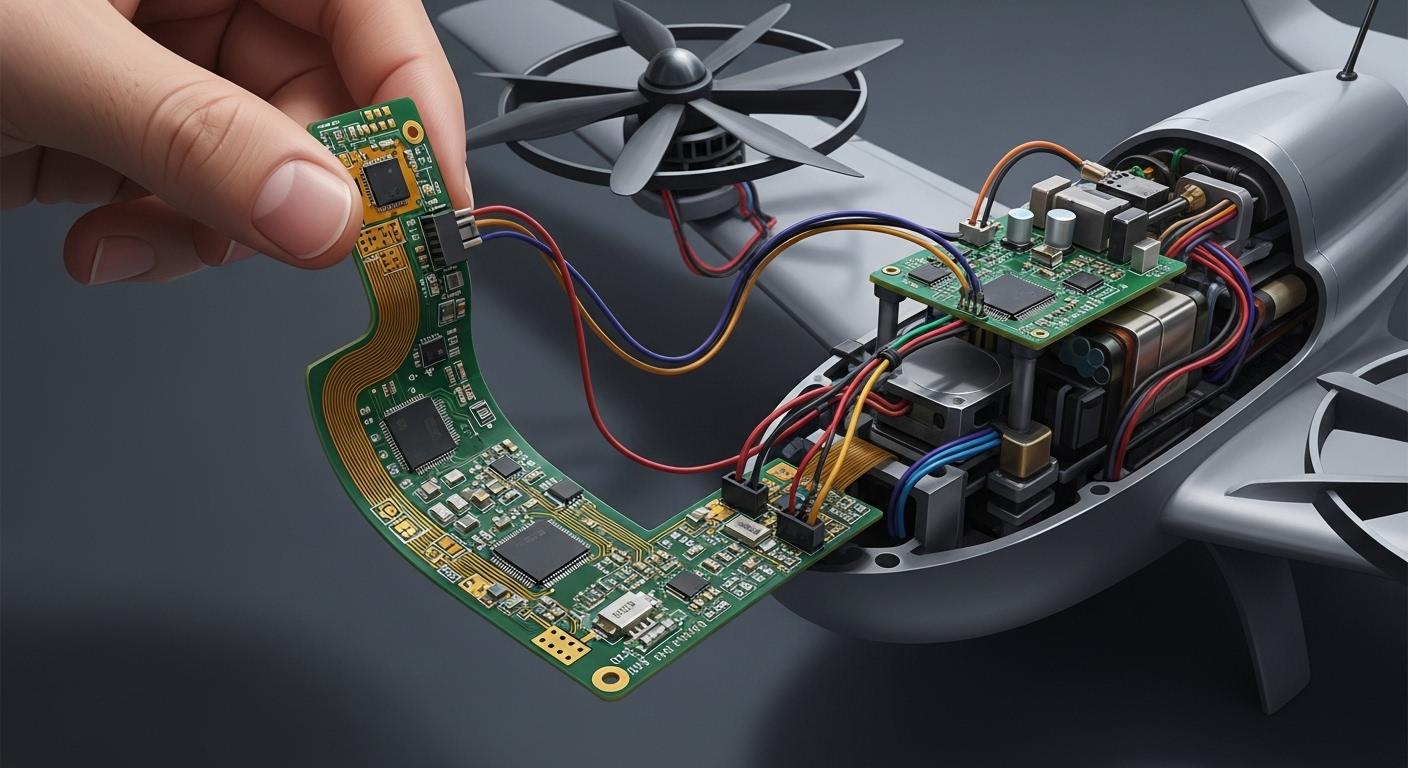

You need a custom fpcb design to make your rc aircraft lighter. It also makes it more reliable and easier to upgrade. Flexible materials help you fit the flight controller in small spaces. Good stack-up and material choice stop damage during flight. When you build a flight control pcb, you must pick parts that work together. These parts should support every sensor you need. Careful design keeps your controller safe. It also helps your aircraft fly smoothly.

Key Takeaways

- Pick light and bendy materials like polyimide for your FPCB design. This keeps your RC aircraft light and strong.

- Choose only the features and sensors your aircraft needs. This makes flying safe and smooth without extra weight.

- Plan your circuit design with care. Put important parts close together to help it work better and stop interference.

- Test your flight controller using cheap prototypes. This helps you find and fix problems before you finish building.

- Make sure you use good materials and check them with inspection tools. This helps your flight controller work well during flights.

