You find real value in semi flexible PCB technology for today’s electronics. These boards deliver cost savings, simplify assembly, and unlock new design possibilities. Industry data shows strong market growth, with the semi-flexible PCB market reaching $4,550 million in 2024 and expected to climb to $8.1 billion by 2035.

Explore the main advantages in the table below:

| Advantage | Description |

|---|---|

| Design Flexibility | Ability to bend without performance loss, ideal for compact designs in electronics and automotive. |

| Performance and Durability | High electrical performance withstanding mechanical stresses, suitable for various devices. |

| Cost and Manufacturing Efficiency | More cost-effective than rigid-flex or fully flexible PCBs, balancing flexibility and strength. |

| Reliability | Advanced materials ensure long-lasting performance in extreme environments. |

You gain a competitive edge by understanding these benefits and considering how semi flexible PCB solutions can shape your next project.

Key Takeaways

- Semi-flexible PCBs offer a balance of flexibility and strength, making them ideal for compact electronic designs.

- Choosing semi-flexible PCBs can lead to significant cost savings, with material costs dropping by 30-50% compared to rigid PCBs.

- These PCBs simplify assembly by reducing the number of required components, leading to lower labor costs and improved reliability.

- Semi-flexible PCBs are versatile and can be used in various industries, including consumer electronics, medical devices, and automotive systems.

- Testing and validating your semi-flexible PCB design ensures durability and compliance with industry standards, enhancing product reliability.

