When starting an electronics prototyping project, you have to make a tough decision: should you use a breadboard, perfboard, or PCB? Imagine building a simple circuit to test an idea. It’s important to consider how easy it will be to make changes during the electronics prototyping process. You also need to think about the durability of your project and how much you’re willing to spend. Here’s a comparison table to help you decide between breadboards and perfboards:

|

Feature |

Breadboard |

Perfboard |

|---|---|---|

|

Soldering Needed |

No |

Yes |

|

Reusability |

High |

Low |

|

Mechanical Strength |

Low |

High |

|

Cost |

Lower (if reused) |

Moderate |

Breadboards allow quick changes and can be reused multiple times, making them ideal for early stages of electronics prototyping. Perfboards offer greater mechanical strength and stability, better suited for more permanent projects. Choose the option that fits your skill level and whether your project is temporary or long-term.

Key Takeaways

- Breadboards help you build circuits quickly. You do not need soldering. They are great for beginners. They work well for fast tests.

- Perfboards need soldering to connect parts. They make circuits stronger. These circuits last longer. Perfboards are good for projects that stay for a while.

- PCBs give the best and most reliable results. They can handle complex designs. PCBs last for many years. They are best for finished products.

- Pick your prototyping method by your skill level. Think about how hard your project is. Consider your budget. Decide if your build is temporary or permanent.

- Start with breadboards to learn and test. Move to perfboards or PCBs when your project gets bigger. Use them when you need more strength.

