I am excited to share that BESTFPC has entered a cooperation agreement with a leading German solar manufacturer. This partnership brings together our expertise in multi-layer rigid-flex PCBs and their drive for innovation in solar technology. We will handle every stage, from design guidance and cost reduction to functional testing, batch production, soldering, and SMT assembly. I see this as a major step forward for both companies and the solar industry.

Key Takeaways

- BESTFPC's partnership with a German solar manufacturer aims to produce 200,000 high-quality multi-layer rigid-flex PCBs, enhancing solar technology.

- Collaboration fosters innovation, allowing both companies to share knowledge and improve product performance in the solar industry.

- Clear agreements on intellectual property ensure both parties feel secure, promoting trust and creativity in the partnership.

- This cooperation opens new market opportunities in Europe, helping BESTFPC expand its reach and adapt to local needs.

- The project highlights the importance of teamwork in driving advancements in renewable energy and encourages others to pursue similar collaborations.

Cooperation Agreement Overview

Parties and Roles

I see this cooperation agreement as a true partnership. BESTFPC brings years of experience in designing and manufacturing multi-layer rigid-flex PCBs. The German solar manufacturer leads in solar technology and innovation. Together, we combine technical strength and industry knowledge. I work closely with their engineering team to understand their needs. My team provides design guidance, cost analysis, and technical support. The German partner focuses on integrating our PCBs into their solar products. We both share responsibility for quality and performance.

I also notice the involvement of the German Solar Association. Their support helps us align with industry standards and best practices. This collaboration encourages open communication and shared goals. I believe this teamwork sets a strong foundation for success.

Agreement Scope

The cooperation agreement covers every step of the process. I guide the design of multi-layer rigid-flex PCBs to meet strict solar industry requirements. My team works to reduce costs without sacrificing quality. We perform functional testing to ensure each PCB meets performance standards. I oversee batch production, soldering, and SMT assembly. This full-service approach gives the German partner a complete solution.

Our objectives include:

- Delivering 200,000 high-quality multi-layer rigid-flex PCBs.

- Supporting the German partner’s product development and market expansion.

- Meeting agreed delivery timelines and maintaining consistent quality.

The agreement also includes research and development. I work with their engineers to improve PCB designs for future solar products. We set clear milestones and deadlines for each phase. I track progress and adjust plans as needed to stay on schedule.

I see this cooperation agreement as part of a larger trend in the solar industry. Many companies now form international partnerships to reach global goals. For example:

- The EU-Egypt Strategic Partnership in 2024 aims to boost renewable energy investment.

- The EU created a special commissioner for Mediterranean energy projects.

- The TeraMed Initiative targets 1 terawatt of renewable capacity by 2030, matching global climate goals.

These trends show that teamwork and innovation drive the solar industry forward. Our agreement fits well with these global efforts.

Key Terms

I pay special attention to intellectual property (IP) management in this cooperation agreement. We want to protect our ideas and ensure fair use of new technology. The agreement includes several important IP terms:

- Ownership and use of IP created or used during the project.

- Clear rules for who owns pre-existing IP.

- Specific guidelines for new IP developed together.

- Procedures for handling IP disputes and protecting confidential information.

- Confidentiality and non-disclosure requirements.

- Licensing terms, if needed.

I believe these terms help both sides feel secure. We can share ideas and work together without worry. This trust supports real innovation.

I see this cooperation agreement as a model for future projects. It covers technical, legal, and business needs. I encourage readers to reach out if they have questions about rigid-flex PCBs or want to explore similar collaborations. I am always ready to share my experience and help others succeed in the solar industry.

Partnership Significance

Strategic Value

I see this cooperation agreement as a turning point for BESTFPC. By working with a top German solar manufacturer, I can expand into new markets and strengthen our position as a technology leader. Here are some key advantages I notice:

- I can reach emerging markets in Southeast Asia and Eastern Europe.

- My team can offer more advanced products to meet different industry needs.

- I invest more in research and development, which leads to better PCB designs.

- I lead the way in quick-turn solutions for rigid-flex PCBs.

- I focus on sustainable manufacturing and care about the environment.

- My strong customer support helps build lasting relationships.

This partnership lets me learn from the German market and adapt quickly. I believe it also shows my commitment to quality and innovation.