Requirements and Components

Essential Features

When you make a flight controller for your rc aircraft, you should pick features that help your plane fly safely. These features also help your plane fly smoothly. The table below lists the most important things to include in your controller:

| Feature | Description |

|---|---|

| Sensors | Has gyroscope (MPU-6000), barometer (BMP388), and GPS interface (Matek M8Q-5883). |

| Power Management | Uses a 5V rail from Vbatt, special 3V3 LDOs for MCU and sensors, and keeps video clear. |

| Routing | Made to work with TPU stack, and fits well with layout limits. |

| Board Form Factor | Uses a 30.5×30.5mm mounting pattern, has tabs for connectors, and helps heat escape. |

| PCB Stack Up/Layout | PCB is 1mm thick, has a solid ground plane, and helps signals and power stay strong. |

Tip: Pick features that match what your rc plane needs. This stops extra weight and keeps your system working well.

Sensor Selection

You need good sensors to make your flight controller work right. Sensors help your controller know how your rc aircraft moves. The table below shows two types of sensors:

| Sensor Type | Description |

|---|---|

| 6-axis IMU | Has a 3-axis MEMS gyro and a 3-axis accelerometer. It finds movement and helps keep flight steady. |

| 9-axis IMU | Adds three magnetometer sensors to the 6-axis IMU. It checks magnetic fields and helps stop drifting. |

A 6-axis IMU works for most rc aircraft. If you want better heading control, use a 9-axis IMU. This helps your controller keep the plane steady, even when it is windy.

Power and Communication

Your flight controller needs steady power. Use a 5V rail from your battery. Add 3.3V LDOs for the microcontroller and sensors. This setup keeps your controller safe from voltage spikes. Good power management also keeps your video feed clear.

For communication, pick connectors that fit your board. Make sure your controller works with the protocols your rc system uses. Good connections help you control your rc planes without losing signal.

Flight Controller Architecture

Circuit Design

You need a strong circuit design for a good flight controller. Put important parts close together. This makes the controller work better. Keep analog parts away from digital parts. This lowers interference. Put power parts near each other. This reduces inductance. Always use bypass capacitors near power pins. They stop current spikes.

- Put high-speed signal traces next to ground planes.

- Make power traces short and wide.

- Route differential pairs together with space between them.

- Connect each ground pin to the plane by itself.

Tip: A good layout helps your betaflight flight controller avoid noise. It keeps your plane stable in the air.

Signal Integrity

Signal integrity means signals stay clean and strong in the flexible PCB. Bending can change the impedance of traces. This may cause signal reflections. Keep traces short. Do not cross them. Use the right trace widths for controlled impedance. Route high-speed signals as differential pairs. This helps block noise.

- Keep analog and digital traces apart.

- Use guard traces or isolation for important signals.

- Pick the right substrate material for better signals.

- Watch out for electromagnetic interference. It can disrupt signals.

A controller with good signal integrity helps your aircraft respond fast and accurately.

ESD Protection

Electrostatic discharge (ESD) can hurt your controller. ESD can burn or melt parts. It can also cause slow damage over time. Use ESD protection devices on all input and output lines. Use a single-point ground to lower ground loops. Use special ground planes for low-inductance return paths.

- Add ESD diodes to sensitive pins.

- Keep separate ground planes for analog and digital sections.

Note: Good ESD protection makes your flight controller last longer. It keeps your plane flying safely.

If you want your controller to last, follow these steps. Share your questions or tips in the comments. Help others build better RC aircraft!

FPCB Design and Layout

Making a flexible PCB for your flight controller needs good planning. You want the board to bend but not break. It should last for many flights. A good fpcb design keeps your rc planes light and strong. Here are the main steps in this process.

Material Choice

You must choose the best material for your fpcb design. The material changes how much your board bends and how long it lasts. Polyimide is the most used for flight controller boards. It can take high heat and keeps its shape. Polyester costs less but does not handle heat well. PTFE is great for high-frequency signals, but it is very expensive.

Here is a table to compare the most common materials:

| Material | Properties |

|---|---|

| Polyimide (PI) | Handles high heat, strong electrical and mechanical properties, but costs more and absorbs water. |

| Polyester (PET) | Like PI but does not handle heat, good for room temperature use. |

| PTFE | Very costly, used for high-frequency products with low dielectric constant. |

Polyimide gives your fpcb design the best mix of bending and strength. It lets you fit your controller into small spaces in your drone or plane. The right material also helps your board survive heat and stress during flight.

You can see how different materials change flexibility and strength in the table below:

| Material Type | Impact on Flexibility | Impact on Durability |

|---|---|---|

| Polyimide | Makes bending and fitting easier | Stays strong under heat |

| Low-loss materials | Makes signals move faster | Keeps working under heavy use |

| Thermally conductive | Helps get rid of heat | Lasts longer when hot |

Tip: Pick polyimide for most flight controller boards. It gives the best mix for rc and drone projects.

