circuits that bend a lot, better for cooler places. |

| Liquid Crystal Polymer | Handles heat well, keeps signals clear, best for important and high-speed circuits. |

Polyimide coverlay is used a lot because it is strong and bends easily. Polyester coverlay is good if you want to save money and do not need much heat protection. You can pick coverlay materials that fit your circuit’s needs for bending, insulation, and safety.

Protection

Coverlay and adhesives work together to keep your circuit safe. The coverlay wraps around your circuit and gives it insulation. It stops problems during the lamination process. Adhesives keep all the layers stuck together, even when you bend or twist the board. This helps your circuit last longer and work better.

Note: If your circuit goes in hot or wet places, you need coverlay and adhesives that can handle these problems. High heat can make the coverlay crack or peel off. Wetness can sneak in and make copper traces rust or short out. Always pick materials that protect your circuit from these troubles.

Coverlay is very important for how long your circuit lasts and how well it works. Polyimide coverlay gives the best protection in tough places. Polyester coverlay is good for simple and cheap designs. When you pick coverlay materials, think about where and how you will use your circuit. The right choice keeps your circuit safe, strong, and working well.

Electronic Components and Connectors

Flexible printed circuit boards have many electronic parts. You see these parts on single-sided and double-sided boards. Each part does something important in flexible electronics. It is good to know how these parts work together. This helps make strong electrical connections.

SMT and Through-Hole

You can put electronic parts on flex circuits in two ways. Surface-mount technology (SMT) puts small parts on top of the board. This way saves space and works well for gadgets. Through-hole mounting pushes part leads through holes in the board. This way is stronger for tough jobs or machines.

- SMT is quick and fits lots of parts in small spaces.

- Through-hole mounting is better when the board shakes or gets hit.

- Many boards use both ways together. This gives you the good parts of each method.

Tip: Use SMT for small, light designs. Use through-hole for parts that need to be tough.

Passive and Active Parts

Flex circuits have passive and active parts. Passive parts do not need extra power. They help store, filter, or control energy. Active parts need power and can change signals.

| Feature | Active Components | Passive Components |

|---|---|---|

| Power Requirement | Needs outside power | No power needed |

| Amplification | Can make signals stronger | Cannot make signals stronger |

| Signal Control | Changes and controls signals | Cannot change signals |

| Main Function | Handles, switches, and controls power | Stores, filters, and controls power |

| Examples | Transistors, ICs, Op-Amps, diodes | Resistors, capacitors, inductors, transformers |

Passive parts like resistors, capacitors, and inductors help control voltage, store energy, and clean signals. Active parts like transistors, integrated circuits, and diodes handle signals, switch power, and control the circuit. Both types are needed for flex circuits to work well.

- Passive parts keep the circuit steady.

- Active parts help you control and handle signals.

- You need both types for strong and safe flexible printed circuit boards.

Connectors

Connectors link flex circuits to other boards or devices. Connectors help signals move safely and clearly. Picking the right connector makes your circuit last longer and work better.

| Connector Type | Advantages |

|---|---|

| ZIF Connectors | Cheap, used a lot, good for many jobs |

| Crimped Contacts | Easy to use, no hard board needed, common method |

| Interposer Connectors | Good for lots of pins, works well with shaking and bumps |

ZIF connectors are popular because they cost less and are easy to use. Crimped contacts let you connect without a hard board. Interposer connectors are great when you need lots of connections and face tough conditions.

- Good connectors make circuits last longer and work better.

- They help your circuit handle heat and movement.

- You see connectors in fast and tough jobs, like space and robots.

Note: Put connectors in smart places to stop signal loss and stress. The right connector keeps your flexible printed circuit boards working in hard places.

Connectors are on single-sided and double-sided flexible circuit boards. They help you build flexible electronics that bend and fit in small spaces. Flex circuits use new connectors for things like 6G antennas and brain-computer links. These connectors keep signals clear, even after lots of bending.

Flexible printed circuit boards use many electronic parts and connectors. You need to pick the best parts for your design. This helps you make flex circuits that last longer and work better in many devices.

Additional Flexible Circuit Components

Flexible circuits have more than just layers and traces. They also have extra parts that help them work better. These parts make flexible circuits last longer. They help the circuits work in hard places.

Stiffeners

Stiffeners give flexible circuit boards extra support. You use stiffeners to keep connectors in place. They protect solder joints from breaking. Stiffeners help with building the board by machines. They also make it easier to hold the board during making.

Here is a table that shows stiffener materials and what they do:

| Material Type | Properties | Use Case |

|---|---|---|

| Polyimide | Light, bends easily, handles heat | Gold finger support, wearable devices |

| FR4 (Fiberglass Epoxy) | Strong, can be soldered, not expensive | Holds parts, helps with machine building |

| Aluminum | Hard, helps with heat | Used in hot or stressed places |

| Plastic (PET) | Can be shaped, medium strength | Cheap designs, light support |

You find stiffeners in hdi flexible pcbs and rigid-flex pcbs. These boards need extra strength for connectors or heavy parts.

Tip: Put stiffeners under connectors or big chips. This stops bending and cracking.

Surface Finishes

Surface finishes protect copper traces on flexible circuits. They stop rust and help with soldering. The right finish keeps your circuit working after many bends.

- Hard gold: Good for moving parts, stops rust.

- Soft gold: Used for wire bonding, keeps connections clean.

- Immersion silver: Helps with soldering, keeps surface flat.

- Lead-free solder: Good for soldering, safe for nature.

- OSP: Keeps soldering easy, keeps surface smooth.

- White tin: Helps with soldering, keeps surface flat.

You see these finishes in hdi flexible pcbs when signal quality is important. A good finish helps your board last longer and keeps signals strong.

Optional Elements

You can add other things to your flexible circuit for special needs. These extra parts make your board easier to build and use.

| Optional Element | Benefit |

|---|---|

| Rigidizing connector sections | Stops stress from repeated use |

| Flat surfaces for SMT pads | Makes placing small parts easier |

| Localized bend constraints | Controls bending in some areas |

| Stiffeners | Adds strength and helps with heat |

Adding these parts can save money and make building faster. They also make your circuit stronger. You get better results when you pick the right parts for your design.

Note: Tests like bend cycle and peel strength checks show how well your circuit handles stress. Always test your design before making lots of boards.

Flexible circuits with these extra parts work better in many devices. You can design hdi flexible pcbs and rigid-flex pcbs that last longer and work well, even in hard jobs.

You have learned that each part changes how flexible circuits work. Picking good materials, connectors, and finishes helps your design last longer. It also makes your circuit work better. The table below shows why each part is important:

| Component Type | Importance | Key Takeaway |

|---|---|---|

| Material Selection | Changes strength, bending, and heat protection | Choose the right material for your project |

| Multi-layer Design | Helps make small, fast, and complex circuits | Makes circuits work better and stay strong |

| Rigid/Flexible Parts | Mixes support with bending ability | Saves space and makes circuits last longer |

When you pick parts, check their quality and price. Also look at what the industry says is best. Your choices matter for every flexible circuit you make.

2025-10-15

2025-10-15

BEST

BEST

.png)

.png)

.png)

.png)

.png)