Industry Impact

I believe this cooperation agreement will have a big impact on the solar industry. The large-scale production of multi-layer rigid-flex PCBs will help improve the supply chain for solar inverter components. This supports government efforts to expand renewable energy. As global demand for solar power grows, I see more need for advanced power electronics.

- Businesses can lower costs and improve their ESG ratings by using solar energy.

- The move to solar matches what consumers want—eco-friendly solutions.

- Germany’s goal of 65% renewable energy by 2030 increases demand for solar products.

- New rules make it easier for companies to start solar projects.

- More companies sign power purchase agreements to meet ESG goals.

- Higher feed-in tariffs and easier installation rules make solar more accessible.

- Better energy storage and grid connections help solar fit into the power system.

International partnerships like this one break down barriers and speed up innovation. Digital networks let me work with experts around the world in real time. This helps share new ideas faster and makes solar technology better for everyone.

I encourage readers to reach out if they have questions about rigid-flex PCBs or want to discuss new projects. Working together, we can drive the solar industry forward.

Production Details

PCB Specifications

I focus on using advanced materials and technologies for these multi-layer rigid-flex PCBs. Each board combines flexible and rigid layers to meet the demands of solar applications. Here is a quick overview of the main materials I use:

| Material Type | Properties | Usage |

|---|---|---|

| Polyimide | Flexible, high-temperature tolerance | Flexible layers |

| FR-4 | Rigid, durable, low-cost | Rigid layers |

| Copper Foil | Conductive, thin | Circuit traces and vias |

| Rogers | High-frequency performance, stable | High-performance rigid layers |

I also use several key technologies:

- HDI (High-Density Interconnect) for compact circuit layouts.

- Blind and buried vias to connect layers efficiently.

- Via-in-pad technology to increase density.

- Sequential lamination for precise multi-layer construction.

These features help me deliver PCBs that support high performance and reliability in solar products.

Manufacturing Scale

I manage the batch production of 200,000 multi-layer rigid-flex PCBs for this project. This large volume requires careful planning and efficient processes. My team uses automated assembly lines and strict scheduling to meet delivery timelines. I monitor each production stage to ensure consistency and minimize errors.

