Choosing the best flex pcb for a drone goes beyond picking any circuit board. Each drone, whether used for delivery in Berlin or aerial photography over Munich, needs a flex pcb that matches its unique demands. When someone selects a drone flex pcb, they must consider size, weight, and the specific pcb materials. A high-quality flex pcb can boost durability and performance, especially in a uav. Many in Germany trust a drone flex pcb for its ability to fit tight spaces and handle vibration. Avoiding mistakes starts with smart choices. For questions, reach out at sales@bestfpc.com.

Key Takeaways

- Choose flex PCBs that fit your drone's size, weight, and mission to boost performance and battery life.

- Polyimide flex PCBs offer strong flexibility, heat resistance, and durability for tough drone environments.

- Use rigid-flex PCBs to combine strength and flexibility, helping drones handle vibration and tight spaces.

- Design your PCB with the right stackup, bend radius, and support to keep circuits safe and reliable.

- Test and improve your flex PCB regularly to ensure it bends well and keeps the drone flying safely.

Drone Requirements

Purpose and Application

Every drone starts with a clear purpose. Some drones capture stunning aerial photos over German cities, while others deliver packages or inspect wind turbines. Each drone specific application shapes the choice of drone pcb and other drone parts. For example, a drone used for real-time video streaming in Berlin needs a pcb that supports high-resolution video and stable data transmission. The table below shows how different requirements affect drone functionality:

| Aspect | Application Requirement | Impact on Drone Functionality |

|---|---|---|

| Video Compression Standards | High-res video streaming (UHD) | H.265 (HEVC) enables 4K/8K video with less bandwidth |

| Modulation Techniques | Range, data rate, interference | FM, AM, FHSS, DSSS, OFDM balance data rate, resistance, and power use |

| Frequency Bands | Range, penetration, data needs | 433 MHz for long range; 2.4 GHz/5.8 GHz for high data rates |

| Real-Time Video Feed | Cinematic, surveillance, inspections | Custom data systems for real-time, high-quality video feeds |

| Transmission Challenges | Bandwidth, latency, interference, security | Design choices reduce video loss, lag, and signal issues |

| Advanced Technologies | Performance in tough conditions | Dual-frequency, AI-based modulation, and 5G boost drone performance |

Tip: Matching the right drone pcb to the application ensures the drone meets its mission without wasting battery life or space.

Size and Weight

Drones come in all shapes and sizes. A racing drone in Munich needs a lightweight pcb to stay agile. A delivery drone needs a compact design to fit more battery and cargo. The drone pcb must fit tight spaces and keep the drone light. Polyimide flex pcb options help reduce weight and allow creative layouts. Less weight means longer battery life and better flight times. Every gram counts when optimizing drone performance.

Power and Performance

Battery life drives every drone mission. The drone pcb must use power efficiently to extend battery life. High-performance drones need a pcb that handles fast data, strong motors, and stable connections. The design should support the right battery, sensors, and interfaces. A good pcb design prevents overheating and power loss. Rigid-flex pcb options can add strength without extra weight, perfect for drones facing vibration or rough landings. Choosing the right drone pcb keeps the drone flying longer and safer.

For more advice on matching your drone pcb to your needs, contact sales@bestfpc.com.

Drone Flex PCB Materials

Polyimide (PI)

Polyimide stands out as the top choice for drone flex pcb applications. Many engineers in Germany rely on this material for drones that must perform in tough environments, such as inspecting wind turbines along the North Sea or delivering medical supplies in Berlin. Polyimide flex pcb materials offer a unique mix of flexibility, strength, and thermal stability. These features help drones handle rapid temperature changes, constant vibration, and tight installation spaces.

Here’s a quick look at why polyimide leads the pack:

| Performance Metric | Description |

|---|---|

| Working Temperature Range | Extremely wide range from -269°C to over 400°C, enabling reliable operation in extreme environments. |

| Flexibility and Shape Conformability | Can bend, twist, and fit irregular surfaces without damage, perfect for dynamic drone movements. |

| Chemical and Solvent Resistance | Stands up to fuels, hydraulic fluids, and corrosive agents, ensuring stable performance in harsh settings. |

| Vibration and Shock Resistance | Absorbs vibration and shock, preventing cracks and keeping connections stable during flight. |

Polyimide-based flex pcb materials, like Pyralux, have proven themselves in defense drones. These flexible pcbs allow for quick assembly and lightweight builds, which are essential for drones that need to deploy fast or operate in remote areas. Over decades, these materials have shown long-term reliability, with no field failures reported in demanding aerospace and defense missions.