Electronics Prototyping Platforms

Breadboard Overview

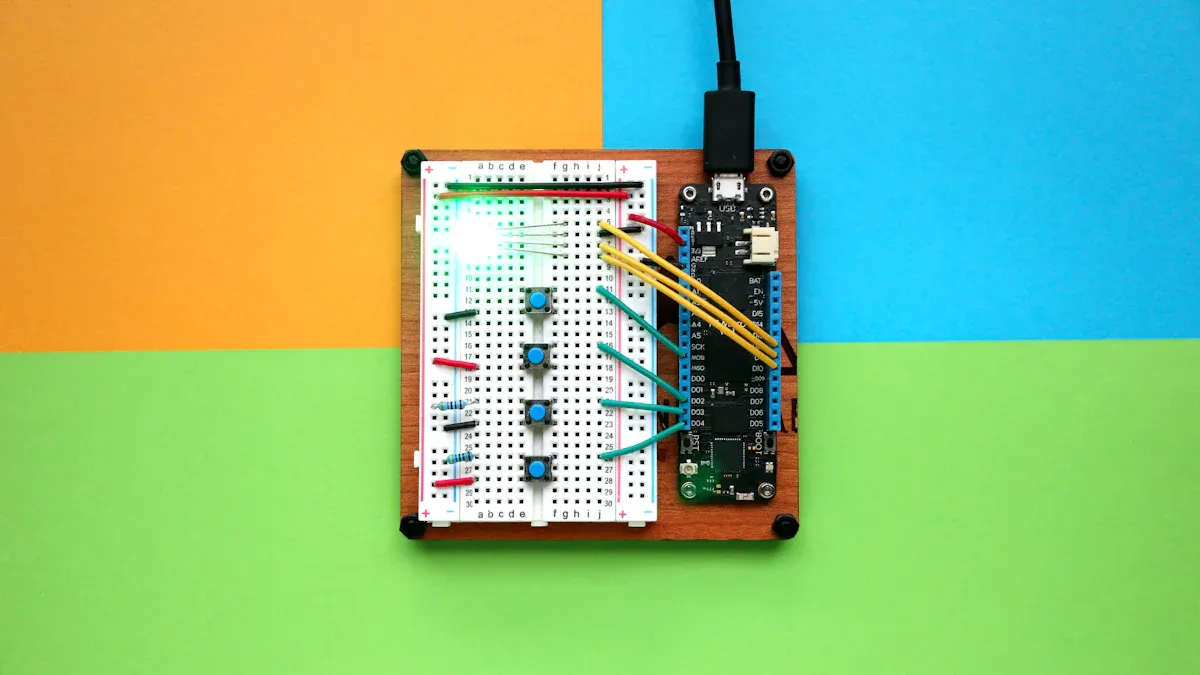

A breadboard is a very common tool for electronics prototyping. It looks like a plastic board with lots of tiny holes. Metal clips under the holes hold parts in place. You do not need to use solder with a breadboard. You can easily add or remove parts. This makes it great for testing new ideas. You can use the same breadboard for many projects. But, breadboards do not hold parts very tightly. They work best for circuits that use little power. If you want to build a simple circuit or learn how to connect things, a breadboard is a good pick.

Perfboard Overview

A perfboard gives your electronics prototyping more strength. It is made from fiberglass and has a grid of holes. Each hole has a copper ring around it. You must solder each part to the board. This makes your circuit last longer and stay together. Each hole is separate, so you can make your own design. This helps you build custom circuits for projects that need to last. Perfboards take more time to put together. You also need to know how to solder. If you want a circuit that will not break and you have extra time, a perfboard is a good choice.

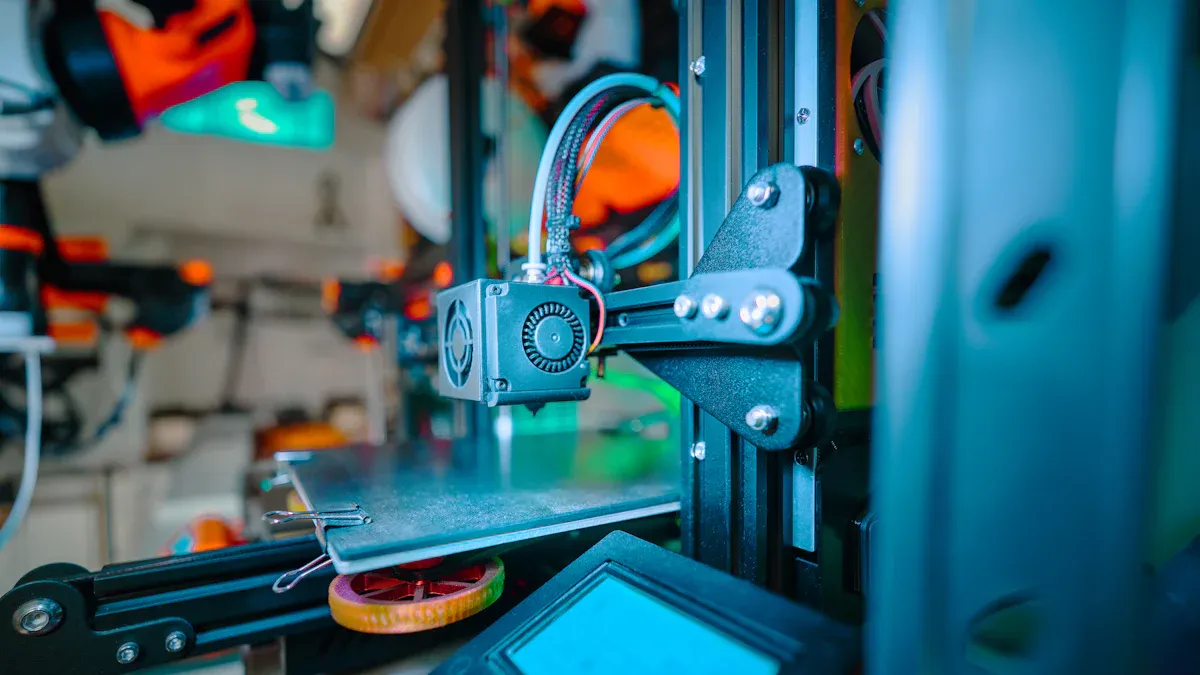

PCB Overview

A pcb, or printed circuit board, is the most advanced platform for electronics prototyping. Manufacturers make pcbs with copper lines that connect parts in a set pattern. You must solder parts onto the board. This makes the circuit strong and dependable. A pcb looks neat and supports hard designs. You can use a pcb for fast, packed, or permanent projects. Making a pcb takes more time and costs more money. But it gives you the best results for finished products. If you want your electronics prototyping to look and work like a real device, pick a printed circuit board.