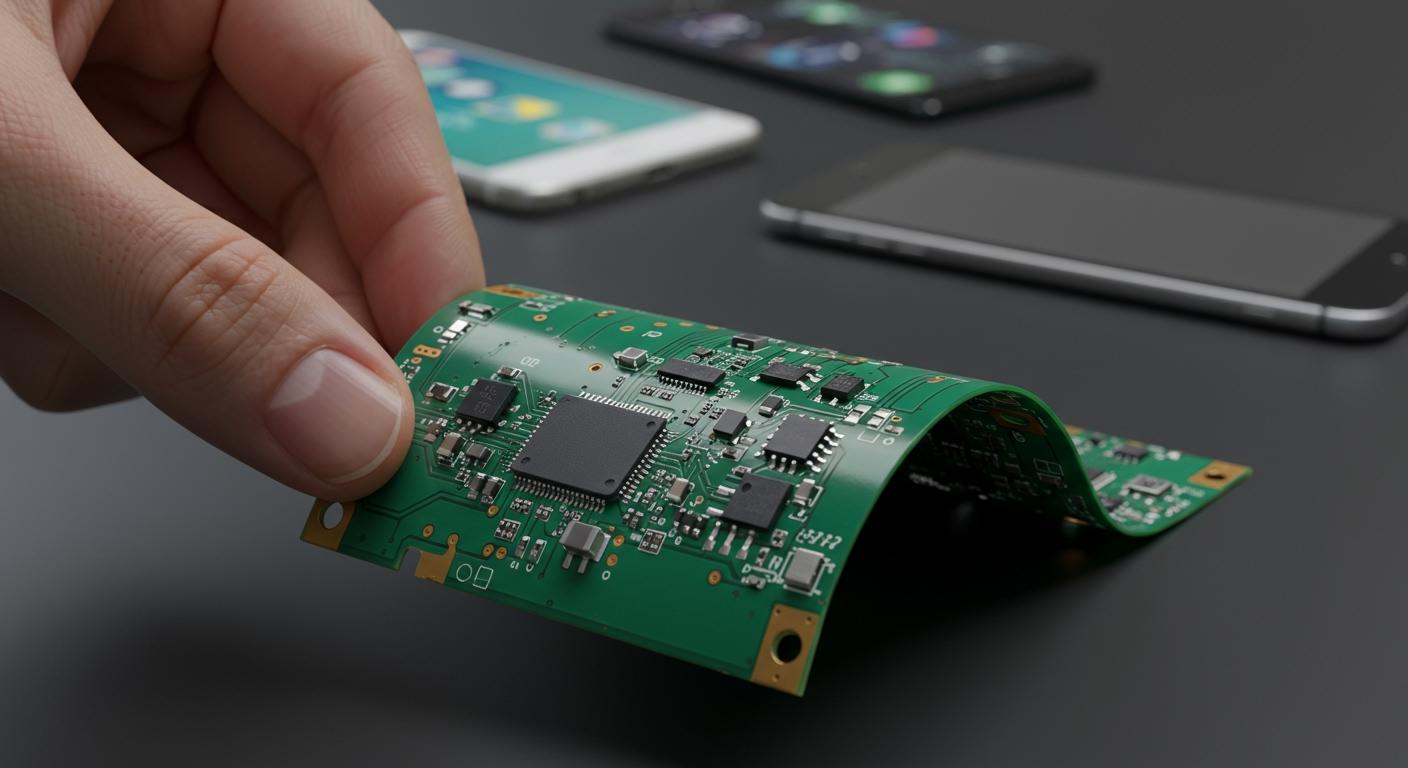

What Is a Semi Flexible PCB?

Structure and Materials

You can think of a semi flexible PCB as a hybrid solution that combines the best features of both rigid and flexible circuit boards. This technology uses a unique structure to deliver flexibility where you need it and strength where you do not. Manufacturers often minimize board thickness to about 0.2-0.8mm, which helps the board bend without breaking. They also avoid sharp corners, which can cause stress and cracks during repeated bending.

To build a semi-flexible pcb, you will find several advanced materials in use. Here is a quick overview:

| Material | Characteristics |

|---|---|

| Polyimide (PI) | Excellent flexibility, heat resistance, and mechanical strength. Common in laminates like DuPontTM Kapton®. |

| PET and PEN | High flexibility and low cost, but lower working temperatures. |

| LCP | Highest temperature resistance, but most expensive. |

Engineers often add reinforced solder masks to protect areas that bend often. They use adhesives to keep layers together and prevent delamination. You may also see stiffening sections in places with dense components, which helps maintain strength. Flex-cuts in strategic spots allow controlled bending, and testing for bend cycle life ensures the board will last.

Comparison with Rigid and Flex PCBs

When you compare a semi flexible PCB to traditional rigid or fully flexible boards, you notice clear differences. Rigid PCBs offer strength but cannot bend at all. Flexible PCBs can twist and fold, but they may lack the mechanical support needed for some applications. Semi-flex pcb technology gives you a balance between these two extremes.

- Rigid boards: Strong, reliable, but not bendable.

- Flexible boards: Bendable, lightweight, but less robust.

- Semi flexible pcb: Offers both flexibility and mechanical strength, making it ideal for compact device design.

You gain the ability to create products that need both durability and flexibility. This technology supports modern electronics where space is tight and reliability is critical.

Cost Benefits of Semi Flexible PCB

Material and Manufacturing Cost

You can achieve significant cost savings when you choose semi flexible pcb designs for your projects. Material costs drop by 30-50% compared to rigid PCBs. Manufacturing expenses also decrease by 20-40%. For example, a semi-flexible pcb might cost $0.50 per square inch, while a rigid-flex design could reach $1.50 per square inch or more. This cost comparison shows why many engineers select semi-flex pcb technology for budget-sensitive applications.

- Lower material costs mean you spend less on each pcb.

- Manufacturing processes for semi flexible pcb designs are simpler, which leads to fewer defects and higher yield rates.

- You benefit from less waste and more efficient production.

| Challenge | Description |

|---|---|

| Solder Masks | Traditional solder masks crack and flake under bending stress; flexible solder masks are needed. |

| Durability in Bending Areas | The number of bends and layers affects durability; thicker boards and more layers reduce flexibility. |

| Design Limitations | Bend angle is limited to 90°; exceeding layer limits increases mechanical stress and failure risk. |

Tip: Choosing semi flexible pcb designs helps you avoid the high costs of premium materials used in fully flexible PCBs.