Tip: For drones flying in Germany’s unpredictable weather, polyimide flex pcb options help maintain performance and reliability, even when temperatures swing or conditions get rough.

Polyester (PET) and Others

Polyester (PET) offers a cost-effective alternative for less demanding drone flex pcb needs. PET-based flexible pcbs work well in hobby drones or educational kits where extreme temperatures and harsh chemicals are not a concern. PET provides decent flexibility and can handle basic drone circuits, but it does not match polyimide’s thermal or chemical resistance.

Some advanced drone designs use high-frequency materials for specialized tasks, such as real-time video streaming or radar imaging. These materials support high-speed signals and reduce signal loss, which is important for drones used in mapping or surveillance across German cities.

- When to choose PET or other materials?

- Use PET for simple, low-cost drones.

- Choose high-frequency materials for drones with advanced sensors or communication systems.

Rigid-Flex Options

Rigid-flex pcb designs combine the best of both worlds. They use rigid sections for mounting heavy components and flexible sections for routing circuits through tight spaces. This approach works well for complex drones, such as those used in industrial inspections or multi-rotor delivery systems in Germany.

A rigid-flex pcb stackup allows engineers to create compact, lightweight drones without sacrificing durability. The rigid areas provide support for connectors and processors, while the flexible parts bend around corners or fit into small compartments. This design reduces the need for bulky wiring and lowers the risk of connection failures during flight.

Note: Rigid-flex options help drone manufacturers in Germany build reliable, space-saving drones that can handle vibration, shock, and frequent movement.

Choosing the right material and stackup for a drone flex pcb makes a big difference in performance, reliability, and cost. For help with selecting the best flex pcb for your drone project, reach out to sales@bestfpc.com.

Flex PCB Benefits for Drones

Weight Reduction

Flex pcb technology brings huge benefits to drone design, especially when it comes to weight reduction. Engineers in Germany often look for ways to make drones lighter so they can fly longer and carry more advanced cameras or sensors. By switching from multiple rigid boards to a single rigid-flex pcb, one micro air vehicle infrared imaging system dropped its weight from 3 pounds to less than 3 ounces. That’s a 95% reduction! This change allowed the drone to keep its battery life high and its dynamic performance strong. Less weight means the battery works less, so the drone can stay in the air longer. Flex pcb designs help drones meet strict payload limitations without losing functionality or integrity.

Durability and Vibration Resistance

Drones face constant movement and vibration, especially during dynamic maneuvers or windy flights over German cities. Flex pcb materials handle these challenges well. They bend and flex with the drone’s frame, absorbing shocks that could damage traditional boards. This flexibility protects the integrity of the circuits, even after thousands of cycles of dynamic flexing. Flex pcb designs also resist cracking, so the drone keeps working even after rough landings. The durability of flex pcb means fewer repairs and longer drone life, which saves time and money for drone operators.

Space Optimization

Space inside a drone is always tight. Flex pcb solutions let engineers bend circuits around corners, under batteries, or through narrow arms. This ability to bend and twist means designers can fit more features into smaller drones. In Germany, many drones need to carry extra sensors for mapping or inspection. Flex pcb makes this possible by freeing up space and reducing the need for bulky connectors. The result is a compact, efficient layout that keeps the battery safe and improves the drone’s dynamic response. Flex pcb also helps maintain signal integrity, even in complex, multi-layer designs.

Tip: Flex pcb offers unmatched benefits for drones that need to bend, flex, and perform in dynamic environments. For more advice, contact sales@bestfpc.com.