Tip: Use the table below to compare the main features of each platform.

|

Feature |

Breadboard |

Perfboard |

PCB (Printed Circuit Board) |

|---|---|---|---|

|

Construction |

Fiberglass board with copper-plated holes; soldering required |

Fiberglass board with printed copper traces; soldering required |

|

|

Intended Use |

Temporary, quick prototyping |

Semi-permanent prototypes |

Permanent, reliable circuits |

|

Connectivity |

Metal clips connect groups of holes |

Manual wiring for each hole |

Pre-designed copper traces |

|

Mechanical Stability |

Least secure |

More stable |

Most stable |

|

Ease of Use |

Fastest; no soldering |

Slower; soldering needed |

Fast for assembly; soldering needed |

|

Reconfigurability |

Easy to change |

Difficult to rework |

Some tweaks possible |

|

Appearance |

Simple, color-coded |

Grid of holes |

Professional finish |

|

Typical Applications |

Early testing, learning |

Custom layouts, small projects |

Final products, advanced prototypes |

Rapid Prototyping: Breadboard vs Perfboard

Breadboard Features

When you start rapid prototyping, a breadboard gives you speed and flexibility. You do not need to solder any parts. You simply push wires and components into the holes. This makes breadboard prototyping perfect for testing ideas quickly. You can build a simple circuit in about 10 to 20 minutes, depending on how many parts you use. If you make a mistake, you can pull out a wire and try again. This saves you time and helps you learn faster.

Breadboards are highly reusable. You can use the same breadboard for many different projects. You can remove and replace parts without damaging them. This makes breadboards ideal for temporary circuits and for learning how to connect different parts. If you want to try new designs or fix errors, you can do it easily with a breadboard.

Tip: Breadboards work best for low-power circuits. If you use high power, the connections may become loose or overheat.

Perfboard Features

Perfboards give you more stability for your circuit, but they take more time to assemble. You must solder each part to the board. This step makes the connections strong and permanent. However, if you want to change your design, you need to desolder the parts, which can be hard and may damage them.

Perfboards are less reusable than breadboards. Once you solder a component, it is difficult to remove it without harm. This makes perfboards better for semi-permanent or permanent builds. If you want your circuit to last longer and stay together, a perfboard is a good choice.

When you use a perfboard for rapid prototyping, you spend more time building the circuit. You need to plan your layout and solder each connection. This process can take much longer than using a breadboard. However, the finished circuit will be more stable and reliable.

|

Feature |

Breadboard |

Perfboard |

|---|---|---|

|

Assembly Time |

10–20 minutes |

Longer, due to soldering |

|

Soldering Needed |

No |

Yes |

|

Reusability |

High |

Low |

|

Stability |

Low |

High |

|

Best Use |

Temporary, quick testing |

Permanent, stable builds |

Rapid prototyping often starts with breadboard prototyping because it lets you test and change your circuit quickly. If you need a more stable build, you can move your design to a perfboard after you finish testing.

PCB in Prototyping

PCB Advantages

If you want your electronics project to be very reliable, choose a pcb. A pcb gives you strong soldered connections that last. Your circuit will not break if it gets bumped or moved. Breadboards use springs, and perfboards need you to solder each part. But a pcb is made by experts in a factory. The process makes neat copper lines and drilled holes. Every connection stays strong and works well.

You get many good things with a pcb:

- Soldered joints that do not shake loose or wear out.

- Professional look with thin copper lines and many layers.

- Very strong board, so wires do not come loose.

- Can handle special features like fast signals and tricky designs.