Assembly and Integration Savings

You can simplify your assembly process and reduce integration costs by using semi-flexible pcb designs. These boards replace multiple rigid PCBs and the connectors or cables that link them. This change leads to a 10-20% reduction in assembly costs. You also save on labor and component expenses because you need fewer parts.

Semi-flexible pcb designs allow you to combine several functions into a single board. This reduces the total number of PCBs required in your device. You spend less time and money on assembly, and your products become more reliable due to fewer connection points.

Note: Streamlining your assembly with semi flexible pcb designs not only saves money but also improves product reliability.

Cost vs. Rigid-Flex and Flex PCBs

When you compare the cost of semi flexible pcb designs to rigid-flex and fully flexible PCBs, you see clear advantages. Flexible PCBs can be 5-10 times more expensive than rigid PCBs because they use premium materials and complex manufacturing processes. The cost of flexible polyimide PCBs ranges from $150 to $300+ per square inch. In contrast, a 4-layer rigid FR-4 PCB costs about $30 per square inch. Semi-flexible pcb designs offer a cost-effective solution for many applications, providing flexibility where needed without the high price tag.

- Semi flexible pcb designs serve as a cost-effective alternative to rigid-flex and flex PCBs.

- You gain flexibility and mechanical strength at a fraction of the cost.

- Cost comparison shows that semi-flexible pcb designs deliver the best balance of performance and cost-effectiveness.

Callout: Semi-flexible pcb technology helps you meet budget goals while maintaining high reliability and design flexibility.

You also help reduce the environmental footprint of your manufacturing process. Energy-efficient production methods can lower emissions by up to 25%. Closed-loop water systems decrease water usage by 40%, and reusing scrap materials reduces raw material demand by 15%. These benefits add to the overall cost-effectiveness of semi flexible pcb designs.

Design Advantages of Semi-Flexible PCB

Compact Device Design

You can achieve a more compact device layout when you use semi flexible PCB solutions. This technology allows you to bend and shape the board to fit tight spaces inside modern electronics. You reduce the need for extra connectors and cables, which often take up valuable room. You also lower the overall weight and thickness of your product, making it easier to design lightweight and portable devices.

| Feature | Semi-Flexible PCBs | Rigid PCBs |

|---|---|---|

| Flexibility | Can bend and flex without breaking | Rigid, cannot bend |

| Connectors and Cables | Reduced reliance, fewer needed | More connectors and cables |

| Device Weight and Size | Lightweight and compact designs | Heavier and bulkier |

| Space Efficiency | High-density interconnections | Limited by rigidity |

You can optimize the thickness of your board to balance flexibility and stability. Mechanical manufacturing works best when you control the remaining thickness within a tolerance range of 0.245mm±0.213mm. This control helps prevent failures during bending and keeps your product uniform. Flexible PCBs help you reduce the weight of your device, which is important for wearables, smartphones, and other portable electronics.

Tip: You can create high-density interconnections and fit more functions into smaller spaces with semi-flexible pcb technology.

Mechanical Strength and Reliability

You gain mechanical strength and reliability when you choose semi-flexible pcb designs. You can test the breaking strength and displacement of your board using uniaxial bending tests. These tests help you find the minimum bending radius and load limits before breakage. You need to calculate the bend radius to avoid cracking or delamination. You should route traces to minimize stress points and place components away from flexible sections.

- Bend Radius: Calculate to avoid cracking or delamination.

- Trace Routing: Minimize stress concentration points.

- Component Placement: Avoid stress on flexible sections.

- Thermal Management: Use techniques to dissipate heat and prevent thermal stress.

- Mechanical Support: Protect flexible sections from excessive bending.

- Bend Testing: Assess durability through repeated bending cycles.

- Thermal Cycling: Evaluate ability to withstand thermal stress.

- Vibration and Shock Testing: Simulate environmental conditions to ensure resilience.

- Environmental Testing: Assess resistance to humidity, salt spray, and chemicals.

- Accelerated Life Testing: Predict long-term reliability under stress.