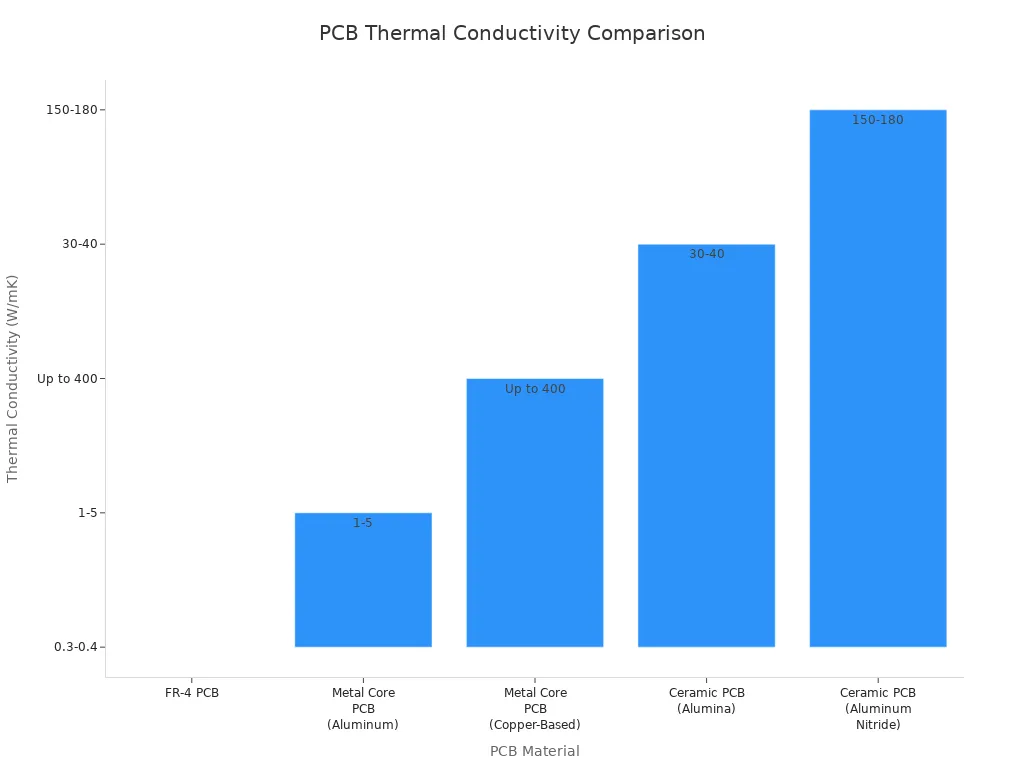

To compare our materials with industry standards, I look at thermal conductivity, which is important for heat management in solar electronics:

| PCB Material | Thermal Conductivity (W/mK) | Suitability for Heat Dissipation |

|---|---|---|

| FR-4 PCB | 0.3-0.4 | Low to medium heat dissipation needs |

| Metal Core PCB (Aluminum) | 1-5 | Moderate to high heat dissipation |

| Metal Core PCB (Copper-Based) | Up to 400 | Extreme thermal management |

| Ceramic PCB (Alumina) | 30-40 | Superior heat transfer for demanding apps |

| Ceramic PCB (Aluminum Nitride) | 150-180 | Top-tier performance for critical systems |

I select materials that balance cost, durability, and heat management, which is vital for solar industry needs.

Quality Standards

I take quality assurance seriously at every step. My process includes alignment checks, layer bonding tests, electrical performance evaluations, and flexibility assessments. These steps confirm that each PCB meets strict functional and structural requirements.

I follow international standards and certifications to guarantee quality and safety:

| Standard/Certification | Scope | Impact on PCB Quality Assurance |

|---|---|---|

| IPC-A-600 | PCB acceptability | Reduces defects, ensures design specs |

| ISO 9001 | Process optimization | Improves manufacturing, builds trust |

| RoHS | Hazardous substance limits | Ensures environmental compliance |

| UL | Safety and fire resistance | Confirms electrical and fire safety |

I also adopt greener processes, recycle materials, and reduce hazardous substances. My commitment to ISO 9001 and ISO 14001 ensures that I meet both quality and environmental standards. If you have questions about our production or want to discuss collaboration, I invite you to reach out. I am always ready to share more about our approach to rigid-flex PCB manufacturing.

Benefits and Future Prospects

Mutual Advantages

I see many mutual advantages in this cooperation agreement. My team gains access to advanced solar technology and new markets. The German partner benefits from my expertise in multi-layer rigid-flex PCBs and reliable production. We both share knowledge and improve our products. I learn from their experience in solar applications, while they get high-quality PCBs that boost their product performance.

I often look at other successful partnerships for inspiration. Here is a table with some examples and what I learn from them:

| Case Study | Key Lessons |

|---|---|

| Tesla’s Solar Microgrid in Puerto Rico | Resilience, energy independence, scalability |

| Noor Ouarzazate Solar Complex, Morocco | Using natural resources, energy export, technology mix |

| Bhadla Solar Park, India | Economies of scale, policy support, overcoming challenges |

These cases show that strong partnerships can lead to real business and technology gains.

Market Opportunities

I believe this cooperation agreement opens doors to new solar markets in Europe and beyond. I face some challenges, such as tariffs and local content rules. These can increase costs and slow down growth. However, I see ways to overcome these barriers:

- I work with local manufacturers and research groups to meet local rules.

- I build strong relationships to improve market access.

- I adapt my products to fit different market needs.

By working together, I can reach more customers and help grow the solar industry.

Potential Expansion

I see great potential for expanding this partnership. I can work with the German partner on new products and technologies. We can improve our supply chain and develop better solutions for solar energy. Here is a table that shows some ways we might grow together:

| Aspect | Description |

|---|---|

| Strategic Collaboration | Joint growth strategies and product development |

| Integration | Co-marketing and combining our products |

| Partner Network Expansion | Building a wider network to reach more customers and lower costs |

I stay open to new ideas and welcome partners who want to innovate in solar technology. If you have questions about rigid-flex PCBs or want to discuss a project, please contact me. I enjoy sharing my experience and helping others succeed in the solar field.

2025-09-11

2025-09-11

BEST

BEST

.png)

.png)

.png)

.png)

.png)