A printed circuit board can have up to 32 layers. This lets you build small, powerful circuits. A pcb is the best pick for projects that need lots of power, speed, or tough designs.

Note: Breadboards and perfboards can have connection problems. A pcb does not have these issues because it is made with care and strong materials.

When to Use a PCB

Pick a pcb when your project needs to last a long time or work well in small spaces. If you want your circuit to work outside or in tough places, a pcb is a smart choice. Projects in robots, car sensors, planes, and medical tools use pcbs. These projects need to work even if they shake, get hot, or face stress.

Flex PCBs are a special kind of pcb. They use bendable stuff like polyimide. These boards can twist and bend. They are great for devices with weird shapes or tight spaces. Flex PCBs save room, make building easier, and handle shaking better than stiff boards. People in the US use flex PCBs in phones, drones, and smart gadgets. If your project needs to fit in a small or moving device, think about using a flex pcb.

Use a pcb for:

- Products that need to last and look good.

- Circuits with lots of parts or layers.

- Projects that need to work well or have special features.

- Small or bendy devices that use flex PCBs.

A pcb helps you turn your test circuit into a real product. You can trust your circuit to work and last.

Pros and Cons

Breadboard Pros and Cons

A breadboard lets you build circuits fast. You do not need to solder parts. You can change your design quickly. Many beginners like breadboards because they are easy to use. You can use the same parts for many projects.

|

Pros |

Cons |

|---|---|

|

Not stable for long-term use |

|

|

Beginner-friendly and reusable |

Unreliable connections over time |

|

Fast for rapid prototyping |

Not for high-frequency or high-current work |

|

Easy to change and debug |

Limited to simple, low-power circuits |

Breadboards are great for learning and early tests. Sometimes, the wires get loose. The circuit may not work well for big or permanent projects.

Perfboard Pros and Cons

Perfboards are stronger and more stable than breadboards. You must solder each part to the board. This makes your circuit last longer. Perfboards are good for small, permanent projects and custom designs.

|

Pros |

Cons |

|---|---|

|

Good for permanent or semi-permanent builds |

Hard to change or debug after assembly |

|

Supports custom layouts |

Less reusable than breadboards |

|

Handles more complex circuits |

Takes more time to assemble |

You need to plan your wiring before you start. Soldering can be hard, so use tweezers and a magnifying glass for small parts. If you want a circuit that lasts, perfboard is a good pick.

PCB Pros and Cons

A pcb gives you the most professional and strong results. You get solid, lasting connections and a neat look. Many engineers use pcbs for finished products or advanced projects.

|

Pros |

Cons |

|---|---|

|

Higher cost and longer lead time |

|

|

Professional look and compact design |

Hard to modify after fabrication |

|

Supports complex and high-speed circuits |

Requires design skills and planning |

|

Almost no component limitations |

PCBs give you the best performance and support for advanced features. You may have to wait for it to be made and pay more. But you get a finished product that works well and lasts. Flex PCBs help fit circuits into small or moving devices, so they are popular in modern electronics.

Project Considerations

Ease of Use

When you test circuits, pick a platform that fits your skills. Breadboard is great for beginners. You do not need to solder parts. You can build and change your circuit fast. This helps you learn and fix problems easily. Perfboards need you to solder, so they take more time and practice. Custom PCBs need you to use design software. You also must know how they are made. The table below shows how easy each platform is to use:

|

Factor |

Breadboard |

Perfboard |

Custom Proto PCB |

|---|---|---|---|

|

Ease of Use |

Very easy |

Moderate |

Less easy |

|

Connectivity |

Solderless |

Soldered |

Soldered/Surface-mount |

|

Durability |

Low |

Moderate |

High |

|

Complexity Suitability |

Simple |

Moderate |

Complex |

|

Cost |

Low |

Moderate |

Higher |

2025-08-26

2025-08-26

BEST

BEST

.png)

.png)

.png)

.png)

.png)