You can use bending tests, three-point bending tests, and four-point bending tests to measure the mechanical properties of your board. These tests help you ensure your design will last through repeated bending and stress. You should also watch for common failure modes during product testing.

| Failure Mode | Description |

|---|---|

| Plating Voids | Spotty metal deposition inside plated through-holes can lead to opens under thermal or vibration stresses. |

| Insufficient Edge Clearances | Too little spacing between copper traces and board edges risks shorts from condensation or handling damage. |

| Cold Solder & Other Joint Defects | Incomplete reflow or contamination can jeopardize interconnections critical for power transmission. |

| Etching-Related Copper Slivers | Metal fragments can bridge conductors, leading to short circuits from applied condensation. |

| Exposed Inter-Pad Copper | Inadequate solder masking can expose copper pads, making them vulnerable to shorting from moisture. |

Note: You improve reliability by designing for mechanical strength and testing for durability under real-world conditions.

Application Flexibility

You unlock unique design flexibility with semi-flex PCB technology. You can use this technology in many industries where both rigidity and flexibility are needed. You find it in consumer electronics, medical devices, automotive systems, aerospace, and industrial robotics.

- Consumer Electronics: You use semi-flexible pcb designs in smartphones and wearables for compact layouts.

- Medical Devices: You rely on this technology for reliability in small, biocompatible housings.

- Automotive Systems: You benefit from vibration resistance in advanced driver-assistance systems.

- Aerospace and Defense: You choose semi-flexible pcb designs for harsh environments in satellites and avionics.

- Industrial Robotics: You enhance efficiency in robotic arms and machinery.

You can reduce time-to-market for new products by using semi flexible pcb designs. You gain enhanced precision, real-time quality control, and accelerated design iterations. You optimize resource allocation and use predictive maintenance to decrease downtime.

| Aspect | Contribution to Time-to-Market |

|---|---|

| Enhanced Precision | Reduces production errors, leading to faster production cycles. |

| Real-time Quality Control | Minimizes defects, improving product reliability and reducing rework. |

| Accelerated Design Iterations | Allows for quicker prototyping and adjustments, speeding up the development process. |

| Optimized Resource Allocation | Reduces costs and improves efficiency in production. |

| Predictive Maintenance | Decreases downtime, ensuring continuous production flow. |

Callout: You can design products that combine the best features of rigid and flexible PCBs, giving you more options and better performance.

You achieve compactness, mechanical strength, and dimensional stability with semi flexible PCB solutions. You find these advantages especially useful in applications that demand both rigidity and flexibility.

Semi-Flex PCB in Real-World Applications

Consumer Electronics

You see semi flexible PCB solutions in many popular consumer electronics. This technology helps you design portable gadgets with slim profiles and reliable performance. You find semi-flexible pcb in wearable technology, cell phones, and health performance tools. Flexible pcbs allow you to create displays that fit into compact spaces. You can use semi-flex pcb technology to reduce the number of connectors and cables, which makes assembly easier and improves durability.

- Portable gadgets

- Wearable technology

- Cell phone components

- Displays in consumer electronics

- Health performance tools

Tip: You can improve device reliability and save space by choosing semi flexible PCB designs for your next consumer product.

Industrial and Automotive

You rely on pcb solutions that withstand tough conditions in industrial and automotive settings. Semi-flexible pcb offers enhanced durability, which helps your products survive vibrations and temperature changes. You reduce failure points because you use fewer solder joints and connectors. This increases reliability in critical systems. You also gain design flexibility, which lets you create 3D configurations that fit into tight spaces.

- Enhanced durability for harsh environments

- Fewer failure points for improved reliability

- Design flexibility for compact and innovative layouts

| Benefit | Description |

|---|---|

| Durability | Withstands vibration and temperature fluctuations |

| Reliability | Fewer connectors and solder joints minimize risk |

| Design Flexibility | Enables 3D shapes for space-saving designs |

Note: You can boost product performance and reliability in industrial and automotive applications by using semi-flexible pcb.