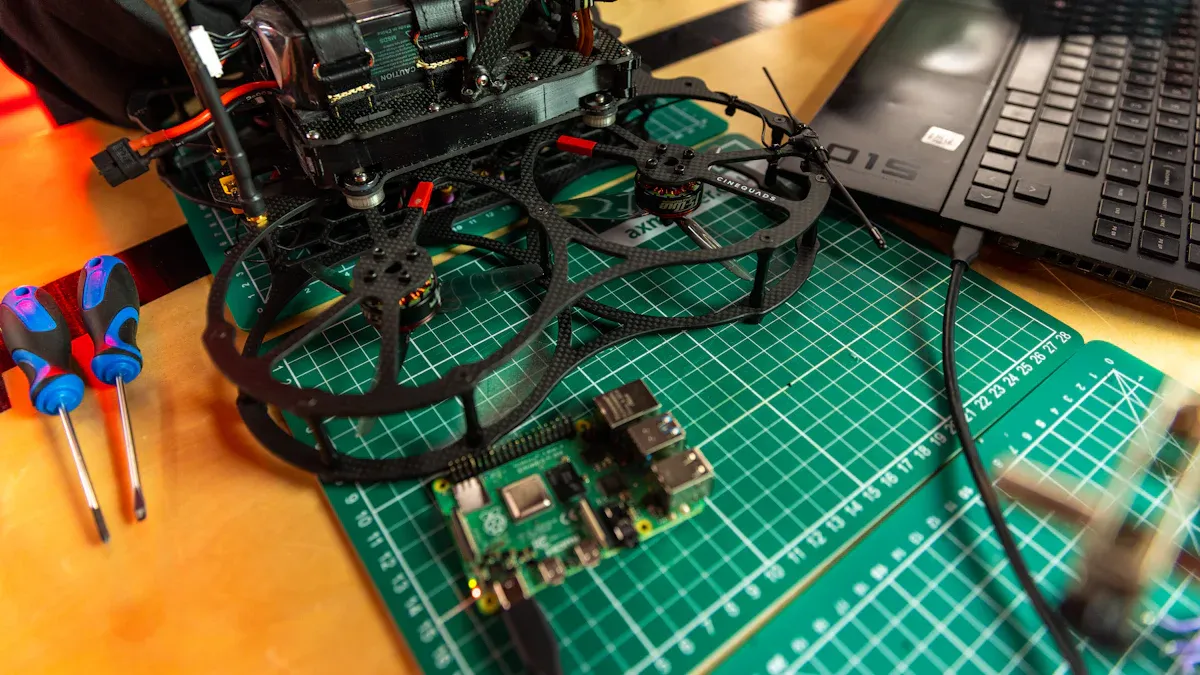

Drone PCB Design

Designing a drone pcb takes careful planning. Every drone, whether it flies over Berlin for mapping or inspects wind turbines on the North Sea, depends on a smart flex pcb design. The right choices in stackup, support, bend radius, and layout help drones stay light, reliable, and ready for dynamic missions.

Stackup and Layers for FPC design & fabrication

Stackup forms the backbone of any drone pcb. Engineers in Germany often choose a flex pcb stackup to fit tight spaces and reduce weight. A good stackup lets the drone pcb handle more circuits in less space. High-density interconnect (HDI) pcbs allow more wiring and components on smaller boards. This supports miniaturization, which is critical for drones that need to carry cameras or sensors without extra bulk.

- HDI pcbs use micro-vias and stacked vias. These features create compact, multi-layer designs.

- Shorter signal paths improve speed and reduce latency. This matters for drones that stream video or process data in real time.

- Better thermal management and lower power use keep the drone running longer.

- HDI pcbs support high-speed materials and finer lines, which protect signal integrity.

A flex pcb stackup also helps with dynamic drone movements. The layers can bend and twist, letting the drone fit more features into a small frame. For drones in Germany, this means more flight time and better performance, even in tough weather.

Stiffeners and Support for FPC PCB

Flex pcb design often needs extra support in key areas. Stiffeners add strength where the drone pcb holds heavy parts, like processors or connectors. These supports keep the board from bending too much and protect the integrity of the circuits. In drones that land hard or face strong winds, stiffeners prevent damage and keep the drone pcb working.

- Stiffeners can be made from materials like FR4 or stainless steel.

- They get placed under connectors, chips, or mounting holes.

- Good placement of stiffeners keeps the flex pcb light but strong.

Engineers in Germany use stiffeners to balance flexibility and support. This helps drones survive dynamic flights and rough landings. The right support means fewer repairs and longer drone life.

