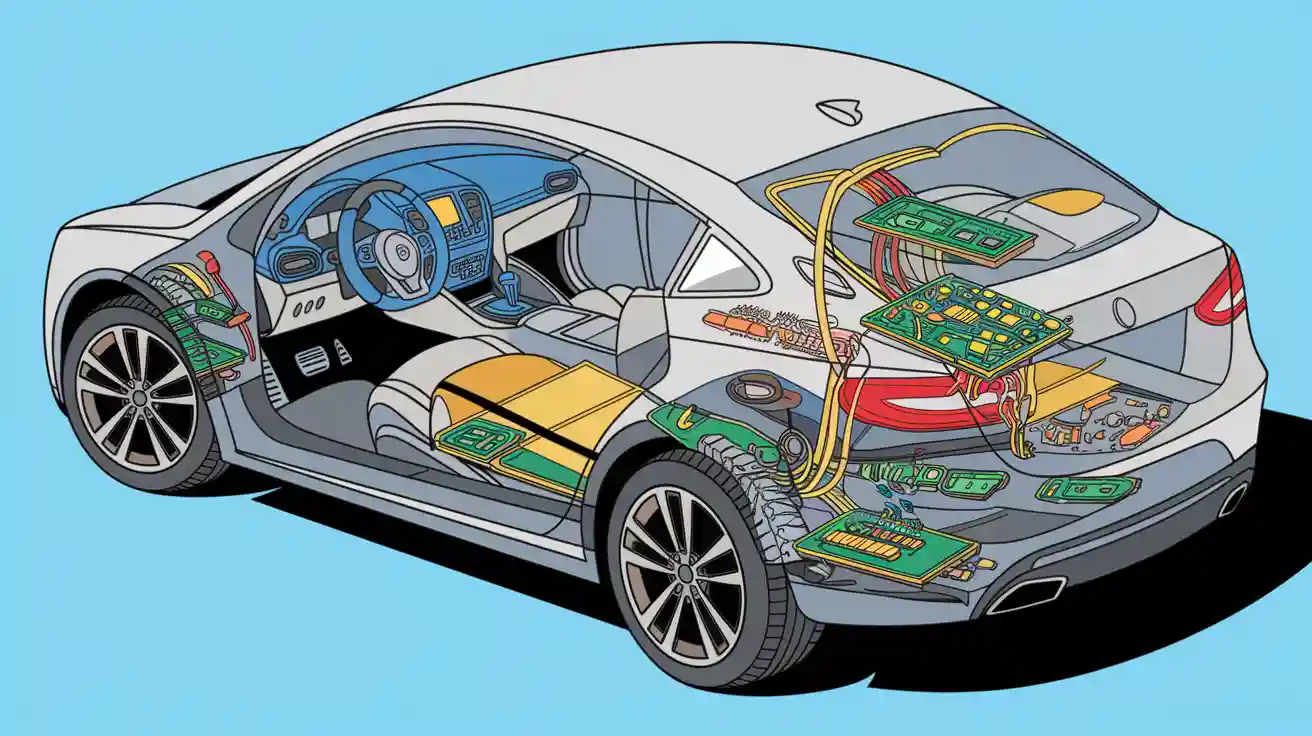

You see flexible printed circuits in the car’s display screen, car armrest screen, battery management systems, sensors, camera modules, infotainment systems, lighting, and connectivity modules. FPC in the car supports lightweight design, flexibility, and improved safety. You notice these features most in electric and smart vehicles.

If you want to learn more or discuss how FPC can improve your car’s electronics, reach out for details or collaboration.

Key Takeaways

- FPCs enhance the design of display screens in cars, allowing for lightweight, durable, and flexible screens that fit into tight spaces.

- Battery management systems benefit from FPCs by improving reliability and efficiency, leading to better battery performance and longer life.

- FPCs support the miniaturization of sensors and cameras, resulting in smaller, lighter devices that improve safety and convenience in vehicles.

- The use of FPCs in infotainment and communication modules ensures high-speed transmission and reliable connections, enhancing the overall driving experience.

- FPC technology is crucial for the future of electric and smart vehicles, providing lightweight solutions that improve energy efficiency and support advanced features.

FPC in the Car: Key Applications

Display Screens

You see fpc in the car used in display screens every time you interact with your dashboard or infotainment system. Flexible printed circuits allow manufacturers to create screens that fit into tight spaces and unusual shapes. This technology supports touchscreens and digital displays, making them lighter and more durable than traditional PCBs.

| Technical Reason | Description |

|---|---|

| Spatial Optimization | FPCs can adapt to various shapes and sizes, allowing for a more compact and efficient layout in vehicles. |

| Weight Reduction | FPCs are lighter than traditional PCBs, contributing to overall vehicle weight reduction and improved fuel economy. |

| Increased Durability | FPCs absorb vibrations and maintain performance across a wide temperature range, enhancing durability. |

| Adaptability to Harsh Environments | FPC materials resist corrosion and humidity, making them suitable for extreme automotive conditions. |

You benefit from robust and flexible connectors in your screen. These connectors withstand harsh conditions, including heat and vibration. Manufacturers use automated soldering techniques, which speed up installation and improve consistency.