Stack-Up

Stack-up means how you put the layers in your fpcb design. The right stack-up keeps your board strong and helps signals move fast. A balanced stack-up stops your board from bending the wrong way. Power and ground planes should be close together. This setup lowers noise and keeps your controller working well.

Here are some common stack-up types for flexible PCBs:

| Configuration Type | Description |

|---|---|

| Odd Number of Layers | Starts with one-sided flex for best bending. |

| Polyimide Core Stack-up | Lets you put parts on both sides, saves space. |

| 3-layer Flex | Ground mesh outside, signals inside for better control. |

| Solid Ground Plane | Used on outside layers to keep reference planes above and below lines. |

A good stack-up helps your flight controller handle stress from flying and from electricity. Here are some best practices:

- Keep your layer stack-up even to stop warping.

- Put power and ground planes close to lower noise.

- Use power planes in multi-layer boards for balance.

Note: A solid stack-up makes your fpcb design last longer in rc planes and helps your controller work better.

Copper Placement

Copper placement is very important in fpcb design. You need to plan where to put copper traces and planes. Good copper placement keeps your signals clean and your board strong. It also helps your controller survive bending and shaking during flight.

Here are some best practices for copper placement:

| Best Practice | Description |

|---|---|

| Coplanar Ground Traces | Put ground lines next to signal traces for extra protection. |

| Route Only Over Solid Sections | Route signals only over solid copper to keep signals strong, especially for fast lines. |

| Closely Spaced Differential Pairs | Keep paired traces close to control impedance without making them wide. |

| Bends Affect Impedance and Losses | Bending can change impedance and make signals weaker. |

| Need for EM Field Solver | Use special tools to check impedance on complex planes. |

Do not route signals over areas that bend a lot. Bending can squeeze the polyimide and change how signals move. This can cause problems with your flight controller. Always keep fast signals over solid copper. Use ground traces next to signals to block noise.

Tip: Plan your copper placement to make your fpcb design tough. This helps your controller work well every flight.

A smart fpcb design gives your rc planes an advantage. You get a lighter, stronger, and more reliable flight controller. If you have questions or want to share tips, leave a comment below!

Manufacturing and Testing

Flight Control PCB Prototyping

You should build and test your flight controller before using it. First, make your schematic and layout with Kicad or STM32CubeIDE. These tools help you organize your flight control pcb and find mistakes. When your design is ready, order prototypes from JLCPCB. You can get ten double-sided boards for just $2, which saves money. Shipping is extra, and DHL costs about $18 but is faster. Airmail is cheaper, but you wait longer for delivery. Fast prototyping helps you test your controller quickly and fix problems before you finish building.

Tip: Try low-cost prototyping to test new ideas and make your flight controller better without spending a lot.

Assembly

You need to put your flight controller together carefully. Flexible PCBs need special care when you build them. The spot where rigid and flexible parts meet is tricky. You must design these areas well so they do not break. Controlled impedance is needed for good performance with flexible materials. Reliable connections are important, and sometimes you skip connectors to stop failures. This means you need careful soldering and placement.

| Challenge Description | Details |

|---|---|

| Transition from rigid to flexible areas | Needs careful design for reliability |

| Maintaining controlled impedance | Essential for performance with flexible materials |

| Reliable connections without connectors | Reduces failure modes, needs precise assembly techniques |

You can make your assembly better by using the right tools and following good steps. This helps your controller last longer and work better in your rc aircraft.

Quality Assurance

You want your flight controller to work every time you fly. Quality assurance starts with using good materials. Bad materials can cause problems like bubbles and bending. Production machines must be up to date for good results. You need to check each step to catch problems early. Some factories lower prices by skipping steps, but this makes controllers less reliable.

- The FIDES method helps you find failures that normal tests miss. Engineering teams use it for reliable flight controllers.

- Use inspection tools at every step to keep quality high.

- Follow strict rules for making to stop defects.

Note: Careful checks and good materials make your flight controller safe and dependable.

If you follow these steps, your flight controller will work well and last for many flights. Share your tips or ask questions below to help others with their flight control pcb projects.

You need a good FPCB design to keep your rc aircraft light and working well. Start by choosing the best features and sensors. Test your flight controller after you build it. New tools and fast prototyping help you do better.

- You use an outside battery to power your board. You can control up to 8 servo motors.

- You read sensor data and send live info to the ground station.

JLCPCB makes it easy to order test boards. You can check your design before building. This helps you make fewer mistakes and finish your project better.

2025-10-24

2025-10-24

BEST

BEST

.png)

.png)

.png)

.png)

.png)