Bend Radius of Flexible PCB

Bend radius is a key part of flex pcb design. The minimum bend radius tells how tightly the board can bend without damage. If the drone pcb bends too much, it can crack or lose signal integrity. For drones with moving arms or folding parts, knowing the minimum bend radius is vital.

- The minimum bend radius depends on the number of layers and the thickness of the flex pcb.

- A smaller minimum bend radius allows tighter bends, which saves space.

- Too tight a bend can break the copper traces or damage the insulation.

Designers in Germany often test the minimum bend radius during prototyping. This ensures the flex pcb can handle dynamic movements without failure. For drones that need to fold or fit into small cases, a safe minimum bend radius keeps the circuits working.

Tip: Always check the minimum bend radius for your flex pcb design. This protects the drone pcb from cracks and keeps the drone flying safely.

Soft Board Layout and Interfaces

The layout of a drone pcb affects everything from power use to signal integrity. A smart layout places key components of drone pcb, like processors and sensors, in the best spots. This reduces signal loss and keeps the drone running smoothly.

- Track width matters for power and signal flow. If the tracks are too thin, the drone pcb can overheat or lose efficiency.

- The number of UART ports, processor type, and firmware compatibility all shape the layout.

- Power budget estimation helps balance battery life and performance.

- Good layout supports dynamic drone tasks, like real-time video or sensor data.

Engineers in Germany often use HDI pcbs for complex layouts. These boards support more features in less space. They also help with thermal management, which is important for drones that fly in hot or cold weather.

A well-planned flex pcb design keeps the drone light, reliable, and ready for any mission. It also makes repairs easier and supports upgrades. For help with your drone pcb or flex pcb design, contact sales@bestfpc.com.

Flex PCB & Rigid-flex PCB Manufacturing and Quality

Flex PCB Supplier Evaluation

Choosing the right supplier shapes the success of any drone project in Germany. Drone makers look for suppliers who understand the demands of custom pcb solutions and can deliver consistent quality. A good supplier tests each pcb for moisture resistance, thermal stability, and mechanical strength. These tests help drones survive rain in Hamburg or cold winds near the North Sea. Suppliers often use polyimide substrates and protective coatings to stop delamination and corrosion. They also follow strict standards, like IPC 6013, to ensure each pcb meets the right class for its application—whether for a hobby drone or a high-reliability industrial model.

Here’s a quick look at key performance metrics:

| Performance Metric | Description |

|---|---|

| IPC 6013 Class Levels | Defines reliability for consumer, industrial, or aerospace drones |

| Plating Quality | Ensures strong connections at pads and vias |

| Conductor Quality | Maintains signal integrity and power delivery |

| Environmental Resistance | Protects against moisture, heat, and vibration |

| Mechanical Durability | Withstands shocks and mechanical stress |

| Manufacturing Precision | Delivers accurate dimensions for custom pcb fit |

Flex PCB & Rigid flex PCB Prototyping and Samples

Prototyping helps drone engineers in Germany catch problems early. They order samples to test the pcb under real-world conditions. Functional testing checks if the pcb works as planned. In-circuit testing finds shorts or bad connections. Automated optical inspection spots visual defects, while X-ray inspection reveals hidden issues in multi-layer designs. Environmental testing, like thermal cycling and humidity exposure, shows how the pcb will perform in harsh weather. These steps ensure the custom pcb will last through tough flights and rough landings.

Tip: Always ask suppliers for detailed test reports before moving to full production.

Bendable Circuit Board Cost and Lead Time

Cost and lead time matter for every drone project. Flexible pcb and rigid-flex designs help reduce weight and improve flight time, but they can cost more than standard boards. Early consultation with suppliers helps avoid delays and keeps the supply chain moving. In Germany, drone makers often balance price with the need for reliable, high-quality pcb solutions. Fast prototyping and clear communication with the supplier keep projects on schedule. Choosing a supplier with experience in drone pcb design ensures better results and fewer surprises.

For more advice or to discuss your next drone pcb project, reach out at sales@bestfpc.com.

Standards and Compliance

Flexible Circuits Industry Standards

Drone makers in Germany face strict rules. They must follow industry standards to ensure every drone meets legal and technical requirements. Standards like IPC 6013 and ISO 9001 set the bar for quality and integrity in drone PCB manufacturing. These rules help engineers create boards that last longer and work better in real-world conditions.