- FPC connectors are robust and flexible, making them capable of withstanding harsh environmental conditions, which is essential for automotive applications.

- The installation process is efficient due to straightforward soldering techniques that can be automated, enhancing manufacturing speed and consistency.

Car Armrest Screens

Car armrest screens have become a popular feature in modern vehicles. You notice these screens in luxury models and electric cars. Fpc in the car enables thinner and lighter circuits, which help reduce the overall weight and save space. This design flexibility lets engineers add features like haptic feedback and backlighting. You experience smoother integration of these screens into dashboards and armrests because fpc applications allow circuits to form into 3D shapes.

Car armrest screens also help lower production costs. Manufacturers use fewer materials and simplify assembly, which makes these screens more affordable for you. The flexibility of fpc in the car means you get more advanced features without sacrificing comfort or style.

Battery Management

You rely on battery management systems to keep your electric vehicle running smoothly. Fpc in the car plays a key role in these systems. Flexible printed circuits provide reliability and flexibility, which are essential for the demanding environment inside a car. You get better battery performance and longer life because fpc helps monitor and manage battery cells efficiently.

- FPCs provide flexibility and reliability, essential for the demanding environments in vehicles.

- They enhance the efficiency of battery management systems, ensuring optimal performance and longevity of electric vehicle batteries.

- The integration of FPCs is crucial for monitoring and managing battery performance as the automotive industry shifts towards electrification.

- FPCs offer low wiring complexity compared to decentralized systems with discrete wires, simplifying the design of battery packs.

- They are indispensable in modern Battery Management System (BMS) designs, meeting the growing demand for efficient energy storage solutions.

You benefit from improved signal integrity and reduced resistance in your battery system. High-quality copper traces in fpc ensure low resistance paths, which help with thermal management and efficiency. The compact design of fpc in the car streamlines manufacturing and reduces the risk of miswiring. You get a safer and more reliable battery system because fpc minimizes errors and withstands high temperatures, vibrations, and moisture.

- Improved Signal Integrity: FPCs provide consistent and controlled impedance paths for data and power signals, enhancing overall system performance.

- Reduced Resistance: High-quality copper traces ensure low resistance paths, contributing to better thermal management and efficiency.

- Compact Design: FPCs streamline manufacturing processes and reduce the risk of miswiring, leading to a more reliable battery management system.

- Error Prevention: The continuous piece design of FPCs minimizes the chance of miswiring, improving reliability and reducing assembly time.

- Enhanced Durability: FPCs are designed to withstand high temperatures, vibrations, and exposure to moisture, improving the long-term durability of battery systems.

Sensors and Cameras

You depend on sensors and cameras for safety and convenience in your car. Fpc in the car supports miniaturization and reliability in these components. Flexible printed circuits reduce the number of parts, which means smaller and lighter devices with fewer points of failure. You get reliable performance from sensors and cameras that fit into limited spaces.

| Type of Automotive Component | Application of FPC Technology | Advantages of FPC |

|---|---|---|

| Sensors | Used in various automotive sensors | Reduces weight and complexity |

| Camera Modules | Integrated into vehicle display modules | Cost-effective and lightweight |

| Power Batteries | Enhances connectivity and efficiency | Optimizes space and reduces wiring |

| Lights | Supports advanced lighting systems | Lightweight and flexible design |

Fpc technology allows for sophisticated circuit patterns on a flexible substrate. You see this in advanced driver-assistance systems, parking cameras, and blind-spot sensors. The flexibility and compact integration of fpc in the car make it possible to add more features without increasing size or weight.

You experience safer driving and better convenience because fpc applications in sensors and cameras improve reliability and performance. Manufacturers use fpc to create devices that withstand vibration, heat, and moisture, which are common in automotive environments.

Tip: If you want to learn more about how fpc in the car improves your driving experience or have questions about rigid-flex PCB solutions, you can contact our team for details or collaboration.

Infotainment and Connectivity

Audio and Navigation

You interact with multimedia entertainment systems every time you drive your car. Flexible printed circuits (FPCs) play a key role in these in-vehicle systems. You notice how multimedia and navigation systems fit into tight spaces and complex shapes. FPCs make this possible because they bend and adapt to the car’s interior. You get a better user experience with lightweight and thin circuits that help reduce the car’s weight and improve energy efficiency.

FPCs also support high-speed transmission, which is important for real-time navigation and multimedia playback. You enjoy clear audio and fast map updates because FPCs provide reliable connections. The circuits resist bending, high temperatures, moisture, and corrosion, so your navigation systems work well in harsh conditions.