Medical and Wearables

You find semi flexible PCB solutions in advanced medical and wearable devices. Flexible pcbs are essential for products like glucose monitors and ECG patches. These devices need to bend and conform to the body for continuous monitoring. You benefit from lightweight pcbs, sometimes under 0.5 grams, which increase patient comfort. You also see semi-flex pcb technology in medical equipment that requires precise temperature control and protection for sensitive components.

| Device/Application | Description |

|---|---|

| Injection needle tip protection circuit board | Protects needle tips in medical applications |

| Medical equipment temperature control circuit board | Regulates temperature in medical devices |

| Portable blood pressure meter display circuit board | Displays readings for portable monitors |

Manufacturers must meet strict standards for medical pcbs. You need to comply with IEC 60601 and other global safety requirements to ensure device safety and performance.

Callout: You can trust semi flexible PCB designs to deliver safety, comfort, and reliability in medical and wearable devices.

Long-Term Value and Lifecycle Cost

Total Cost of Ownership

You need to consider the total cost of ownership when choosing pcb solutions for your project. Semi-flex pcb technology offers a lower total cost compared to rigid and flex pcbs, especially for low to medium production volumes. You save money on materials and manufacturing, which helps you keep costs down during the early stages of product development. If you start with semi-flex for prototypes, you can refine your pcb design considerations without spending too much.

Tip: For production volumes under 10,000 units, semi-flex pcbs maintain a clear cost advantage.

You also benefit from controlled flexibility, which reduces the need for extra connectors and cables. This leads to faster assembly and fewer potential failure points. In high-volume production, the cost difference between semi-flex and rigid-flex pcbs becomes smaller because of economies of scale. However, for most consumer and industrial products, semi-flex pcbs remain the most cost-effective choice.

Here is how total cost of ownership compares:

- Semi-flex pcbs are more cost-effective for low to medium production volumes.

- Rigid-flex pcbs may reduce assembly costs by eliminating connectors, but their initial cost is higher.

- Time-to-market improves with semi-flex pcbs due to simplified assembly and faster production.

Scalability and Maintenance

You gain scalability advantages with semi-flex pcb technology. Manufacturers can increase production volumes easily because the manufacturing process only adds one step compared to standard double-sided or multilayer pcbs. You can integrate complex circuits in a compact form, which supports efficient scaling.

- Cost reduction comes from fewer connectors and a simplified assembly process.

- Semi-flex pcbs use epoxy resin FR-4 material, making them less expensive than traditional flexible or rigid-flexible pcbs.

You also improve maintenance with controlled flexibility. Fewer connectors mean fewer points of failure, which simplifies repairs and reduces downtime. When you plan your pcb design considerations, you ensure that your products remain reliable and easy to service over their lifecycle.

Note: Semi-flex pcbs deliver long-term value by combining cost savings, scalability, and reliable performance.

You gain cost savings and design flexibility with semi-flex. You achieve compact layouts and reliable signal performance. You should consider semi-flex when you need both rigidity and flexibility in your device. You must evaluate rigid and flexible area planning, minimize flex bends, and check component placement. You need to follow IPC standards for testing and quality. You should weigh trade-offs like limited bending and increased design complexity. You can use semi-flex to optimize technology for your next project.

- Rigid and flexible area planning

- Minimize flex bends and transitions

- Component placement and clearance

- Layer stack balancing

- Trace and via design

- Flex termination and anchoring

- Flexibility testing and prototyping

| Test Type | Class 1 | Class 2 | Class 3 |

|---|---|---|---|

| Electrical continuity and isolation tests | Minor deviations allowed | Tighter tolerances | Zero defects tolerated |

| Thermal cycling and environmental stress tests | Fewer cycles | Extended cycles | Harsh conditions |

| Mechanical bending and flexibility tests | Minor wear allowed | No visible damage | No cracks or delamination |

Tip: You should validate your semi-flex design with flexibility testing and industry standards before production.

2025-10-23

2025-10-23

BEST

BEST

.png)

.png)

.png)

.png)

.png)