Many German drone companies use flex and rigid-flex PCBs because these designs meet both European and international standards. For example, drones that inspect bridges in Hamburg or deliver medicine in Berlin need high signal integrity for safe and accurate data transfer. Flex PCBs help maintain this level of performance, even in tough environments.

Note: Following industry standards protects the integrity of the drone’s electronics and helps companies avoid costly recalls or failures.

FPC Safety and Reliability

Safety always comes first in drone design. Engineers in Germany test every PCB for reliability before sending drones into the sky. They check for issues like overheating, vibration, and moisture. Flex PCBs offer strong integrity, which means fewer failures during flight.

A reliable drone can handle sudden weather changes or rough landings. This matters for drones used in search and rescue or industrial inspections. Rigid-flex PCBs add another layer of safety by combining strength with flexibility. These boards keep connections secure and circuits stable, even after hundreds of flights.

Here’s a quick checklist for boosting reliability and integrity in drone PCBs:

- Use certified materials and trusted suppliers.

- Test for high signal integrity in all operating conditions.

- Inspect for cracks, corrosion, or weak solder joints.

- Document every step for traceability.

German drone operators trust flex PCBs for their proven reliability and integrity. For more details or help with compliance, reach out at sales@bestfpc.com.

Testing and Validation

Integration in Drone

Engineers in Germany often start by fitting the flex PCB into the drone’s frame. They check if the board can bend around tight corners and fit under the battery compartment. The flex PCB must bend without cracking, especially near the arms where the drone faces the most stress. Some drones, like those used for bridge inspections in Hamburg, need the PCB to bend several times during assembly. The team tests if the board can bend repeatedly while keeping all connections stable. They also make sure the battery wires stay secure, even when the drone bends its arms for storage or transport. This step helps confirm that the flex PCB matches the drone’s unique shape and battery placement.

Functional Testing

After integration, the team runs a series of functional tests. They power up the drone and check if every system responds. The battery gets charged and discharged to see if the flex PCB can handle the current. Engineers bend the drone’s arms and watch for any signal loss or power drop. In Germany, some teams use piezoelectric sensors on the drone arms to record vibration signals. These sensors help detect if the flex PCB fails when the drone bends during flight. The table below shows how engineers use Recurrence Quantification Analysis (RQA) indicators to measure performance:

| RQA Indicator | Description | p-value | Use in Testing |

|---|---|---|---|

| DET | Determinism | <0.05 | Detects damage during bend |

| L | Avg. diagonal line length | <0.05 | Monitors signal during bend |

| Lmax | Max diagonal line length | <0.05 | Finds severe bend failures |

| ENTR | Entropy | <0.05 | Checks battery signal changes |

| LAM | Laminarity | <0.05 | Tracks stable bends |

| TT | Trapping Time | <0.05 | Measures bend duration |

These tests give a clear baseline for undamaged conditions. If the drone bends too much, the sensors pick up changes right away. This method helps German drone makers spot problems before they cause a battery failure or crash.

Iteration and Improvement

Testing does not stop after the first flight. Engineers review the results and look for weak spots where the flex PCB bends too sharply or the battery connection loosens. They may adjust the design, moving traces away from high-bend areas or adding support near the battery. Each new version gets tested again, with the team bending the board and cycling the battery to check for improvements. This cycle of testing and tweaking helps German drone companies build drones that last longer and fly safer. They keep records of every bend and battery test, making it easier to spot trends and fix issues fast.

Tip: Regular testing and smart design changes help drones in Germany handle every bend and keep the battery running strong. For more advice, contact sales@bestfpc.com.

Selecting the right flex PCB for a drone takes careful steps. Every drone project in Germany, from aerial mapping to delivery, needs a PCB that matches its mission. The guide helps users check each step, from choosing materials to testing how the board will bend inside the drone. When a drone faces tough weather or must bend around tight spaces, a flex PCB keeps it light and reliable. Careful planning and testing help every drone fly longer and safer. For more help, reach out at sales@bestfpc.com.

2025-06-13

2025-06-13

BEST

BEST

.png)

.png)

.png)

.png)

.png)