Tip: You can rely on FPCs for stable operation and fewer failures in your multimedia and navigation systems. This means you experience safer and more enjoyable journeys.

Here is how FPCs benefit audio and navigation modules:

- Lightweight and thin design improves energy efficiency.

- Bendability adapts to complex car interiors.

- High-speed transmission supports real-time navigation and multimedia.

- High reliability reduces the risk of failure and improves safety.

| Benefit | Description |

|---|---|

| Flexibility | FPC adapts to complex spatial structures inside vehicles. |

| Lightweight Design | Reduces overall vehicle weight. |

| High-Speed Transmission | Meets requirements for fast signal transmission. |

| High Reliability | Enhances vehicle safety. |

| Environmental Adaptability | Ensures stable operation in harsh conditions. |

Communication Modules

You depend on communication modules for a connected driving experience. FPCs improve the integration of these modules in modern cars. You benefit from enhanced signal integrity and high-frequency performance, which are essential for connecting sensors and computing units. This is especially important in advanced vehicles, such as self-driving trucks.

FPCs save space by replacing multiple wires and connectors with a single flexible circuit. You experience fewer wiring issues and easier installation. The flexibility of FPCs allows them to endure bending and twisting, which is common in cars that face constant vibration.

- FPCs enhance signal integrity for communication between in-vehicle systems.

- The space-saving design supports the growing number of electronics in modern cars.

- You get reliable performance even in challenging environments.

You notice that FPCs make your multimedia and communication modules more efficient and durable. This technology helps you enjoy a seamless driving experience with fewer interruptions.

Automotive Lighting

LED Headlights

You rely on LED headlights for clear vision and safety during night driving. Flexible printed circuits (FPCs) play a big part in making these headlights efficient and reliable. FPCs handle heat, vibration, and moisture, which are common in the front of your car. Advanced materials in FPCs give thermal stability and prevent cracking or delamination. This means your headlights last longer and work better in tough conditions.

FPCs also fit into the unique shapes of modern headlights. You see sleek designs because FPCs bend and adapt to tight spaces. This flexibility helps engineers create headlights that look good and perform well. Robust connectors and high-performance drivers in FPCs keep your lighting system efficient.

- FPCs withstand heat, vibration, and moisture.

- They provide thermal stability and resist cracking.

- Flexible designs allow for compact and stylish headlights.

- Reliable connectors and drivers support efficient lighting.

You get brighter, longer-lasting headlights that use less energy. FPCs make it possible for your car to have advanced lighting features without adding extra weight.

Interior Lighting

You notice how interior lighting in your car creates a comfortable and modern atmosphere. FPCs help designers add lights in places that were once hard to reach. Their flexibility lets you enjoy creative lighting patterns and smooth lines inside your vehicle.

FPCs make it easy to route circuits in tight spaces. This is important for features like ambient lighting, dashboard accents, and illuminated controls. Lightweight FPCs also help your car stay efficient by reducing overall weight.

| Reason for Adopting FPC | Description |

|---|---|

| Compact Routing | FPCs enable efficient routing in tight spaces, essential for modern automotive designs. |

| Thermal Management | They assist in managing heat in confined areas, crucial for safety and performance. |

| Lightweight and Flexible | Their design allows for innovative and adaptable interior layouts. |

You benefit from lighting that fits perfectly into the car’s design. FPCs allow for bending and folding, so manufacturers can place lights in unique spots. This technology supports both navigation systems and entertainment consoles, making your driving experience more enjoyable.

Tip: If you want to explore more about how FPCs improve your car’s lighting or have questions about rigid-flex PCB solutions, feel free to reach out for details or collaboration.

Advantages of FPC

Lightweight and Flexibility

You benefit from flexible printed circuits because they make your car lighter and more efficient. FPCs replace bulky wiring with thin, bendable circuits. This change helps manufacturers fit electronics into tight spaces and unusual shapes. You see this advantage in electric vehicles, where every gram counts for range and performance.

- The global market for passenger car FPCs reached about USD 1.5 billion in 2023 and could grow to USD 3.2 billion by 2032. This growth shows how much automakers value lightweight and flexible solutions.

- FPCs help reduce wiring complexity and lower vehicle weight. You get better fuel efficiency and lower emissions.

- The demand for high-density, lightweight circuitry has surged as electric vehicles become more popular.

- FPCs streamline assembly steps, so manufacturers can integrate electronic systems faster.

| Industry | Impact of Weight Reduction |

|---|---|

| Automotive | Reduced vehicle weight, better fuel economy |

You notice that FPCs allow for creative designs and more features without adding extra bulk. This flexibility supports advanced screens, sensors, and lighting systems. Manufacturers use FPCs to improve space utilization and speed up production.

Tip: If you want to know how FPCs can make your vehicle lighter and more efficient, you can ask our team for details or collaboration.

Safety and Reliability

You rely on FPCs for enhancing safety and reliability in your vehicle’s electronics. Flexible circuits connect critical systems like infotainment, battery management, and advanced driver assistance. Their design allows for seamless integration into compact spaces, which improves both function and safety.

- FPC connectors play a key role in enhancing safety for infotainment and ADAS systems.

- New energy FPC designs protect batteries in electric and hybrid vehicles, ensuring safe and efficient operation.

- Automotive manufacturers use rigorous testing to guarantee reliability. These tests include temperature cycling, exposure to fluids, salt spray, and vibration.

| Testing Procedure | Description |

|---|---|

| Temperature Cycling Tests | Range from -40°C to +125°C over 1,000 cycles to ensure reliability. |

| Exposure to Automotive Fluids | Checks resistance to various fluids. |

| Salt Spray Testing | Assesses corrosion resistance. |

| Vibration Testing | Evaluates durability during vehicle operation. |

| Qualification Timeline | Testing can extend qualification by 18-24 months. |

You see FPCs used in battery protection circuit boards, which are vital for enhancing safety in electric vehicles. Manufacturers must meet strict industry standards, so you get reliable and safe electronics in your car.

Note: If you want to learn more about how FPCs improve reliability and safety, you can reach out for expert advice or collaboration.

Future Trends

Electric Vehicles

You see electric vehicles changing the way cars use flexible printed circuits. Over 63% of electric vehicles now rely on FPCs for battery management systems and infotainment modules. You notice how FPCs help cars achieve efficient energy management and improve energy efficiency. The automotive sector makes up 21% of the FPC market, and experts predict the overall FPC market will grow at a CAGR of 12.17% from 2025 to 2033.

- FPCs streamline wiring systems in electric cars.

- You benefit from reduced weight and better energy efficiency.

- Cars use FPCs to support advanced battery management and infotainment.

- You experience longer driving ranges and improved performance.

You see FPCs helping electric cars handle high power demands and maintain safety. These circuits resist heat and vibration, which keeps your driving experience reliable. You notice how manufacturers use FPCs to make cars lighter and more efficient. You get more features in your car without sacrificing energy efficiency.

Tip: You can explore how FPCs make electric cars smarter and more efficient. Reach out if you want to learn more or discuss collaboration opportunities.

Smart Car Innovations

You see smart cars leading the way in automotive technology. FPCs play a key role in supporting autonomous driving systems and intelligent cockpit systems. You notice how cars use high-density interconnect FPCs to enable advanced features like autonomous driving and real-time data processing.

| Advancement Type | Description |

|---|---|

| Rapid Adoption in Electric Vehicles (EVs) | FPCs streamline wiring systems and reduce weight, enhancing energy efficiency and vehicle performance. |

| High-Density Interconnect (HDI) FPCs | Innovations in design are driving advancements in smart automotive applications like autonomous driving. |

| Integration in ADAS | FPCs enhance performance and safety in systems reliant on real-time data for collision avoidance. |

You experience safer driving with smart cars that use FPCs in autonomous driving systems. These cars process data quickly and respond to road conditions in real time. You see FPCs supporting efficient energy management and energy efficiency in every part of the car. Smart cars use FPCs to connect sensors, cameras, and infotainment modules, making your driving experience smoother and more enjoyable.

- Smart cars rely on FPCs for autonomous driving and efficient energy management.

- You benefit from improved safety, energy efficiency, and advanced features.

- Cars use FPCs to support high-speed data transmission and reliable connections.

You notice how smart cars continue to evolve with FPC technology. You can expect more innovations in autonomous driving systems and energy efficiency. If you want to stay updated or discuss how FPCs shape the future of smart cars, you can contact our team for details or collaboration.

You see FPC and rigid-flex PCB in many parts of your car, such as display screens, battery systems, sensors, and lighting. These circuits offer lightweight design, strong safety, and flexible layouts.

- The use of FPC in electric and smart vehicles keeps growing.

- FPC connectors support new smart solutions and Industry 4.0 trends.

- The market for FPC in new energy vehicles is rising fast.

| Feature | FPC Benefits | Traditional PCB Benefits |

|---|---|---|

| Weight | Reduced size and weight | Heavier materials |

| Design Flexibility | Fits tight or irregular spaces | Limited shapes |

| Reliability | Fewer connection failures | More connection issues |

| Heat Dissipation | Good heat management | Often less efficient |

| Cost-effectiveness | Lower cost for small production | Higher cost for small runs |

You can expect FPC technology to shape the future of automotive electronics. Reach out if you want to learn more or discuss collaboration.

2025-09-11

2025-09-11

BEST

BEST

.png)

.png)

.png)

.png)

.png)